Whole-feed type combine harvester with vertical reaper

A combined harvester and full-feeding technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of many restricted conditions for threshing, difficulty in harvesting lodging rice, and unclean threshing.

Inactive Publication Date: 2010-08-25

GUANGXI GUIGANG COMBINE HARVESTER

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

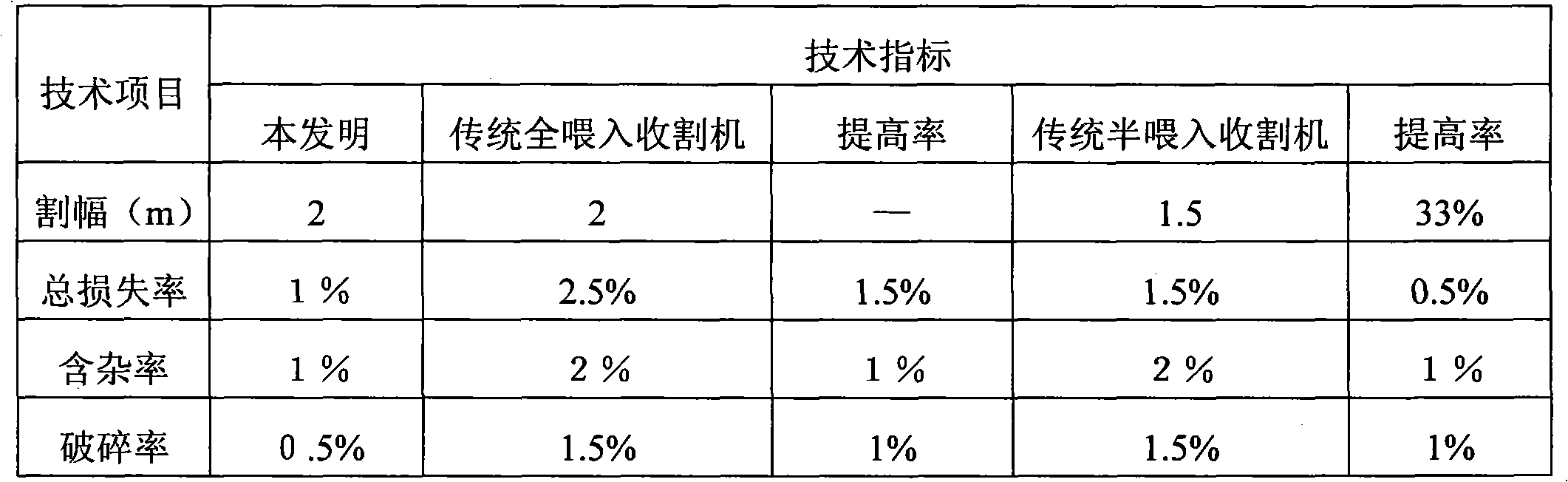

The invention provides a vertical header full-feed combine harvester, absorbing the advantages of full-feed harvesters and half-feed harvesters, and solving the difficulties of traditional full-feed combine harvesters in harvesting lodging rice and threshing. There are many restricted conditions and the problem of unclean threshing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

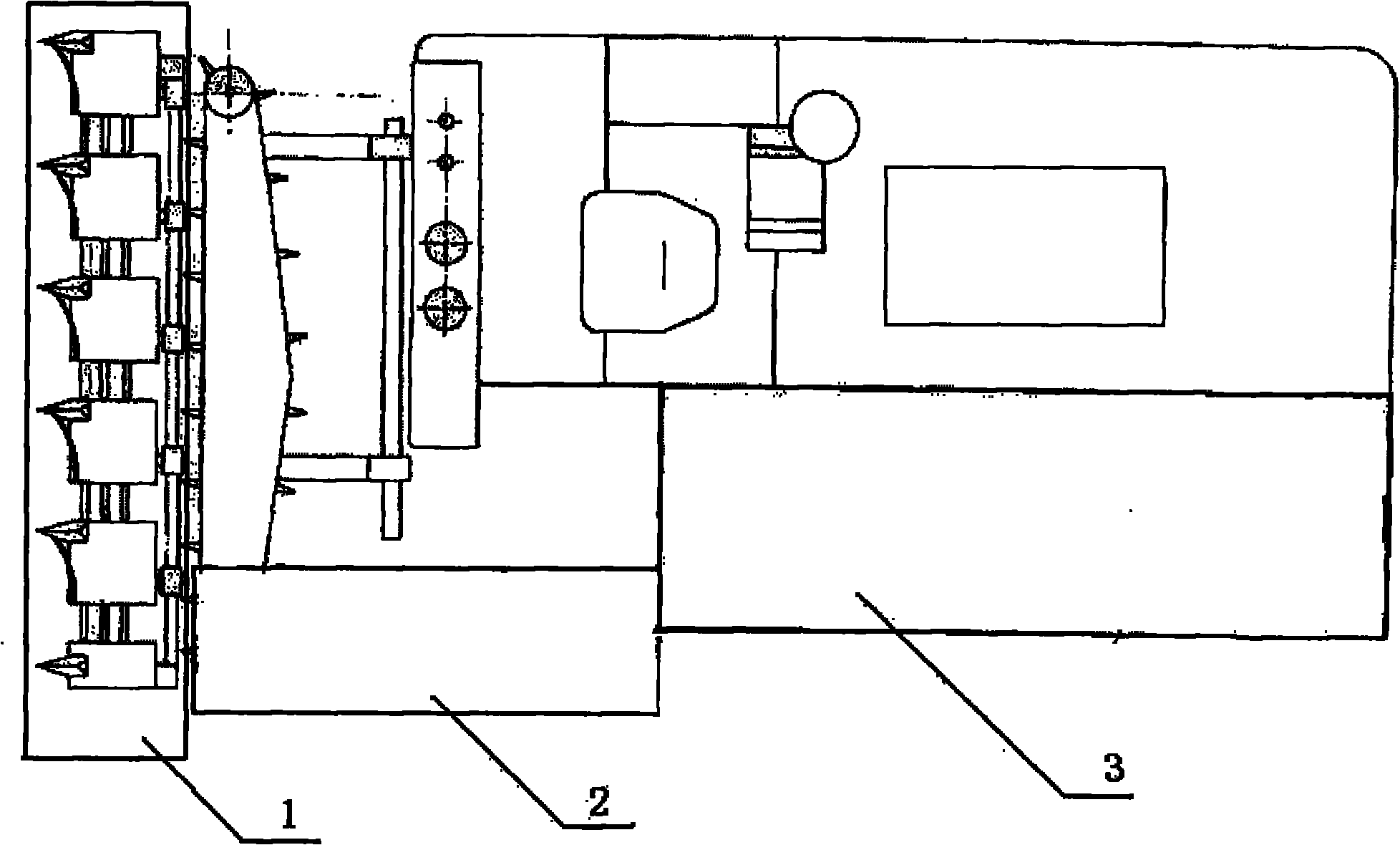

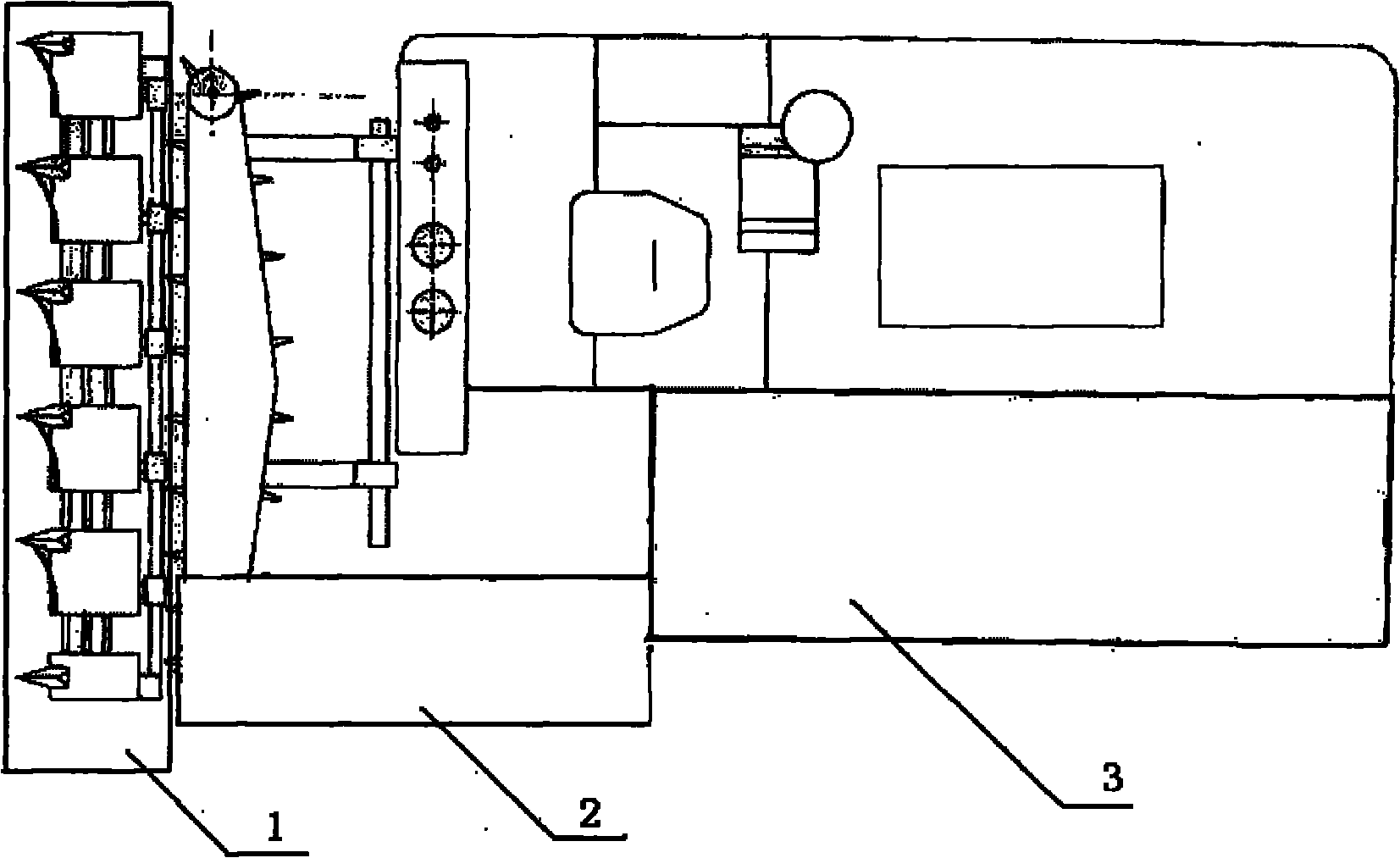

The invention provides a whole-feed type combine harvester with a vertical reaper. The invention is characterized in that the vertical reaper is wider than the reaper of a half feeding type combine harvester; a compulsory clamp turning conveyor is arranged on an ear feeding device which is formed by respectively adding a double teeth clamp chain between the two rows of conveying chains and at a turning; press steel wires are arranged between the upper and lower tooth of the double teeth clamp chain, and the height thereof is lower than the prong height of the double teeth clamp chain; a driving wheel for driving the double teeth clamp chain and a driven wheel of the conveying chains are coaxial. A threshing device uses a design of a longitudinal axial-flow type threshing cylinder, the threshing tooth of the threshing cylinder are in a spiral belt shape revolving a shaft and are fixed on the surface of the cylinder; and the angle of the threshing tooth and the cylinder shaft can be regulated. The invention derives advantages of the whole-feed type harvester and the half feeding type harvester, thereby solving the problem that the traditional whole-feed type combine harvester is hard to harvest lodging rice, has more threshing constraints and the threshing is unclean; and the invention has the advantages of clean threshing, complete separation, low broken rate and less trash content.

Description

technical field The invention relates to a harvester, in particular to an array-in-grain full-feed combine harvester adopting a vertical header. Background technique At present, the combine harvesters on the market are mainly divided into two types: half-feeding type and full-feeding type. Both full-feeding and half-feeding have their own advantages. The feeding combine harvester adopts the mode of reel and cutter to realize the cutting of stalk plants. Due to the difference in the structure of the header, it is directly related to the operation effect ratio. For example, the cleanliness of threshing, the impact on the quality of rice, and the utilization of straw and other issues. The traditional full-feed combine harvester has difficult problems in rice lodging and straw utilization. For example, it has just rained locally, not only the working environment in the field is bad, but also when the rice lodging is serious. Type combine harvesters cannot solve the harvesting...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01D41/06A01D41/14A01F12/22A01F12/44

Inventor 黄春林黄伟群陈晓谭廙陈家坤

Owner GUANGXI GUIGANG COMBINE HARVESTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com