Feed-type vibratory feeding method and feed-type vibratory feeding mechanism

A feeding method and feeding technology, which is applied in the field of feeding vibration feeding and its feeding mechanism, can solve the problems of unsuitable plate feeding dosage, unqualified products, waste materials, etc., and achieve significant technological progress, high yield, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

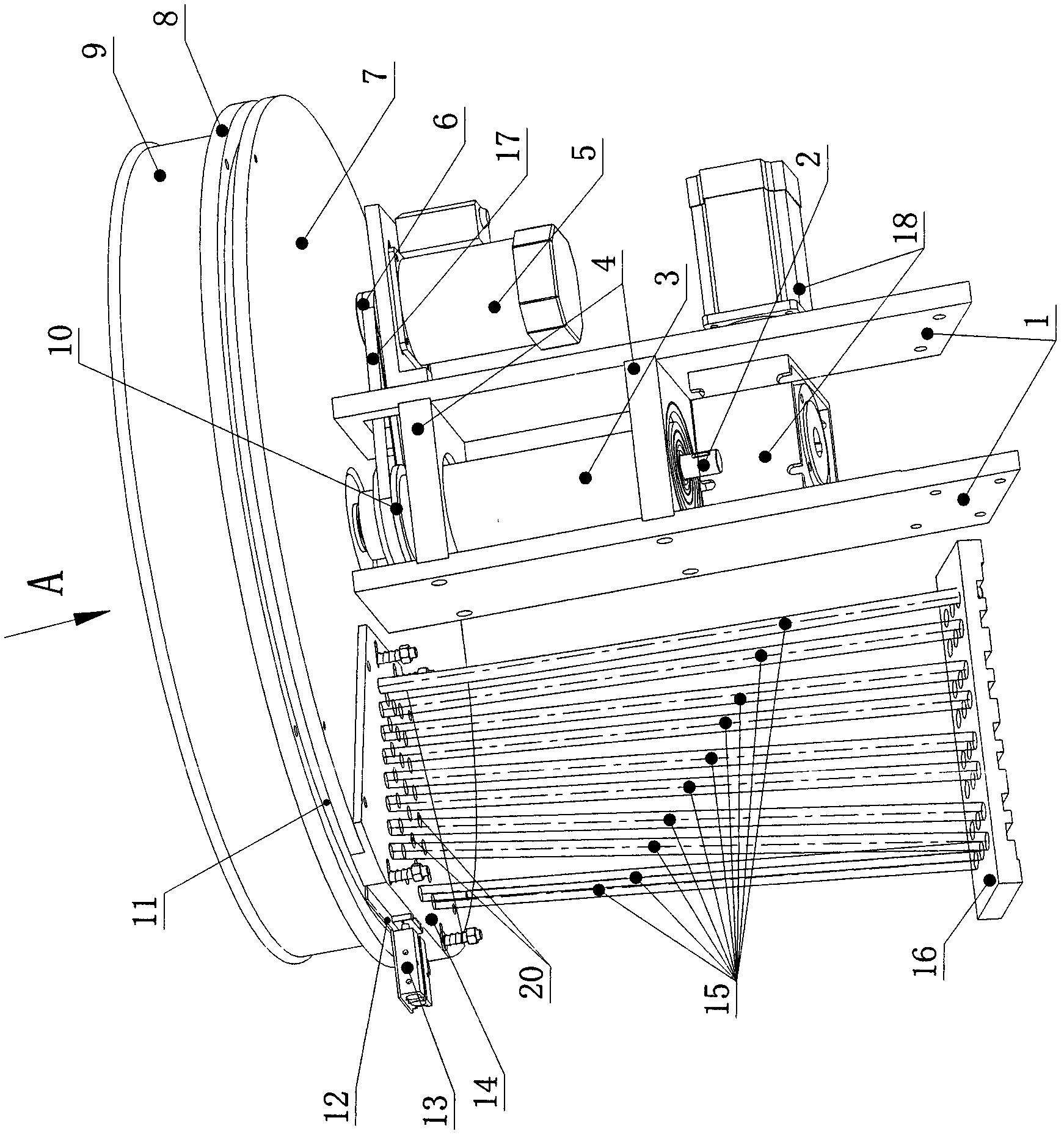

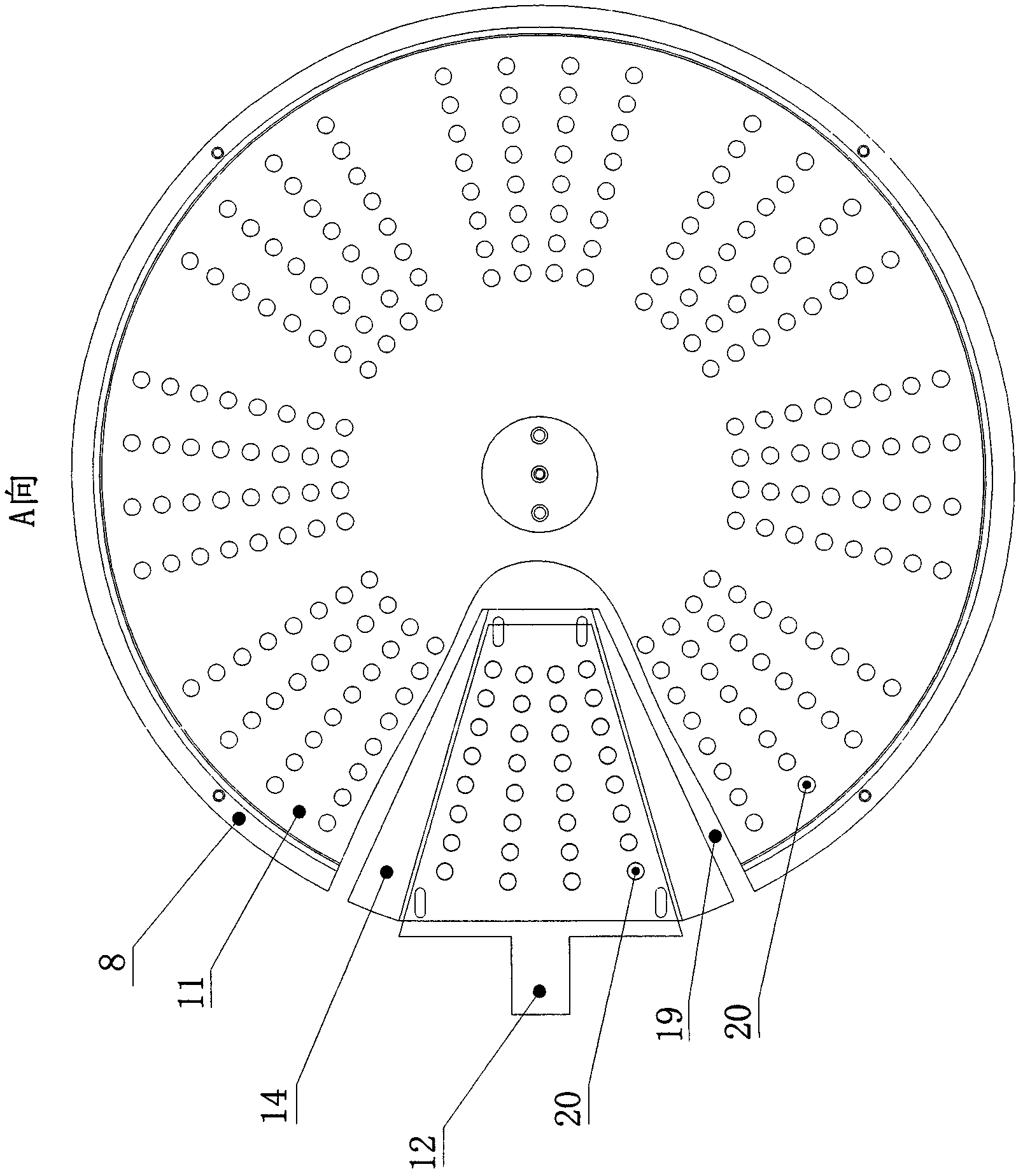

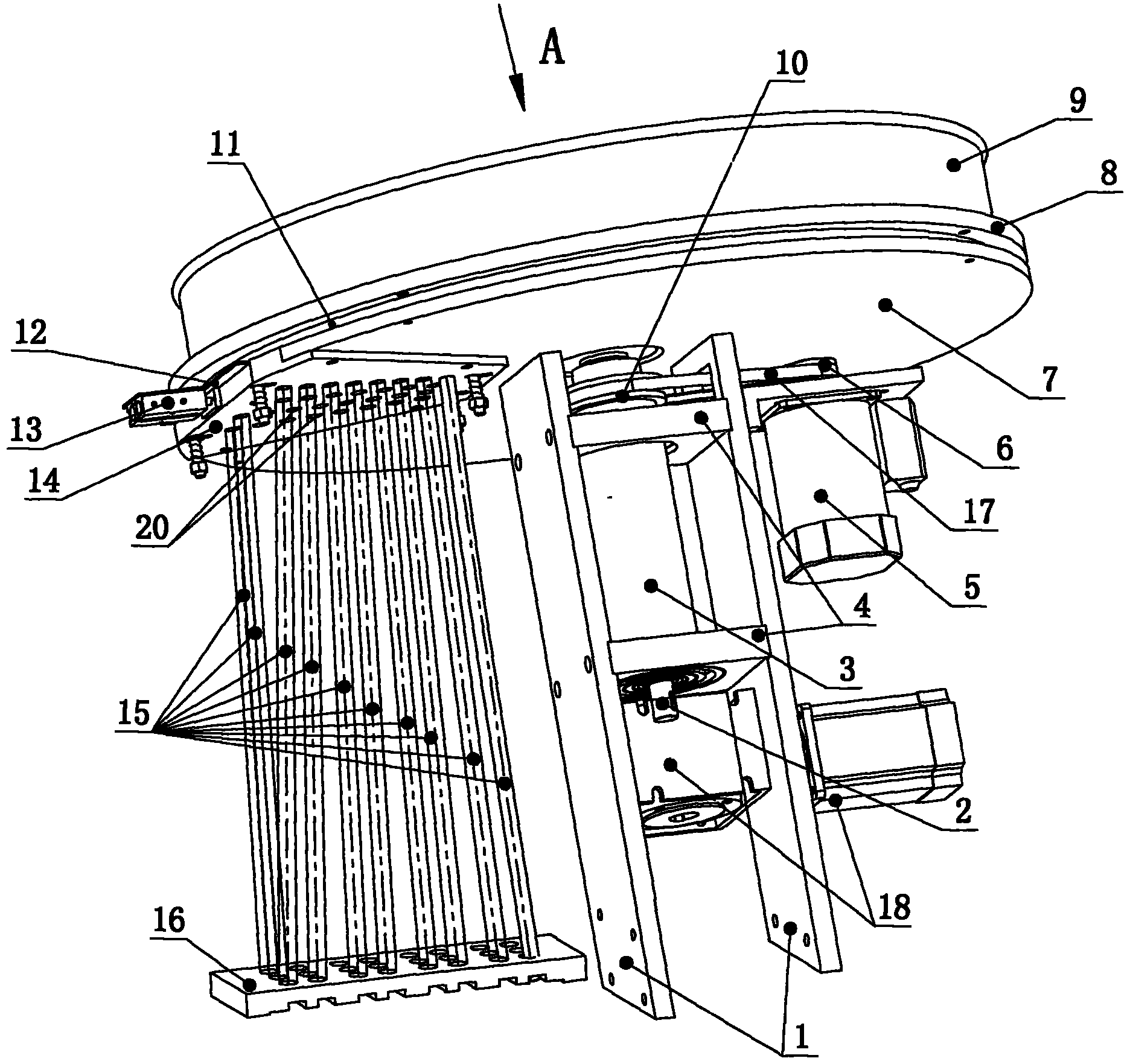

[0010] refer to figure 1 , figure 2 It can be seen that the feed-type vibration feeding method applied to the automatic blister packaging machine (especially the aluminum-aluminum packaging of special-shaped sheets) of the present invention is: first, the material is poured into the vibration fixed plate of the vibration plate, and on the vibration fixed plate There is a gap, the vibrating plate is driven to rotate by the transmission device, and the vibrating device vibrates, and the material will (slowly) enter the hole of the vibrating fixed plate (each material enters a hole correspondingly); when the vibrating fixed plate Rotate a group of holes to the top of the blanking switch plate at the gap of the vibrating fixed plate, and until they correspond to the holes on the blanking switch plate one by one, the blanking cylinder works to move the blanking switch plate (quickly) to Pull it out (and return it quickly), so that the material in the hole on the vibrating fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com