Analog simulation experiment system and method based on 3D printing rapid prototyping technology

A technology similar to simulation experiments and 3D printing, applied in ceramic molding machines, auxiliary molding equipment, chemical instruments and methods, etc., can solve the problems of high labor intensity, long laying time, low degree of simulation similarity, etc. The high degree of automation, the effect of reducing the difficulty of laying and labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

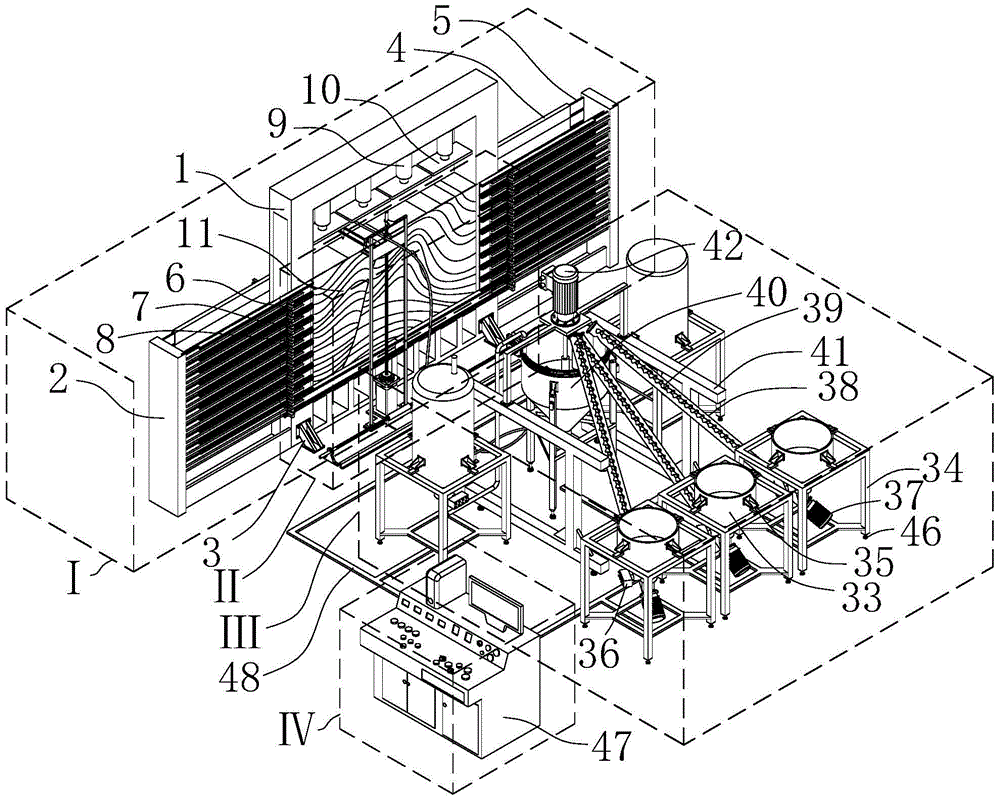

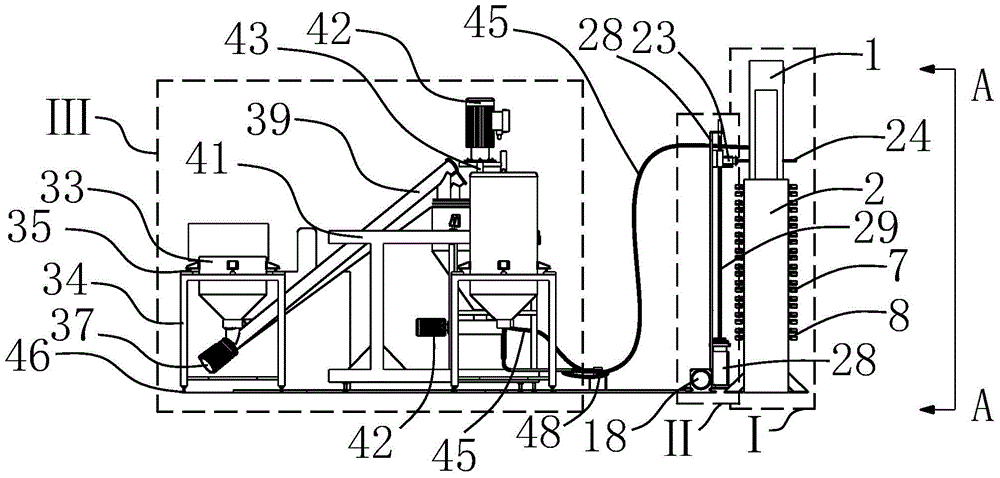

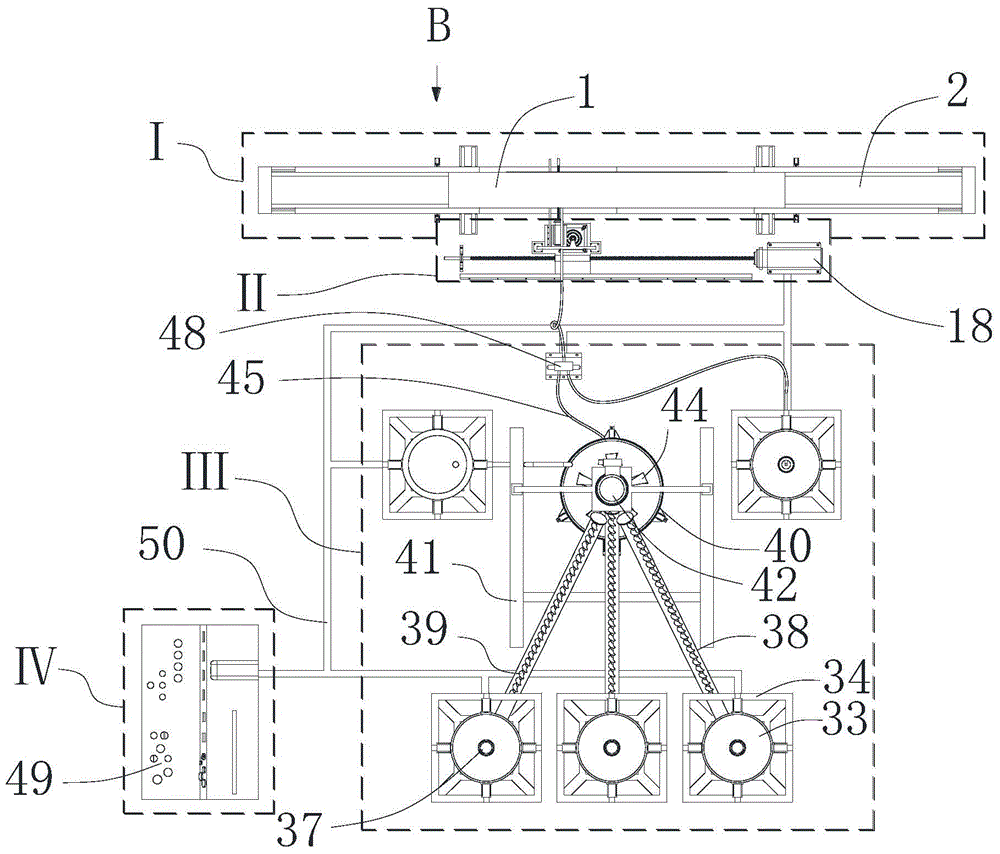

[0053] combined with Figures 1 to 7 The specific embodiment of the present invention is described further:

[0054] A similar simulation experiment system based on 3D printing rapid prototyping technology, including batching module III, printing and laying module II, experiment module I, and control module IV. The batching module is connected to the experimental module through the printing and laying module, and the control module is connected to and controls the batching module. , Print paving module and experiment module.

[0055] The control module forms a 3D digital model similar to the simulation experiment. The control module controls the experimental module to adjust to a state suitable for printing the 3D digital model, and controls the batching ratio of the batching module through the solenoid valve, and controls the printing material distribution module through the direction control mechanism and the reversing valve. Three-dimensional paving is carried out in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com