Intermittent feeding type feed mixing and crushing device for organic agriculture

An agricultural and feeding technology, applied in feed, mixer with rotary stirring device, application, etc., can solve the problems of high labor intensity, low degree of automation, heavy equipment burden, etc., and achieve the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

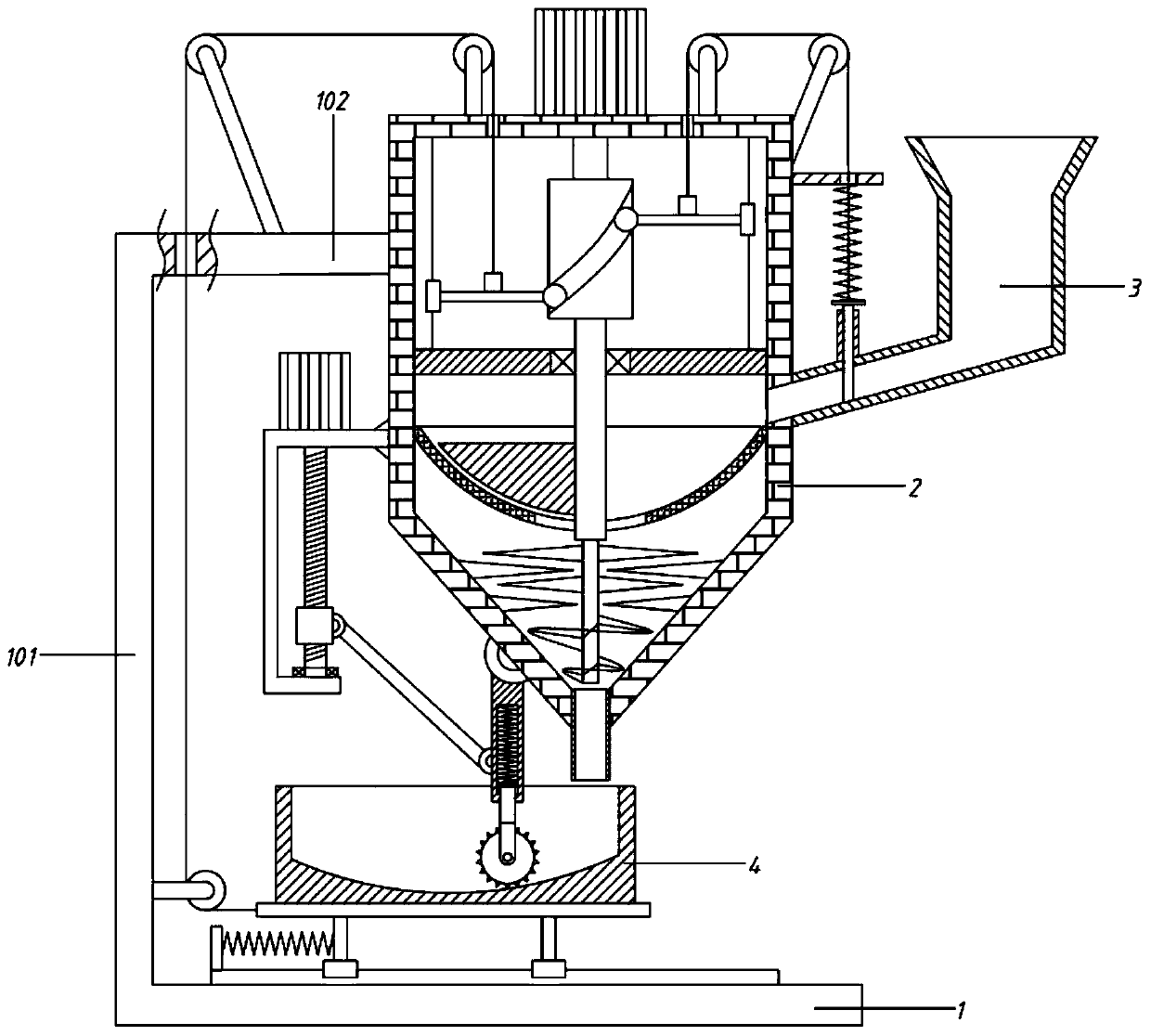

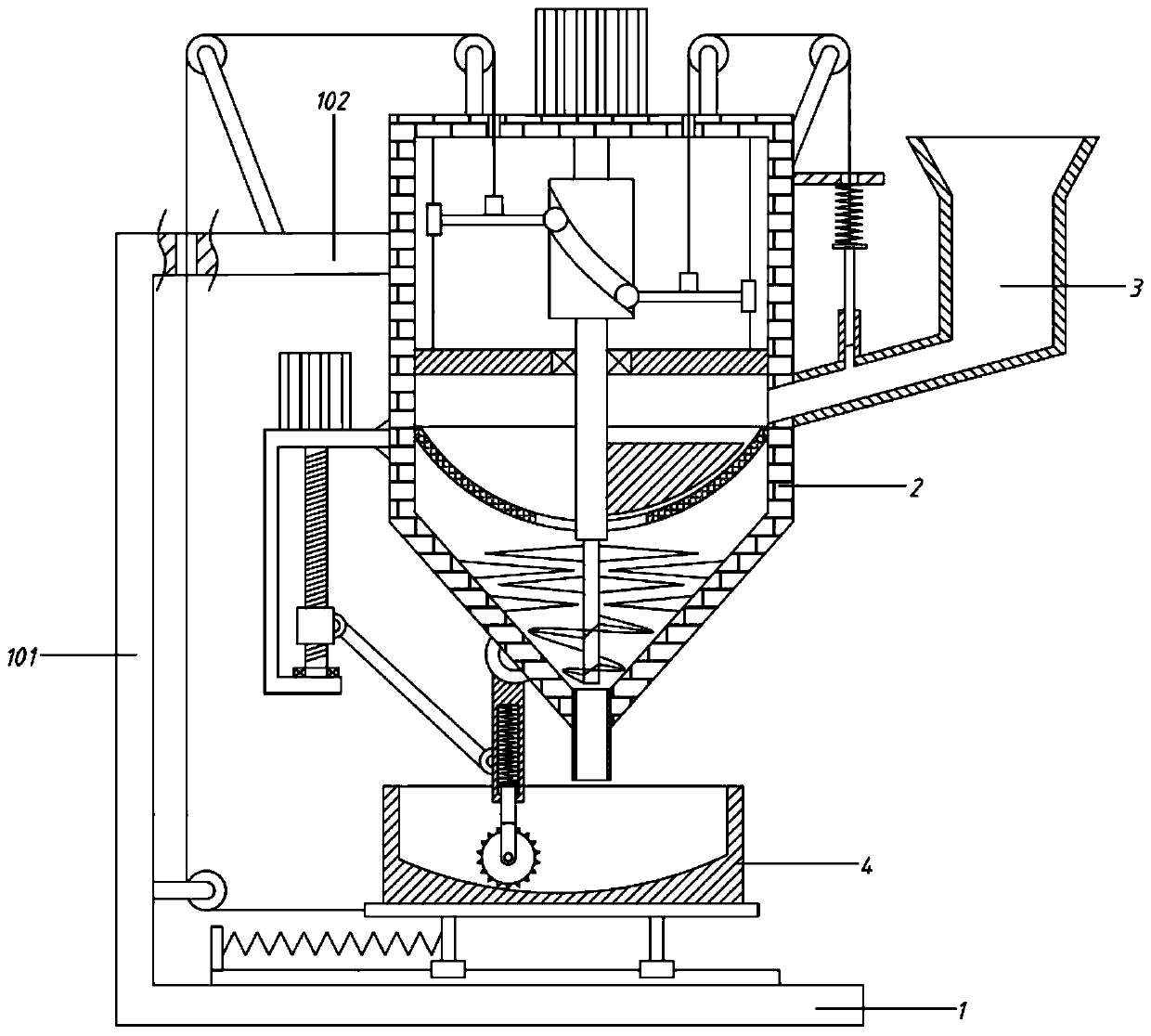

[0055] An intermittent feeding type feed mixing equipment for organic agriculture, comprising a housing 2 and a feeding hopper 3;

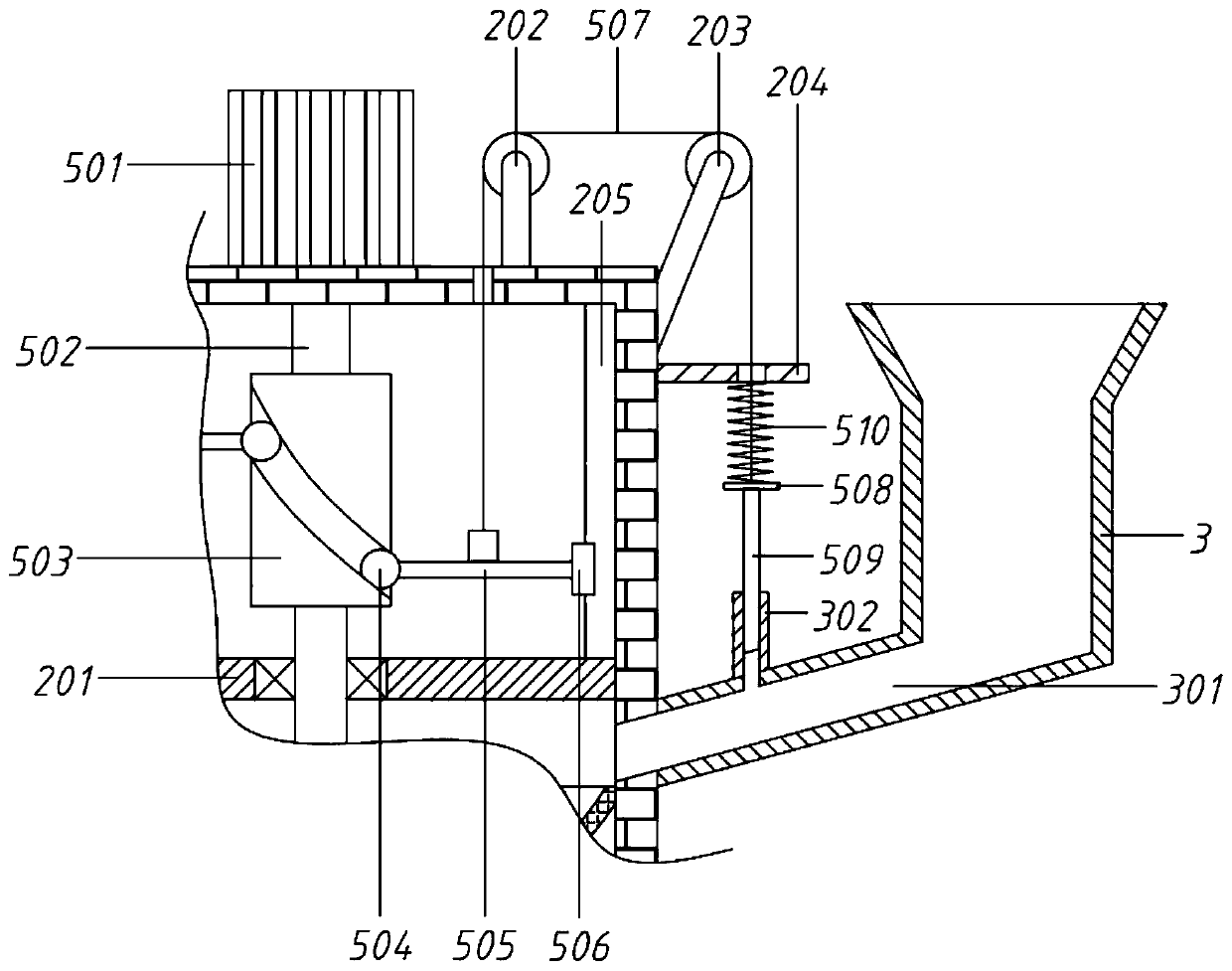

[0056] A partition 201 is fixed in the shell 2, which divides the inner cavity of the shell 2 into a cam cavity and a crushing cavity; the crushing cavity is provided with a mixing component;

[0057] The feed hopper 3 is arranged on the right side of the housing 2, and the bottom of the feed hopper 3 communicates with the upper part of the crushing chamber through the guide tube 301 inclined downward to the left; It communicates with the material guide pipe 301, the baffle plate 509 is plugged into the baffle cover 302, the top of the baffle plate 509 protrudes from the baffle cover 302 and is connected with a pull plate 508; the side wall of the cam chamber is fixedly connected with a support plate above the pull plate 508 204, a No. 1 spring 510 is connected between the support plate 204 and the pull plate 508;

[0058] There is a No. 1 servo ...

Embodiment 2

[0062] An intermittent feeding type feed mixing equipment for organic agriculture, comprising a housing 2 and a feeding hopper 3;

[0063] A partition 201 is fixed in the shell 2, which divides the inner cavity of the shell 2 into a cam cavity and a crushing cavity; the crushing cavity is provided with a mixing component;

[0064] The feed hopper 3 is arranged on the right side of the housing 2, and the bottom of the feed hopper 3 communicates with the upper part of the crushing chamber through the guide tube 301 inclined downward to the left; It communicates with the material guide pipe 301, the baffle plate 509 is plugged into the baffle cover 302, the top of the baffle plate 509 protrudes from the baffle cover 302 and is connected with a pull plate 508; the side wall of the cam chamber is fixedly connected with a support plate above the pull plate 508 204, a No. 1 spring 510 is connected between the support plate 204 and the pull plate 508;

[0065] There is a No. 1 servo ...

Embodiment 3

[0071] An intermittent feeding type feed mixing equipment for organic agriculture, comprising a housing 2 and a feeding hopper 3;

[0072] A partition 201 is fixed in the shell 2, which divides the inner cavity of the shell 2 into a cam cavity and a crushing cavity; the crushing cavity is provided with a mixing component;

[0073] The feed hopper 3 is arranged on the right side of the housing 2, and the bottom of the feed hopper 3 communicates with the upper part of the crushing chamber through the guide tube 301 inclined downward to the left; It communicates with the material guide pipe 301, the baffle plate 509 is plugged into the baffle cover 302, the top of the baffle plate 509 protrudes from the baffle cover 302 and is connected with a pull plate 508; the side wall of the cam chamber is fixedly connected with a support plate above the pull plate 508 204, a No. 1 spring 510 is connected between the support plate 204 and the pull plate 508;

[0074] There is a No. 1 servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com