Compound mineral admixture

A technology for compound minerals and raw materials, applied in the field of highly active compound mineral admixtures, can solve the problems of high energy consumption and poor technical economy, and achieve the effects of increasing the heat of hydration, reducing energy consumption, and reducing consumption of natural resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Steel slag fine powder 30wt%,

[0020] S95 grade slag fine powder 66wt%,

[0021] Sintered desulfurization ash 2wt%,

[0022] Desulfurization gypsum powder 2wt%.

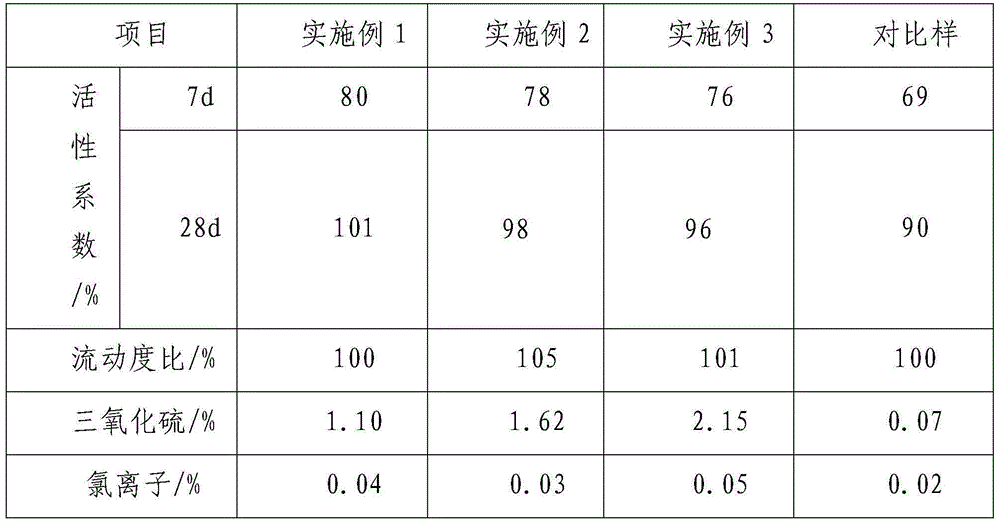

[0023] The above components are mechanically stirred and mixed uniformly to make samples, and the performance of the composite admixture samples is tested with reference to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete". The benchmark cement is Conch brand 42.5 Portland cement, and the test results are shown in Table 1.

Embodiment 2

[0025] Steel slag fine powder 35wt%,

[0026] S95 grade slag fine powder 61wt%,

[0027] Sintered desulfurization ash 1wt%,

[0028] Desulfurization gypsum powder 3wt%.

[0029] The above components are mechanically stirred and mixed uniformly to make samples, and the performance of the composite admixture samples is tested with reference to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete". The benchmark cement is Conch brand 42.5 Portland cement, and the test results are shown in Table 1.

Embodiment 3

[0031] Steel slag fine powder 40wt%,

[0032] S95 grade slag fine powder 54wt%,

[0033] Sintered desulfurization ash 2wt%,

[0034] Desulfurization gypsum powder 4wt%.

[0035] The above components are mechanically stirred and mixed uniformly to make samples, and the performance of the composite admixture samples is tested with reference to GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete". The benchmark cement is Conch brand 42.5 Portland cement, and the test results are shown in Table 1.

[0036] Note: The comparison sample composition is:

[0037] Steel slag fine powder 30wt%, S95 grade slag fine powder 70wt%.

[0038] Table 1 Composite mineral admixture performance test results

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com