mud scraper for drilling tool

A mud scraper and drilling tool technology, which is applied in the direction of cleaning equipment, earthwork drilling, wellbore/well parts, etc., can solve the problems of affecting the work of drill pipes, affecting production safety, and not being able to fit, so as to save labor time, The effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

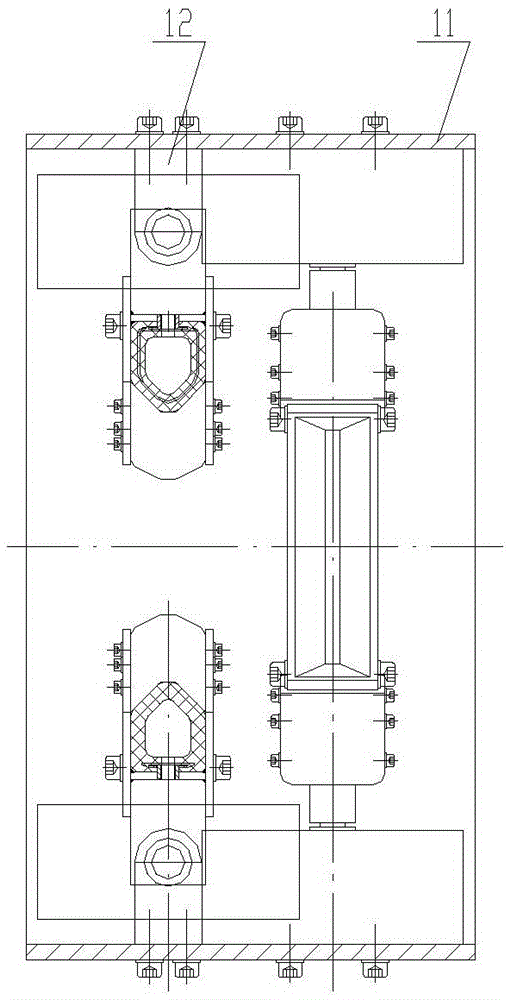

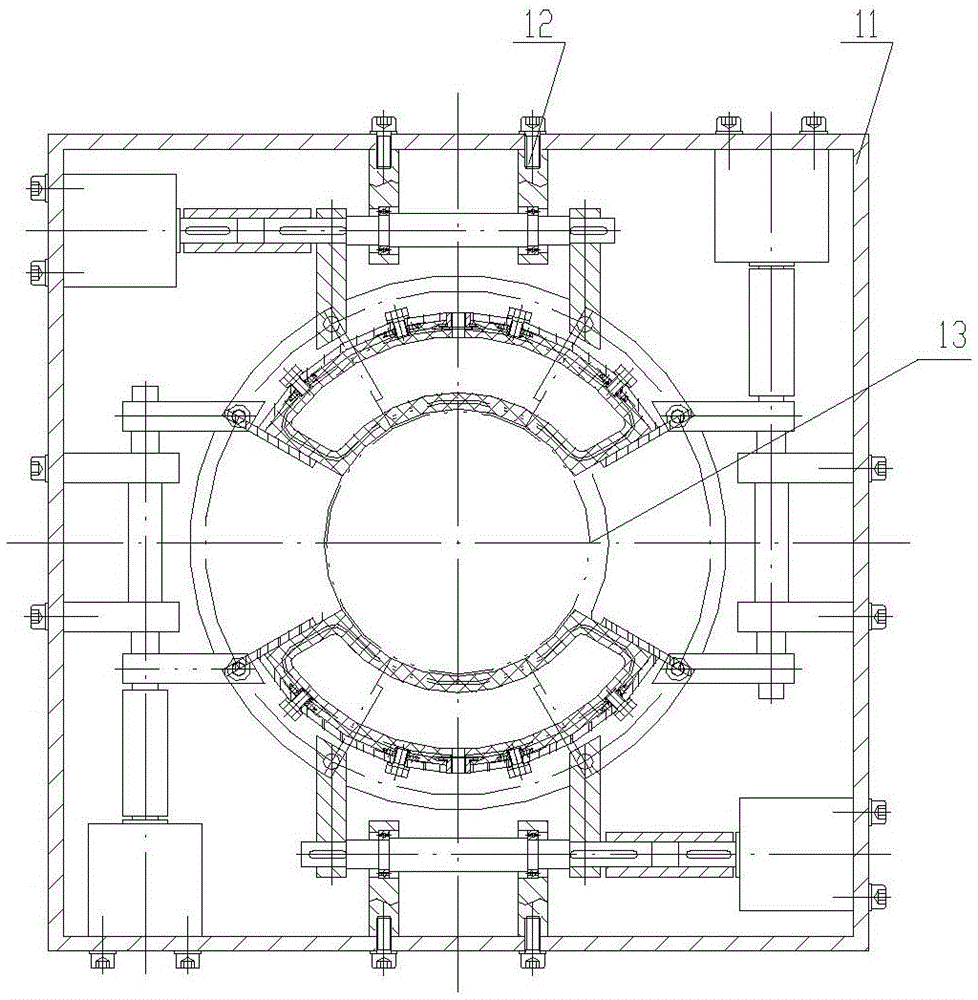

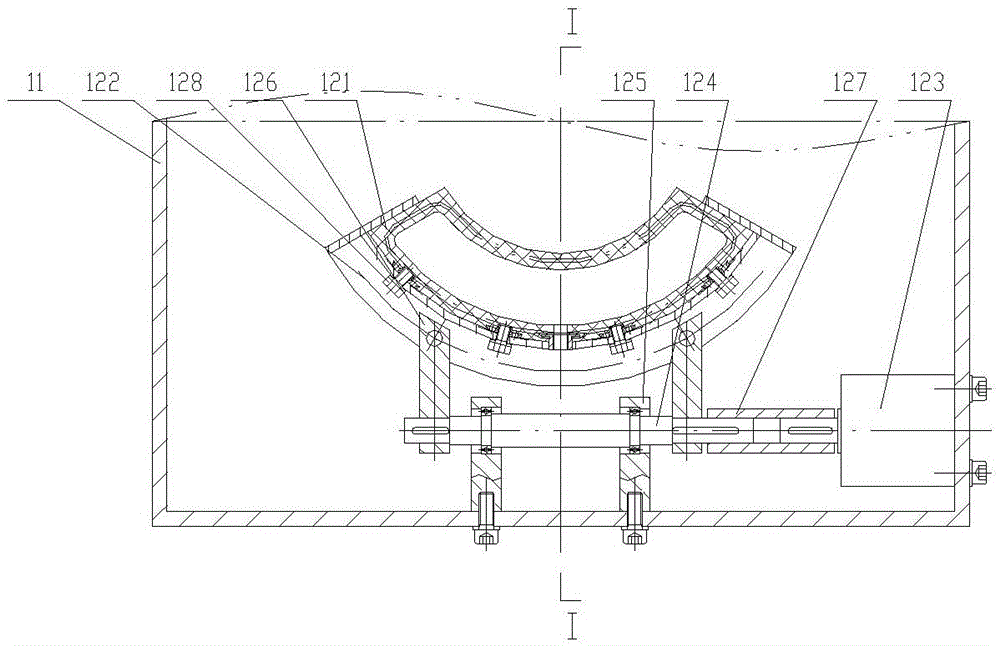

[0045] The present invention as Figure 1-15 As shown, it includes a cylinder body 11 and several groups of mud scraping assemblies 12, and several groups of the mud scraping assemblies 12 are arranged on the inner wall of the cylinder body 11,

[0046] The mud scraping assembly 12 includes an inflatable mud scraping flap 121, a steel ring 122, a swing cylinder 123, a rotating shaft 124, a fixed seat 125, a swing rod 126 and an air source,

[0047] The inflatable mud scraper 121 is arc-shaped and is used to cover the drill pipe 13. The inflatable mud scraper 121 is fixedly connected to the steel ring 122, and the air hole 1211 is provided on the inflatable mud scraper 121. And the drill pipe compensation mechanism, the air source is connected to the air hole 1211; so that the degree of fit between the inflatable mud scraping flap and the drill pipe 13 (that is, the achieved mud scraping effect) is adjusted by the size of the air pressure.

[0048] The swing cylinder 123 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com