Dynamic control system and method for batching accuracy of concrete mixing plant

A technology of dynamic control and mixing station, which is applied in the direction of mixing operation control, mixing operation control device, batching and batching instrument, etc., can solve the problems of frequent metering out of tolerance and insufficient precision of raw material batching, achieve high batching accuracy, reduce personnel configuration and Resource allocation, the effect of ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

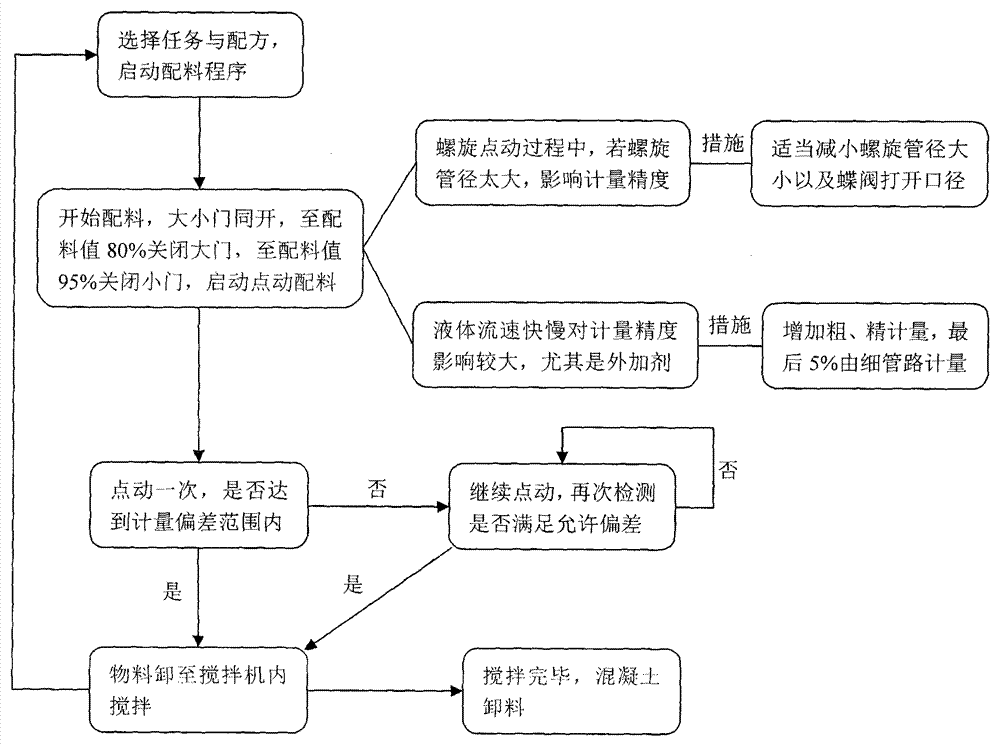

[0020] Embodiment 1, in conjunction with attached figure 1 And attached figure 2 The present invention is described further:

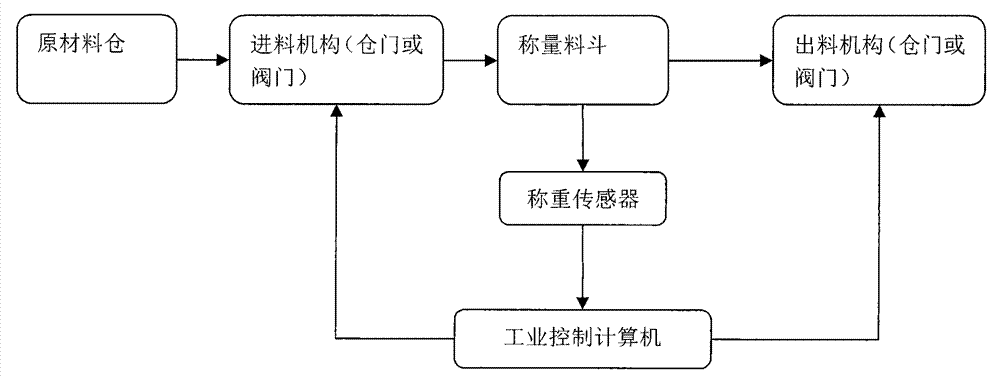

[0021] The system of the present invention includes several parts such as a batching device, a weighing sensor, a batching instrument (PLC) and an industrial control computer. In particular, the couplings and soft connections between each part are organically unified to ensure that the connection is moderately tight.

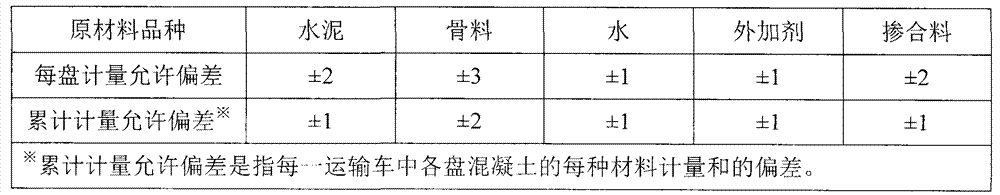

[0022] The batching device of the above system adopts the "double-door method" and "double-pipe method" according to the type of material to achieve rough weighing and fine weighing, that is, two discharge doors, one large and one small, and two pipelines, one thick and one thin, are designed, respectively responsible for Transportation of powder and liquid materials.

[0023] The load cell of the above system is a high-precision pull-type load cell, which has the characteristics of high sensitivity, good linearity, small zero drift a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com