Fully-enclosed automatic ready-mixed concrete feeding system and operation method

A technology for ready-mixed concrete and automatic feeding, which is used in mixing operation control, chemical instruments and methods, mixing plants, etc. The effect of fast speed and high delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

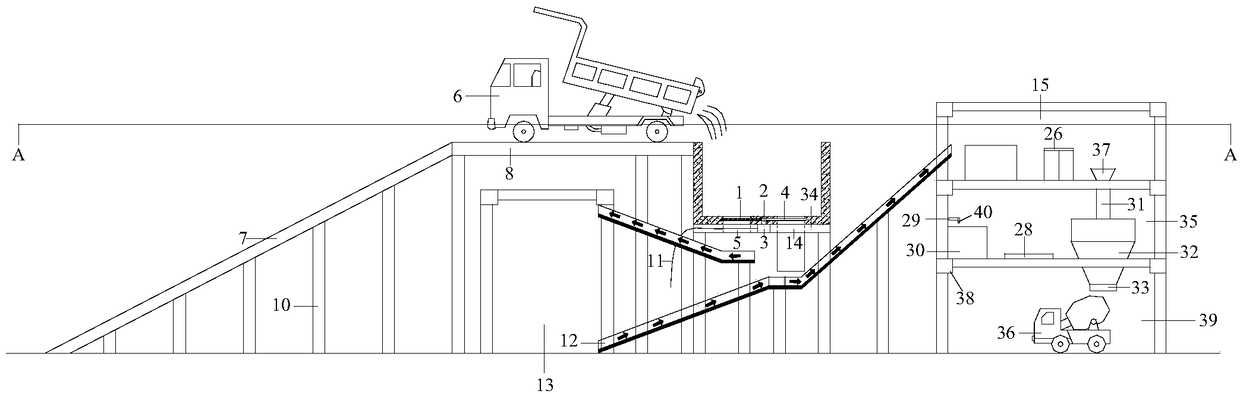

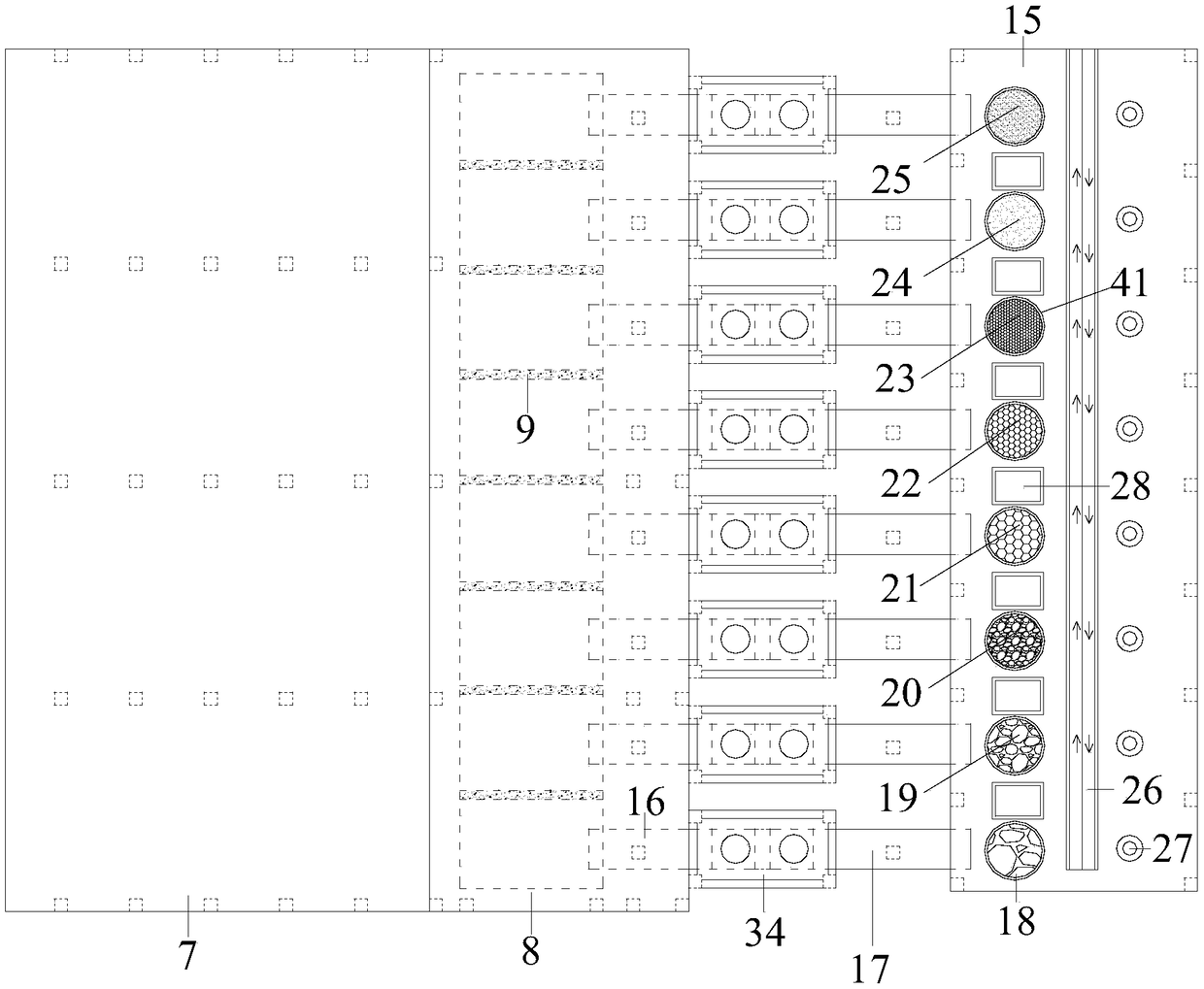

[0032] The fully enclosed automatic feeding system for ready-mixed concrete includes a concrete unloading system and a concrete feeding system;

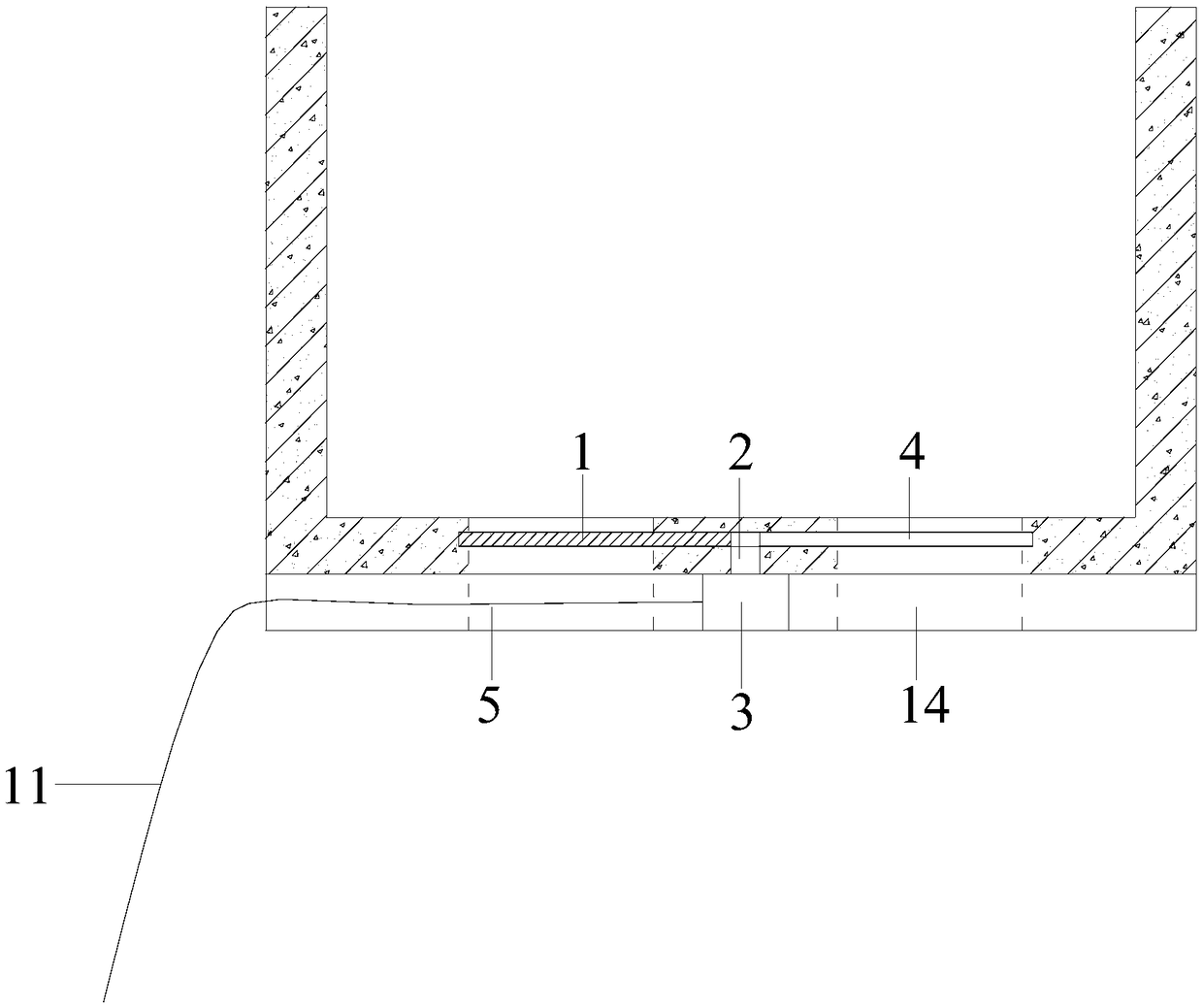

[0033] The concrete unloading system includes a gentle slope 7, a discharge transition chute 34, a dumping platform 8, a storage yard 13, a first conveyor belt 16, a second conveyor belt 17, a third conveyor belt 12 and a high-level batching bin 15; the upper end of the gentle slope 7 is connected to the dumping Platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com