A mud-resistant polycarboxylate water reducer, its preparation method and use method

A technology of polycarboxylate and water reducer, which is applied in the field of mud-resistant polycarboxylate water reducer, which can solve the problems of high sensitivity to aggregate mud content, reduced strength of hardened concrete, and reduced water-reducing and dispersing ability. , to achieve the effects of avoiding adverse effects, convenient operation, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

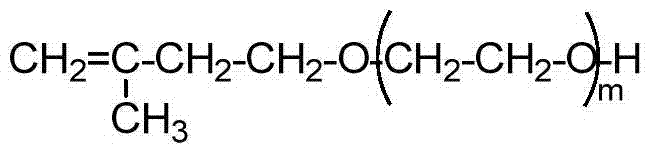

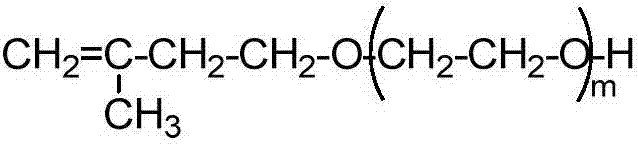

Image

Examples

Embodiment 1

[0029] Accurately weigh 155 parts by weight of water for use in the following steps;

[0030] a: Preparation of Solution A

[0031] Accurately weigh 9 parts by weight of acrylic acid, 6 parts by weight of hydroxypropyl acrylate, 2 parts by weight of methyl acrylate, 2 parts by weight of aminotrimethylene phosphonic acid, 2 parts by weight of maleic anhydride, 1.25 parts by weight of sodium methacrylate and 44 parts by weight of water, stirred and mixed evenly, pumped into the high-level tank A, ready to add dropwise;

[0032] b: Preparation of Solution B

[0033] Accurately weigh 0.6 parts by weight of mercaptoacetic acid, 0.4 parts by weight of mercaptopropionic acid and 56 parts by weight of water, stir and mix evenly, pump into the high level tank B, and prepare dropwise;

[0034] c: Preparation of Solution C

[0035] Accurately weigh 100 parts by weight of isopentenol polyoxyethylene ether (DD-524) with a number average molecular weight of 1200, 1.5 parts by weight of a...

Embodiment 2~ Embodiment 5

[0039] According to the method and steps of Example 1, the anti-mud type polycarboxylate superplasticizer of the present invention was prepared according to the formula in Table 1. According to the addition amount shown in Table 1, the anti-mud type polycarboxylate water-reducer obtained in Examples 1-5 (abbreviated as S1-S5) of the present invention was added to cement slurry and concrete with different mud contents, and the obtained cement The performance data of paste and concrete are also shown in Table 1.

[0040] Among them, the commercially available mud-resistant polycarboxylate superplasticizer was purchased from Wuhan Jincarbox Technology Co., Ltd., the model is JS-900, referred to as D1.

[0041] Among them, the type of cement used in cement slurry and concrete in Table 1 is P.O.42.5, and the manufacturer is Shanghai Jinshan Cement Factory.

[0042] Among them, the slurry test is carried out according to the standard of GB / T 8077-2000 "Concrete Admixture Homogeneit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com