Pressure feed type high-pressure dense-phase pneumatic conveying device and pneumatic conveying method

A pneumatic conveying and pressure-feeding technology, applied in the field of powder material supply devices, can solve the problems of overall flow influence, low coal powder concentration, prone to failure, etc., to improve wear resistance and service life, gas-solid impact wear Reduce and avoid the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

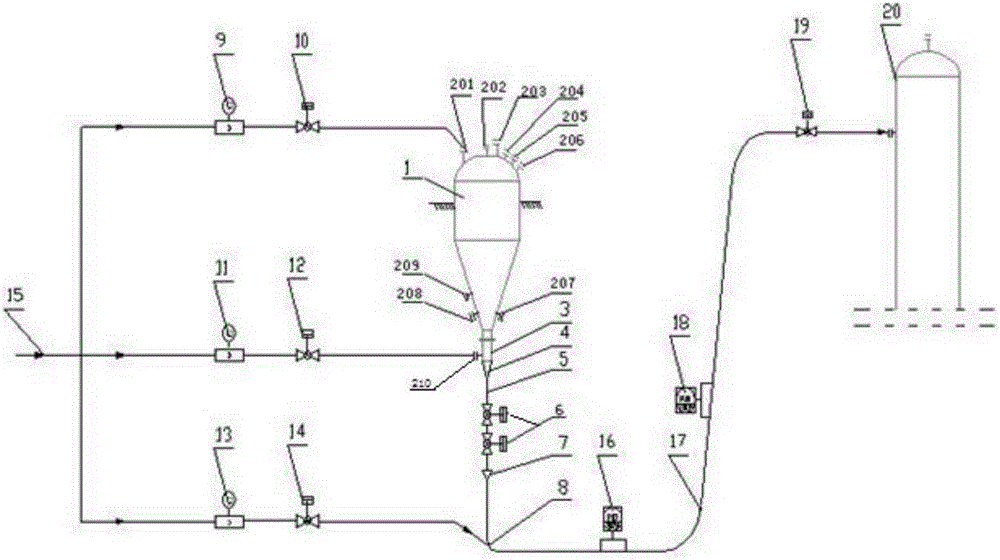

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, a pressure-feeding high-pressure dense-phase pneumatic conveying device includes a bottom-discharging delivery tank 1, and a pressure charging port 201, a powder inlet 202, Pressure relief port 203 , safety valve port 204 , nitrogen replacement gas pressure charging port 205 , nitrogen replacement gas pressure relief port 206 . The lower part of the main body of the delivery tank 1 is a cone bucket. In order to ensure the free downward overall flow of the powder in the delivery tank, the included angle of the busbar of the cone bucket is set at 15-45 degrees. A gas sampling port 207, a temperature measuring port 208 and a pressure measuring port 209 are provided on the side wall of the cone bucket.

[0025] The outlet of the lower cone bucket of the delivery tank 1 is connected to the vertically arranged first straight pipe section 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com