Concrete crack detection system and method based on 3D printing and wireless sensing

A 3D printing and wireless sensing technology, applied in the direction of measuring devices, electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve the problems of manpower, material resources and inaccurate measurement data, and achieve control of concrete damage and monitoring results Accurate, highly sensitive results

Inactive Publication Date: 2019-01-11

DONGHUA UNIV

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, there are mainly the following methods for monitoring concrete cracks: Patent CN105403161A provides a method for detecting the width of cracks in concrete structures using an optical fiber sensor, including a method for calculating the width of concrete cracks. Changes in the relationship between the strain of concrete and a calculation method for concrete cracks are proposed. This method has high calculation accuracy, but it requires a certain amount of manpower and material resources to lay out optical fiber sensors in concrete structures, and it is relatively complicated; patent CN106839958A provides a simple concrete crack The monitoring and measuring device and method, arrange a number of pure fine copper wires in the crack development area of the concrete structure, and arrange an alloy wire next to each pure fine copper wire, and form a loop through the wire and the data acquisition instrument, when the concrete When cracks occur, the strain changes and can be monitored. This invention has a simple structure and is easy to manufacture, but the measurement data is not accurate enough.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0037] step one:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

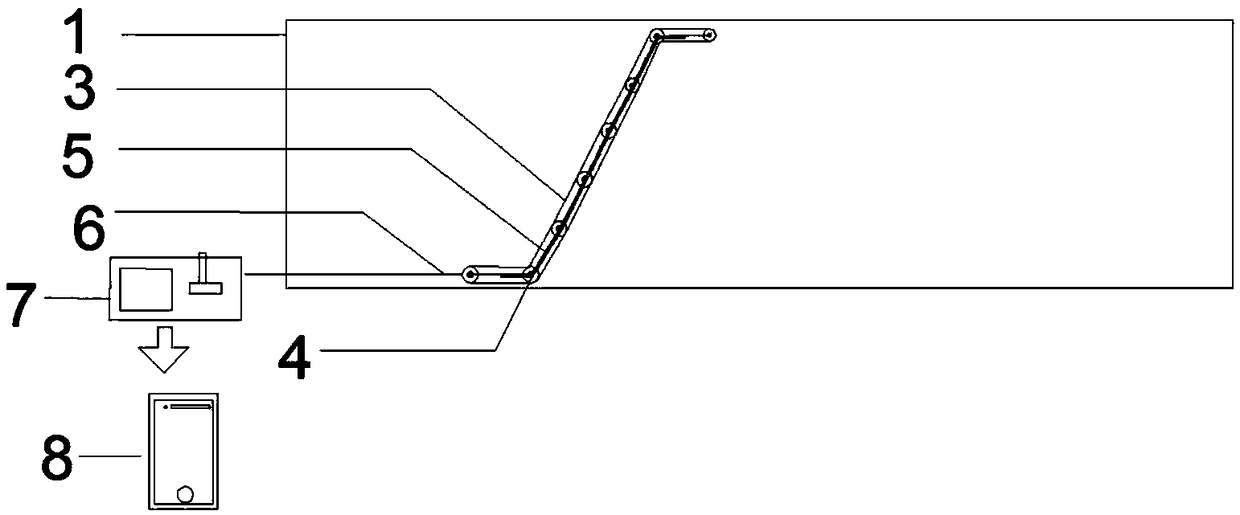

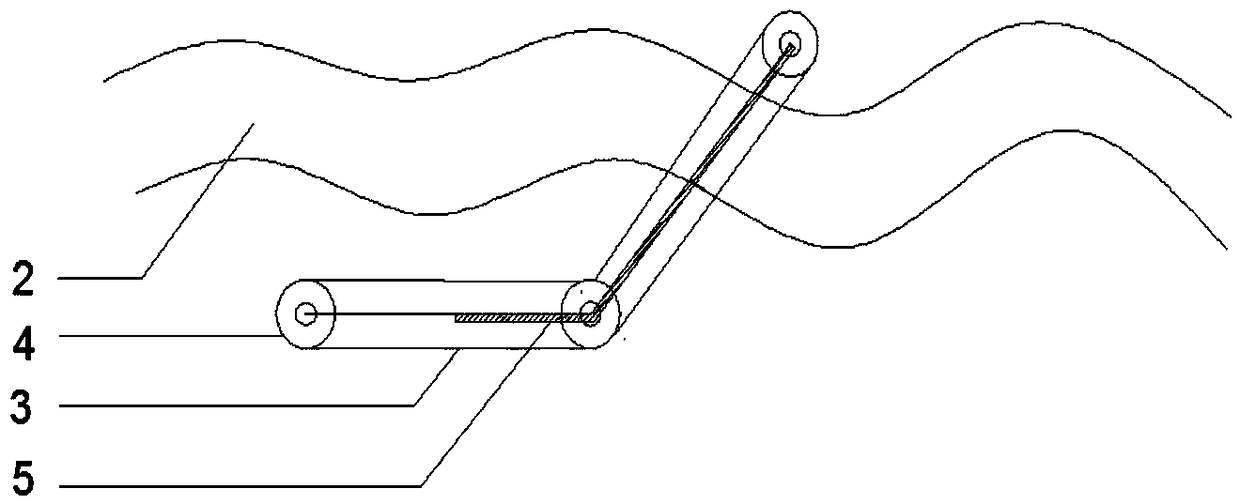

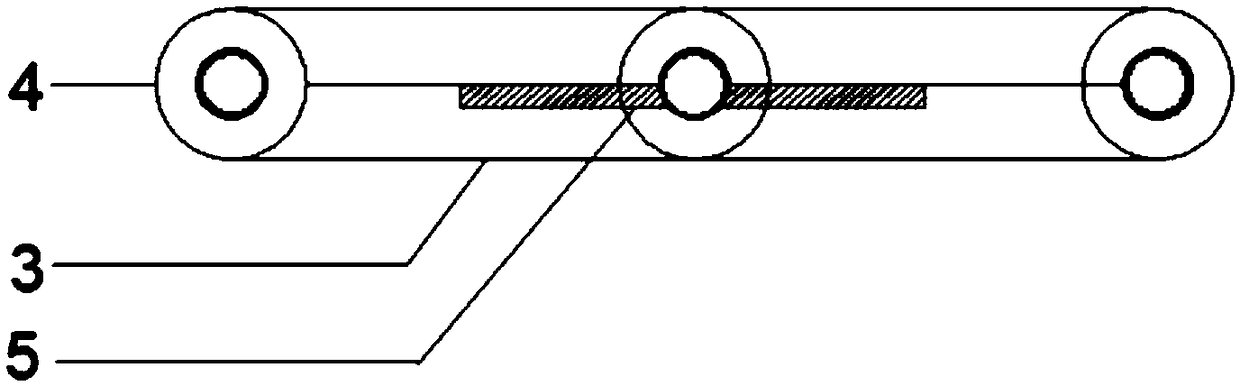

The invention provides a concrete crack detection system based on 3D printing and wireless sensing. The system comprises a plurality of 3D printed protective shells which are rotatably connected through steel hinges; the two half sections of each Flex bending sensor are arranged in the two adjacent protective shells respectively; the two protective shells at the two ends of the outermost side arehorizontally arranged on concrete; the protective shells in the middle are obliquely arranged on the concrete in a straight line shape; each Flex bending sensor is connected with a GPRS acquisition system through a connecting cable; and the GPRS acquisition system is wirelessly connected with a wireless signal collection terminal. The invention further provides a concrete crack detection method based on 3D printing and wireless sensing. The concrete cracks and the cracking degree can be detected accurately and conveniently in real time; the long-distance monitoring of the concrete cracks is achieved; the system and the method have the advantages of accurate monitoring result, long monitoring time and convenient implementation; and the concrete damage can be effectively controlled.

Description

technical field [0001] The invention relates to a concrete crack detection system and method based on 3D printing and wireless Flex sensing technology, which is mainly used in the measurement of cracks in concrete or other components in civil engineering, and belongs to the application of bending sensing technology in the field of structural health monitoring. Background technique [0002] Concrete cracks are a noteworthy problem in engineering. Once microscopic concrete cracks develop, they may cause cracking, deformation or even destruction of structures. Therefore, the monitoring of concrete cracks is particularly important. [0003] At present, there are mainly the following methods for monitoring concrete cracks: Patent CN105403161A provides a method for detecting the width of cracks in concrete structures using an optical fiber sensor, including a method for calculating the width of concrete cracks. Changes in the relationship between the strain of concrete and a calcu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01B7/16G01B7/30

CPCG01B7/18G01B7/30

Inventor 张一帆杨语尧洪成雨

Owner DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com