Divergent cold light source vertical microalgae culture photoreactor

A technology for photoreactor and microalgae cultivation, which is applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc. There are problems such as not being utilized, and the quality cannot be stabilized, so as to achieve the effects of reducing adherent growth, eliminating blind spots of light, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

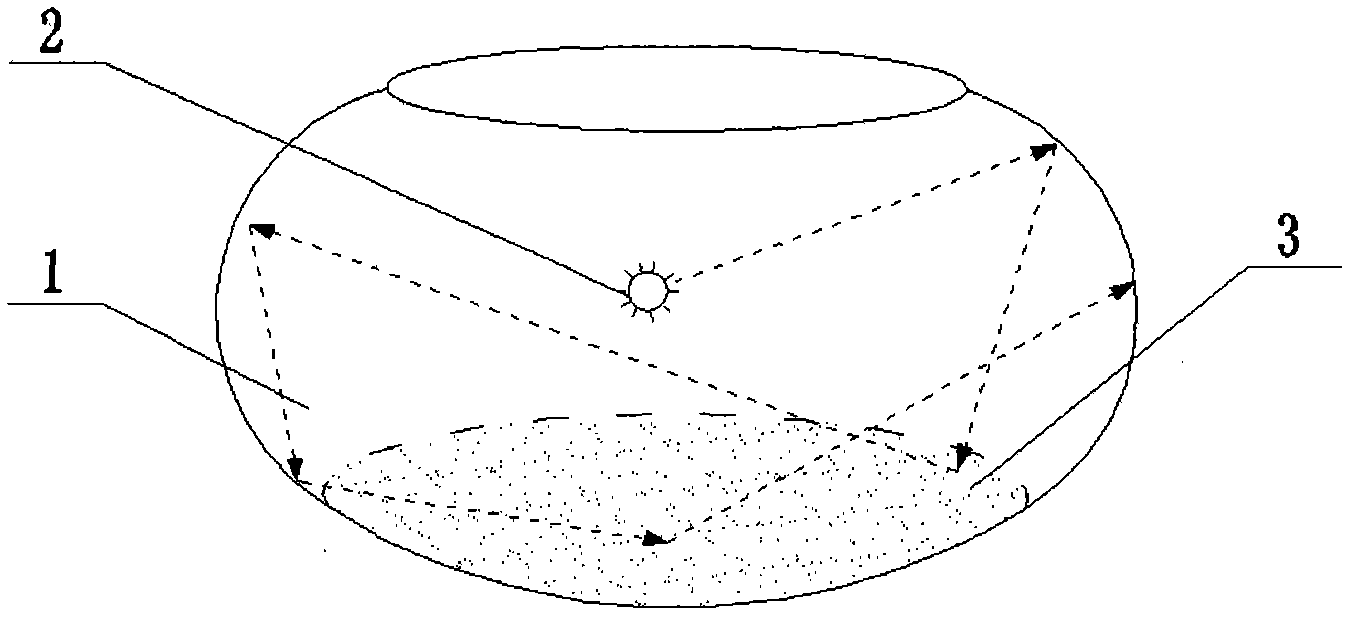

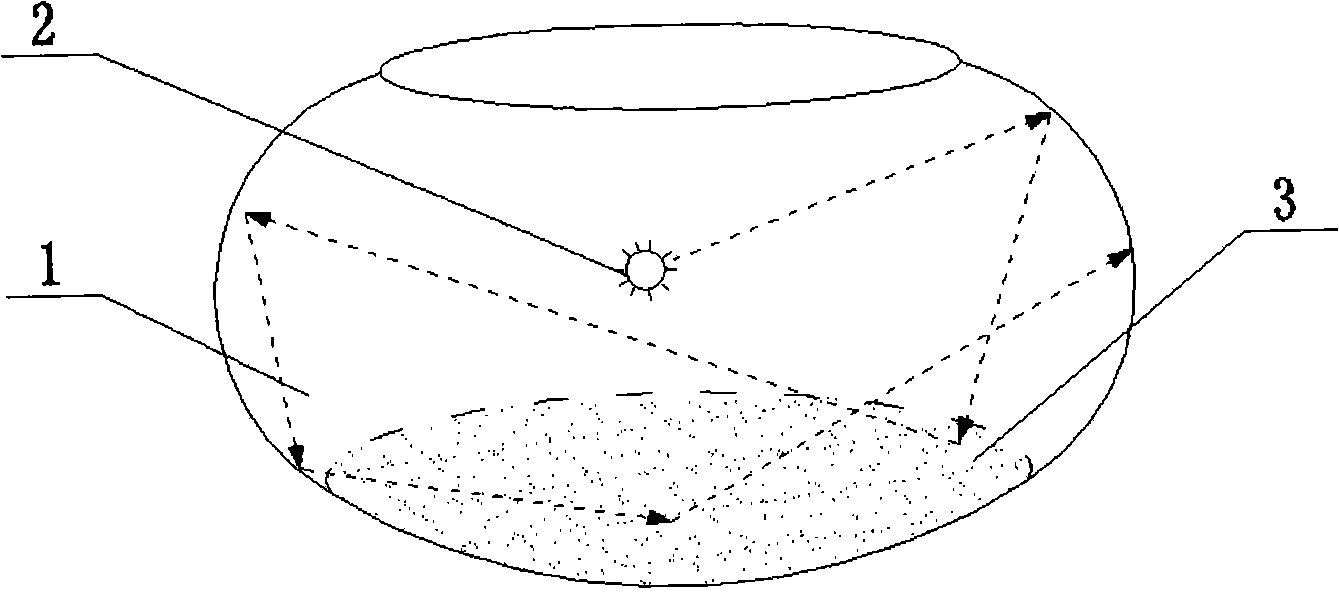

[0015] Such as figure 1 , figure 2 Shown:

[0016] 1 is a photobioreactor, 2 is a spherical light source, and 3 is a reflective material.

[0017] Attached below Figure 1-Figure 2 Embodiments of the present invention are described:

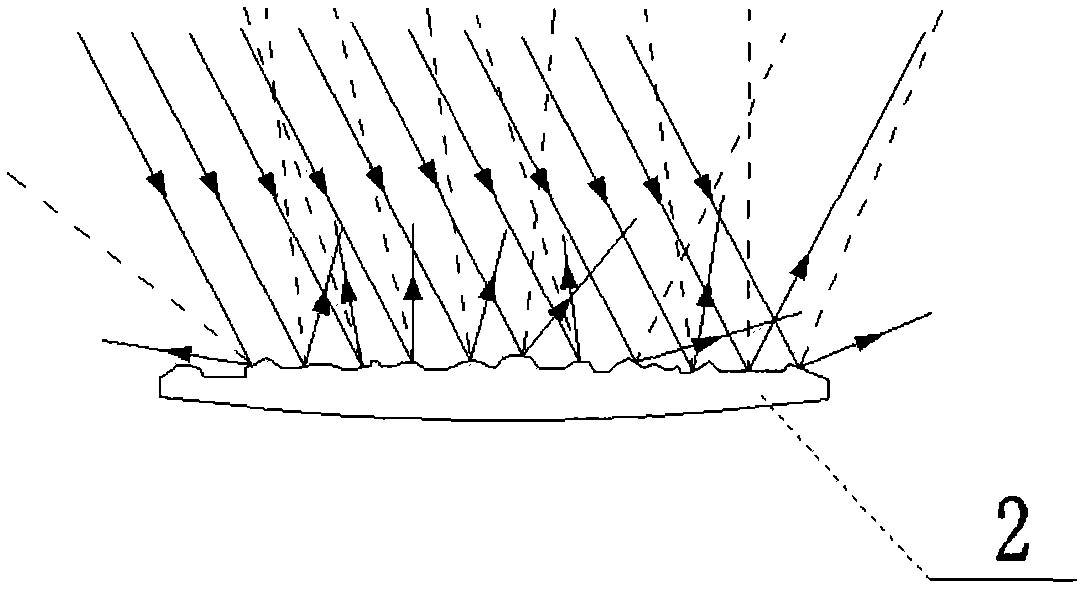

[0018] Such as figure 1 , figure 2 As shown, the photobioreactor 1 is an ellipsoidal container of transparent light-transmitting material, and the spherical light source 2 is a power-driven electric storage light source that emits light evenly around it. Set the trajectory movement, 3 is reflective material, which is laid on the bottom of the reactor to form a new light source and improve the utilization rate of light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com