Bilateral and vertical inter-plant weeding machine capable of automatically avoiding obstacles

A technology of automatic obstacle avoidance and weeding machine, which is applied in the fields of soil preparation machinery, non-electric variable control, agricultural machinery and implements to achieve the effect of reducing cost, improving intelligence and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

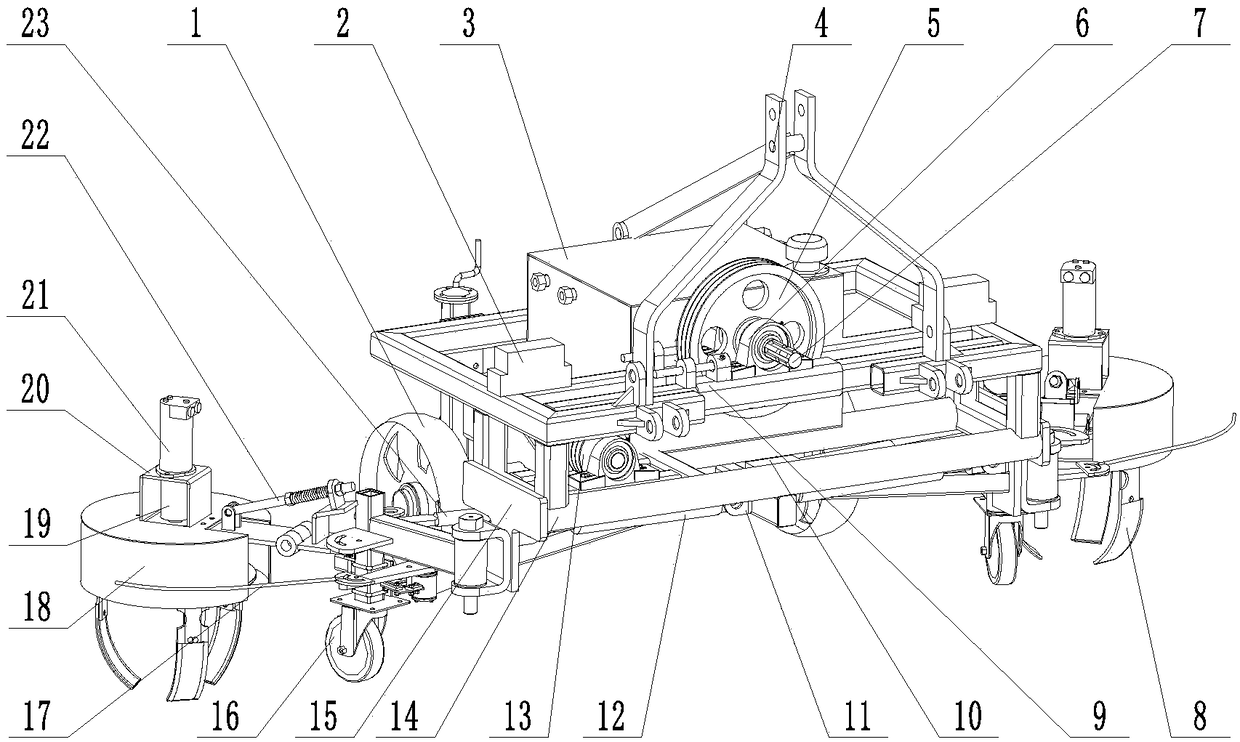

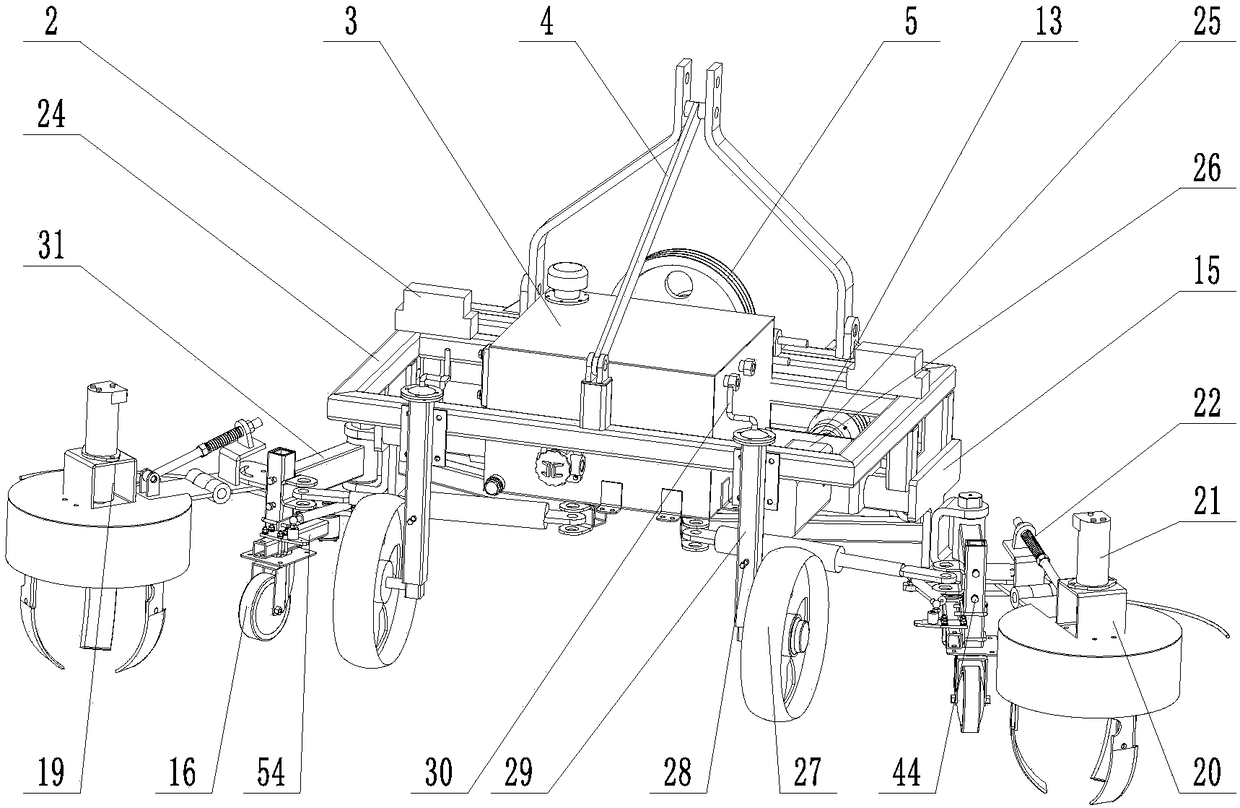

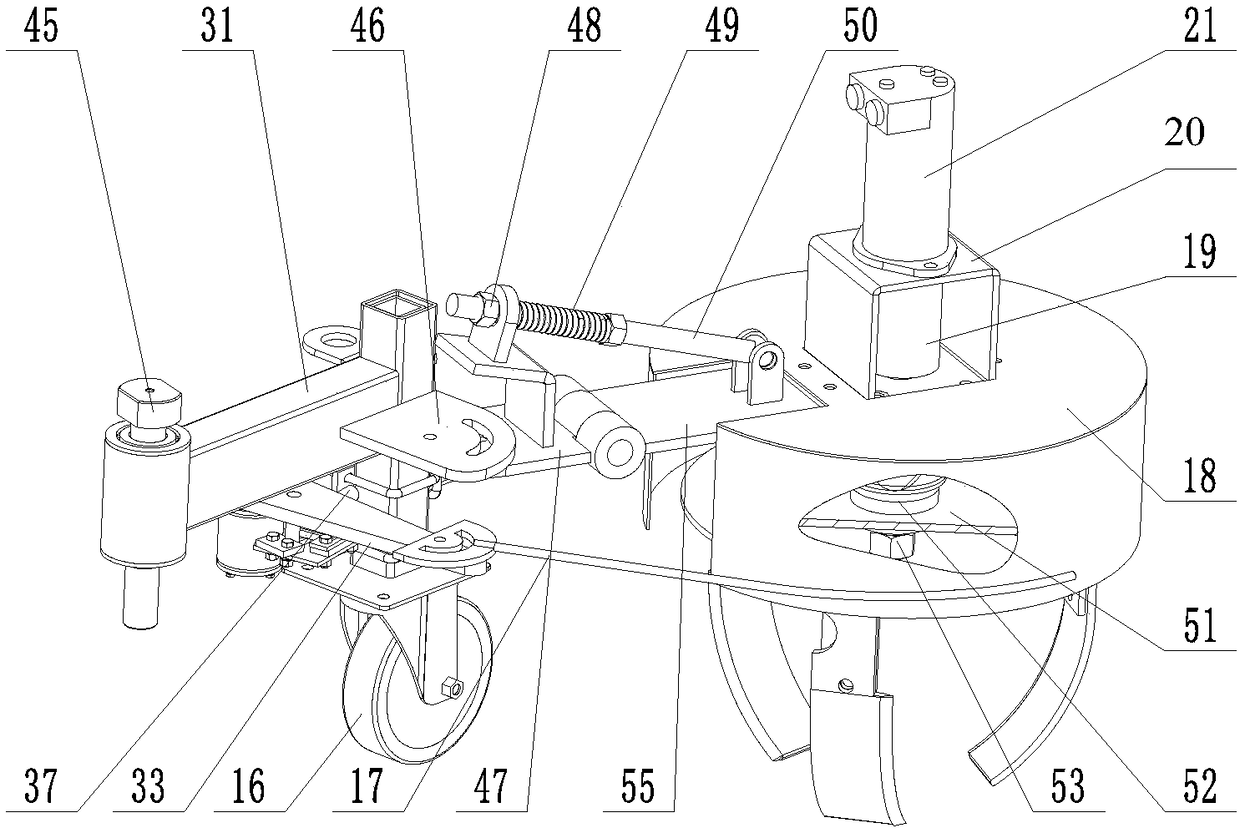

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0042] The present invention is based on the following idea: the whole machine is suspended behind the tractor by using a three-point suspension unit, and the tractor PTO is used to provide power for an independent hydraulic system to drive each hydraulic cylinder and each hydraulic motor to perform operations; The row width of the whole machine is adjustable, and the hydraulic cylinder is used as the driving force of the row width adjustment unit; the weeding unit is separated on both sides to realize the bilateral operation of the weeding process. Each side uses a set of hydraulic circuits that do not interfere with each other, and can work independently in time. Improve the working efficiency of the whole machine; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com