Composite clay substituting natural sand and premixed concrete adopting composite clay as raw material

A technology of ready-mixed concrete and natural sand, applied in the field of ready-mixed concrete, which can solve problems such as lowering the use value and air quality pollution, and achieve high strength, improved corrosion resistance and durability, great market promotion value and application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The rice husk was washed and dried with water and reacted with hydrochloric acid with pH=1, then dried, calcined and ground to obtain rice husk ash, wherein the calcining temperature was 500°C.

[0034] The shell powder is recovered and cleaned from discarded shells, washed with 10% by mass NaOH alkali for 0.5-24 hours, dried and ground to obtain the shell powder.

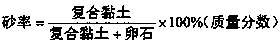

[0035] Mix clay, shell powder, fly ash, slag, rice husk ash, quicklime, and sodium carbonate with water in proportion. After ball milling, use a roller compactor to compact the mixed powder. Drying, granulation, sieving and grading to obtain composite clay, the specific formulation is shown in Table 1.

[0036]

Embodiment 2

[0038] Samples of the composite clay prepared in Example 1 were prepared respectively, and the standards of "Sand for Construction" (GB / T14684-2011) and "Quality and Inspection Standards for Sand and Stone for Ordinary Concrete" (JGJ 52) were used to compare the samples. The indicators were tested and the results are shown in Table 2.

[0039]

[0040] As can be seen from the test results in Table 2, the composite clay sand grains of the present invention meet the requirements of the standards of "Sand for Construction" (GB / T14684-2011) and "Sand and Stone Quality and Inspection Standards for Ordinary Concrete" (JGJ 52); The unique microstructure of rice husk ash and shell powder makes the bulk density and apparent density relatively high.

Embodiment 3

[0042] In order to verify the performance of ready-mixed concrete using composite clay, shell powder, and rice husk ash as raw materials, we conducted a component substitution verification test with the same ratio and tested related indicators.

[0043] According to the components and proportions in Table 3, the ready-mixed concrete is mixed at room temperature, and its slump and compressive strength are tested in accordance with "Concrete Admixtures" (GB8076-2006) and "Experimental Methods for Mechanical Properties of Ordinary Concrete". "Standard" (GB / T50081-2002) requires testing, and the specific test results are shown in Table 3.

[0044] The fine aggregate in the blank example in table 3 is natural medium sand, and the mineral powder is the fly ash of class F of class II; the fine aggregate in the test example is numbered 1, 3, 5, The composite clay of 7, the mineral powder is the mineral powder in the present invention, and the mass percentage of the mineral powder of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com