Plant cultivation device

a cultivation device and plant technology, applied in the direction of self-acting watering devices, loading/unloading, agriculture gas emission reduction, etc., can solve the problems of troublesome work involved in carrying the culture medium unit or the empty unit, reducing the cultivation efficiency, and reducing the working efficiency of transporting. , the time of transporting the empty unit in order to obtain the culture medium unit is shortened, and the working efficiency of transporting is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

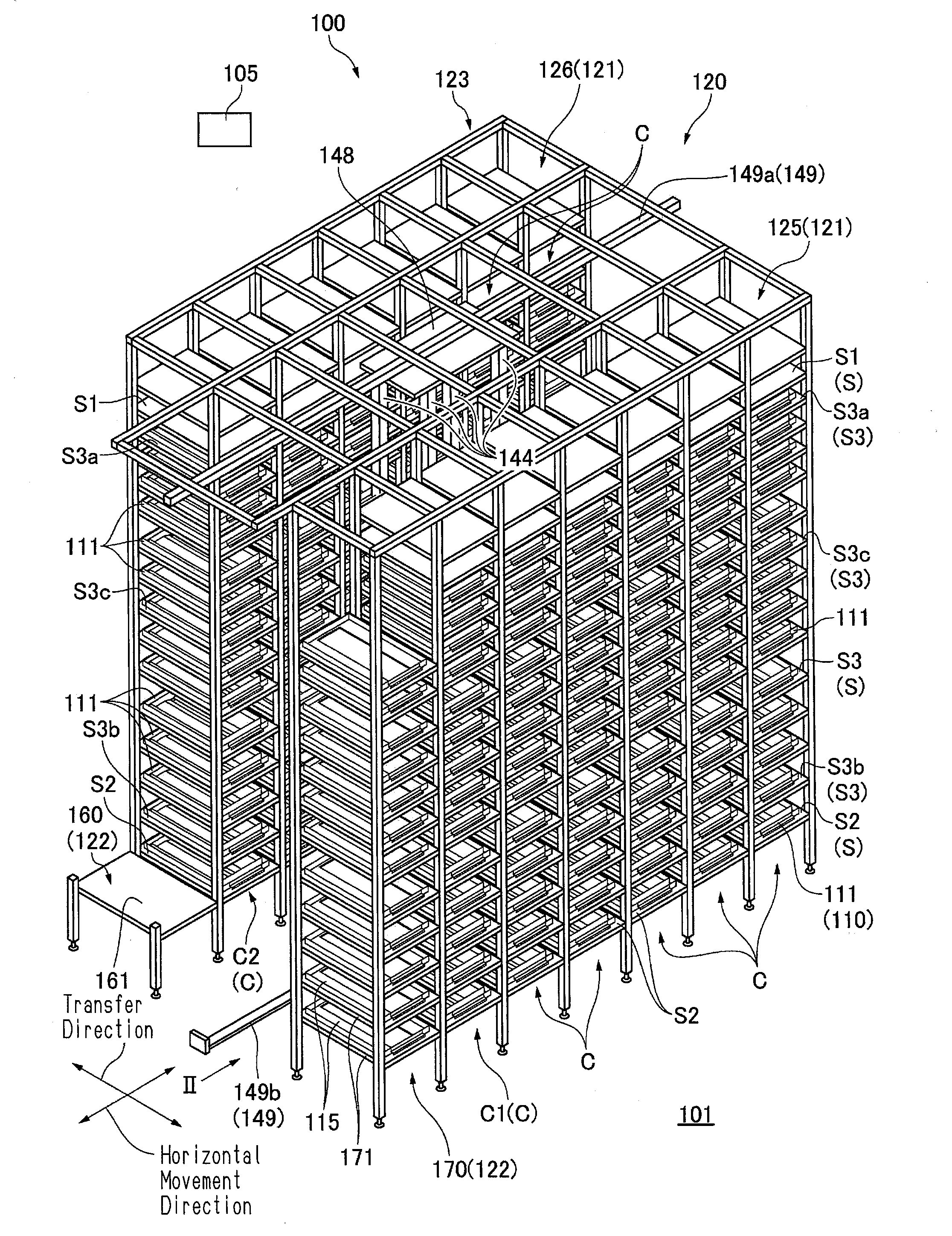

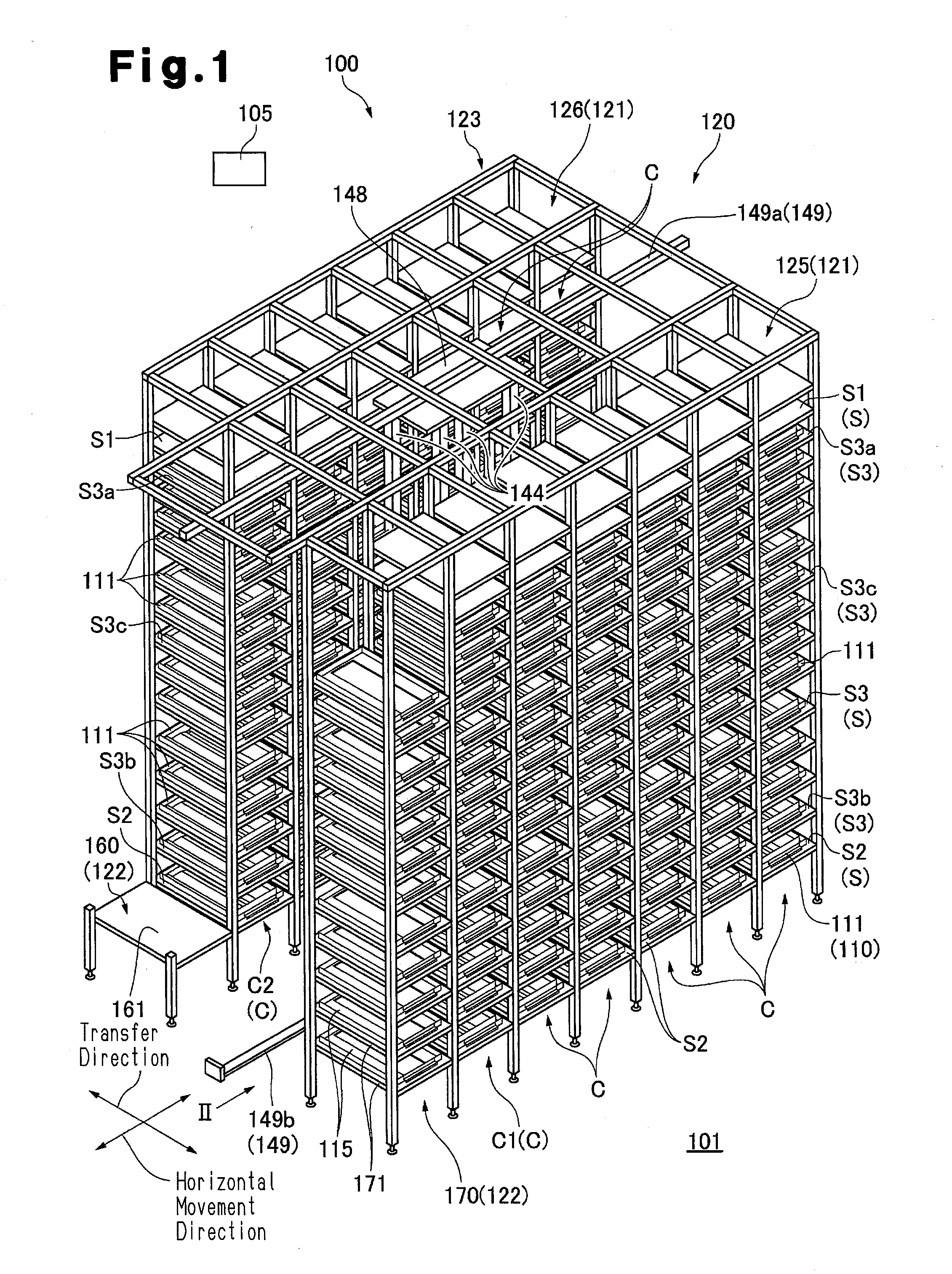

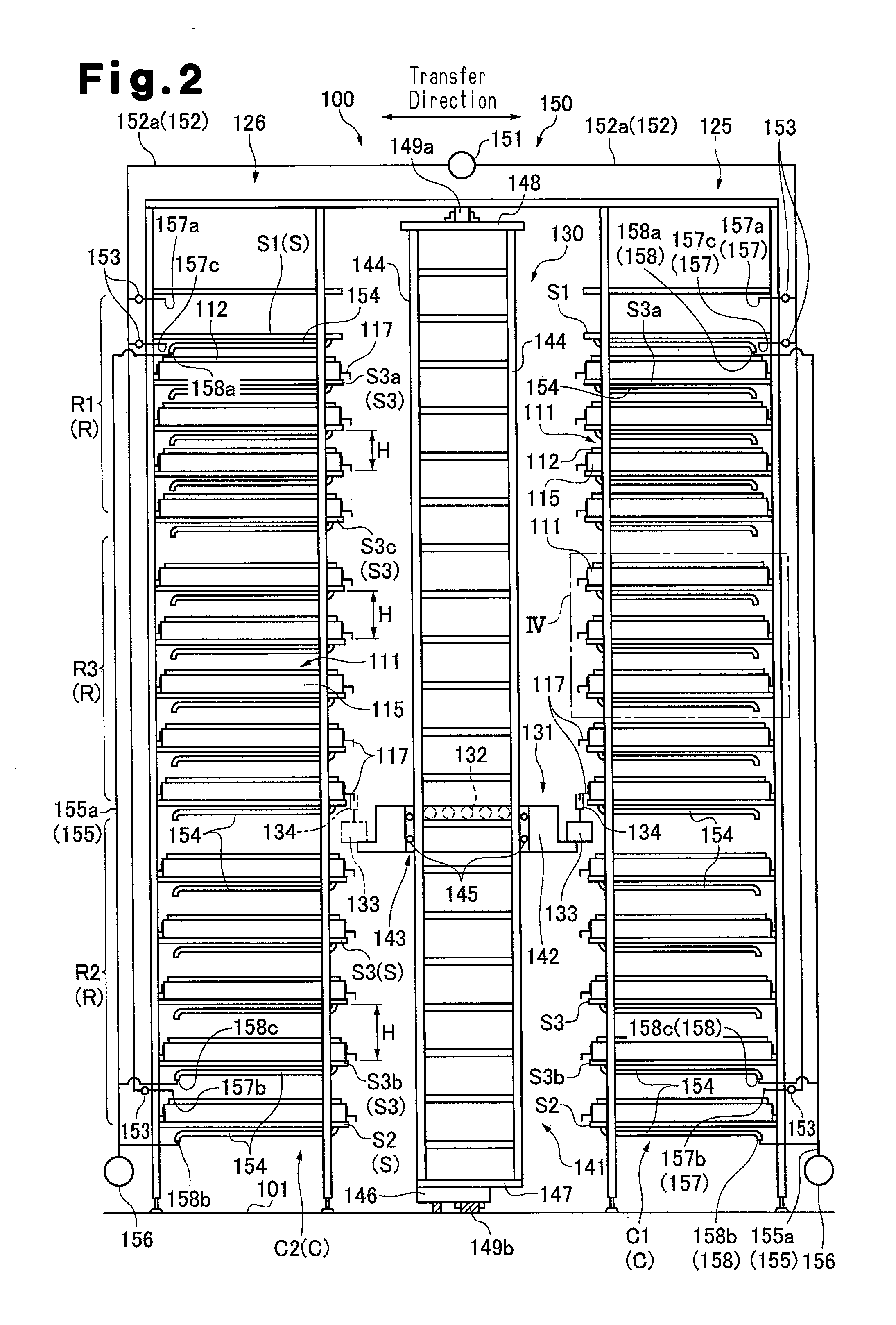

[0046]A plant cultivation device of the present invention includes: a plurality of cultivation units capable of accommodating plants to be cultivated; a rack unit including a plurality of cultivation racks, the cultivation racks storing the cultivation units as culture medium units, the cultivation units accommodating the plants; and a conveying device that moves on a moving pathway, the conveying device transporting the culture medium units, the conveying device carrying the culture medium units in or out of the cultivation racks. Further, a predetermined number of the cultivation racks are arranged in a vertical direction in a multistage fashion to form a single cultivation rack row. The rack unit includes a cultivation storage and a work station. The cultivation storage includes a predetermined number, which is one or a greater number, of cultivation rack rows. The predetermined number is one or a greater number. The work station includes a stock section, the stock station storin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com