Stereoscopic plant cultivation system

A three-dimensional cultivation and plant technology, applied in cultivation, planting beds, soilless cultivation and other directions, can solve the problems of difference in light amount, inability to control the amount of sunlight exposure, data accuracy and reliability reduction, etc., to save manpower and material resources, The effect of reducing the difference in sunlight exposure and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

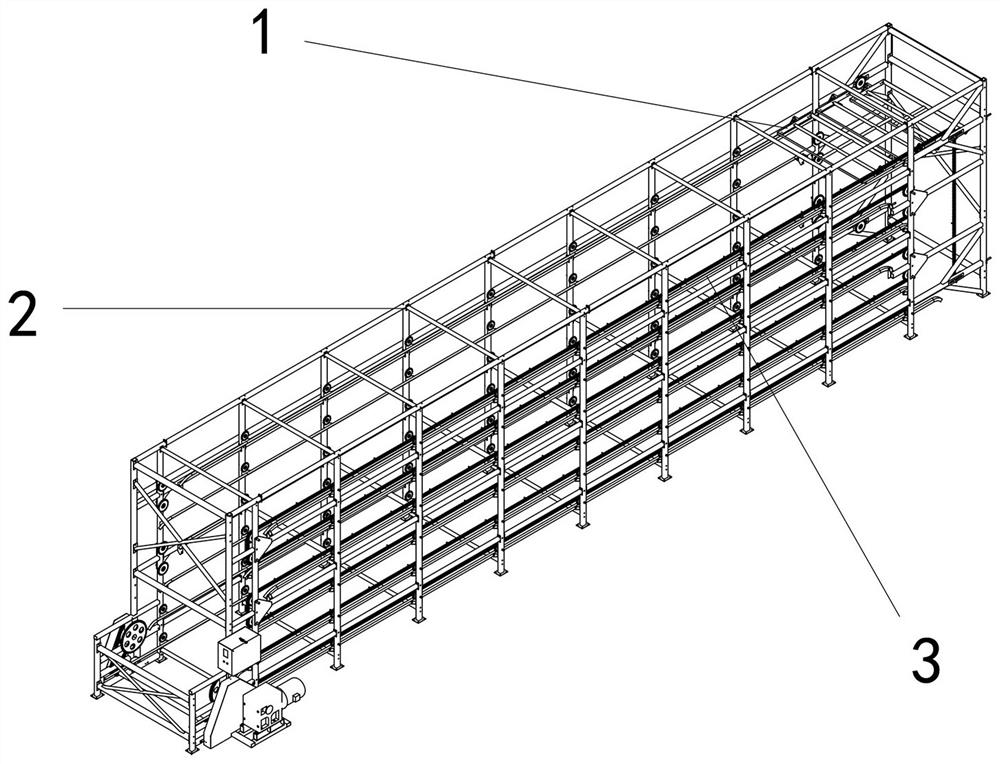

[0048] Embodiment 1: In this embodiment, a carrier tray 1 capable of cultivating plants in multiple different positions is provided to move continuously and circularly on the three-dimensional transport transfer frame 2 to reduce the sunlight exposure of the plants in each carrier tray 1 Three-dimensional cultivation system for plants of different degrees, the system mainly includes a carrying tray 1 for carrying the substrate of the plants and cultivating plants, and for realizing the continuous circular movement of the carrying tray 1 at different levels and heights. Three-dimensional conveying transfer frame 2 two parts.

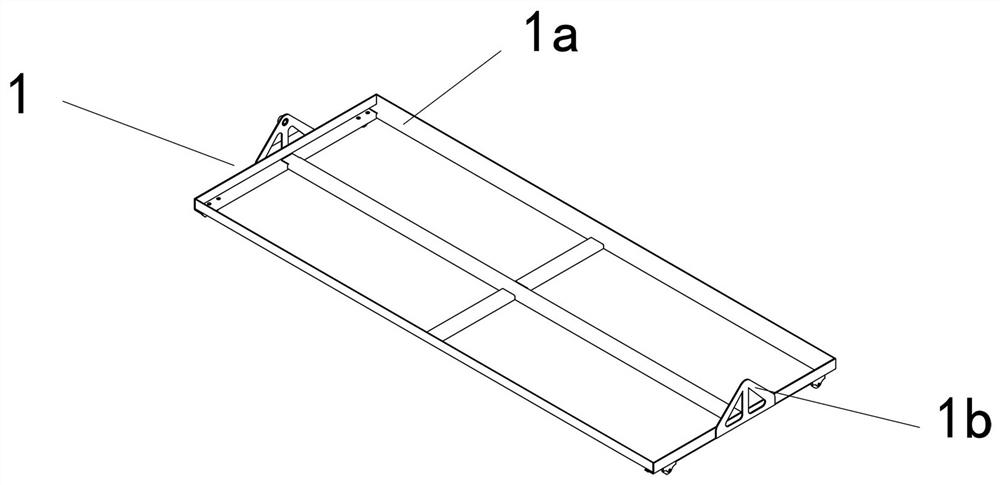

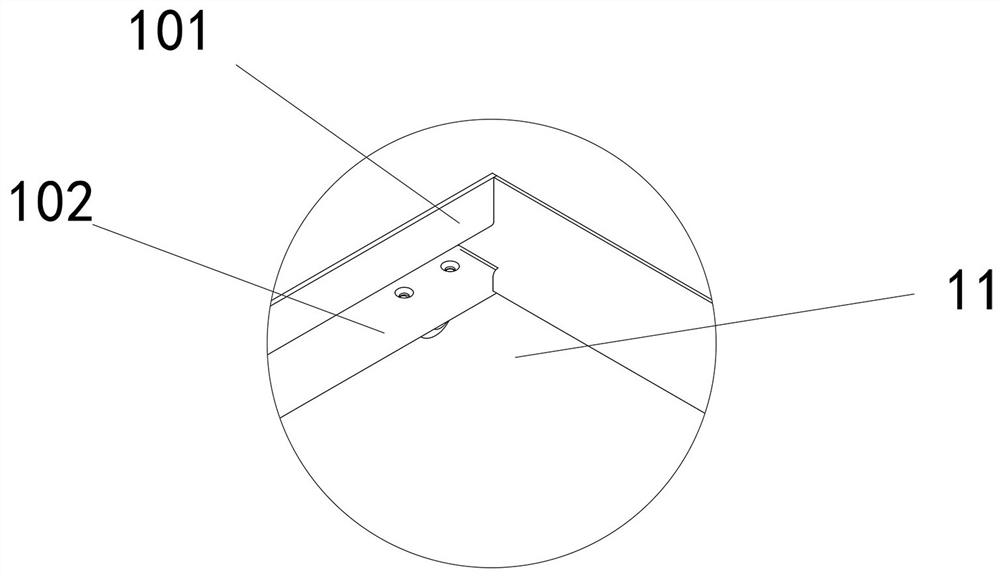

[0049] As for the carrying tray 1, specifically, the carrying tray 1 includes a tray main body, which is connected end-to-end with steel materials with an L-shaped cross-section and connected by welding to form an overall mouth-shaped Main frame part 1a. Since the L-shaped steel used as the raw material includes a portion extending in the horizontal dire...

Embodiment 2

[0057] Embodiment 2: On the basis of the plant three-dimensional cultivation system described in Embodiment 1, considering that when moving the position of the carrying tray 1, it is necessary to continuously change the position of the carrying tray 1 in the horizontal direction and the vertical direction, so in the horizontal Between the transfer unit 5 and the vertical transfer unit 4 should be provided a transition reversing device 6 that can realize a smooth transition of the carrying tray 1 between different movement modes in the two parts of the unit. Specifically, a conveying chain 8 formed by connecting several chain link units 8a in an hinged manner can be used as a component for installing the carrying tray 1 to drive it to move. Since the hinge center of the connection between the two link units 8a on the conveyor chain 8 is relatively stable relative to the single link unit 8a, if the carrier tray 1 is installed at this place, the degree of influence on the movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com