High fly ash commercial concrete or ready-mixed concrete

A technology for commercial concrete and ready-mixed concrete, applied in the field of commercial concrete or pre-mixed concrete, can solve the problems affecting the durability of concrete structures, large fluctuations in concrete quality, cracking of concrete structures, etc. Satisfaction, low hydration temperature rise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

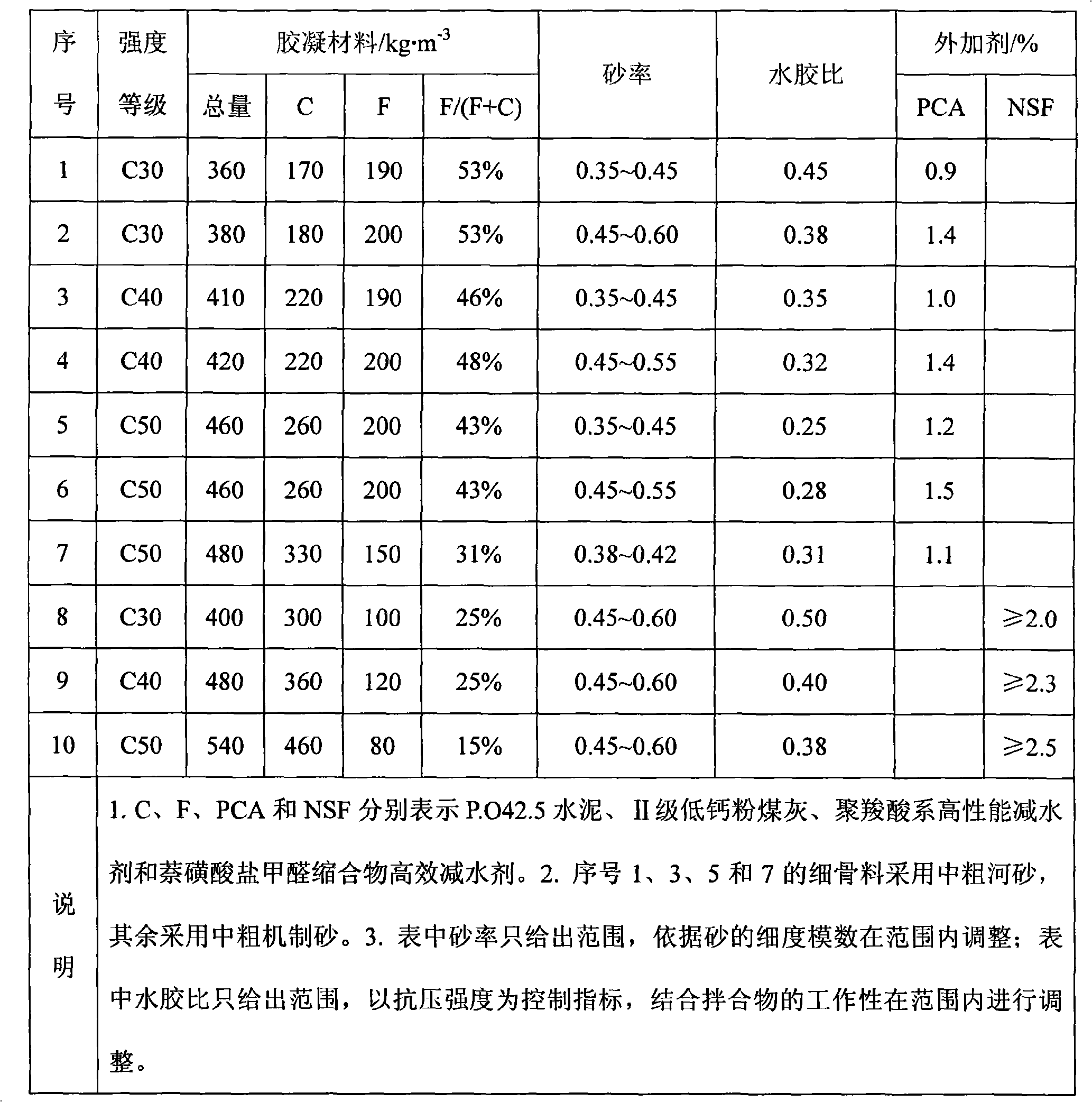

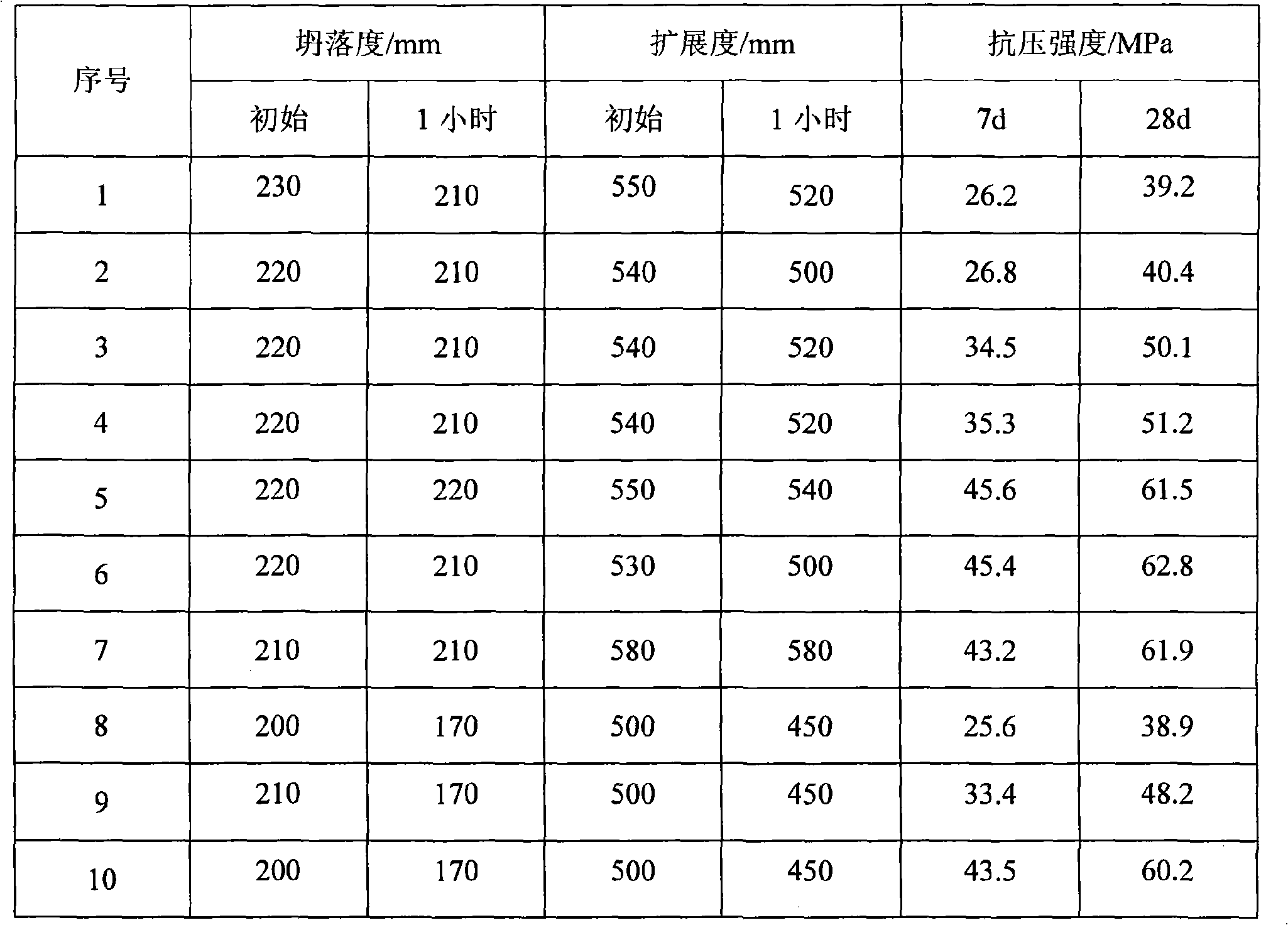

[0014] Preferred embodiment of the present invention (compared with ordinary concrete mixed with naphthalene-based high-efficiency water reducer):

[0015] Raw materials: Portland cement or ordinary Portland cement with a strength of not less than 42.5MPa, national standard I or II fly ash, fine sand with a fineness of 1.7-2.2 or intermediate sand with a fineness of 2.3-3.0 (natural sand or artificial sand), gravel with a particle size within the range of 5-31.5mm, polycarboxylate-based high-performance water-reducer and naphthalene-based high-efficiency water-reducer for comparison, and water, according to the mixing ratio listed in Table 1, Measured separately.

[0016] Preparation method: It is required that the metering system of the mixing system, especially the metering system of mixing water and the metering system of chemical admixtures, should have high precision, and the error should be less than 0.03%. Adjust the amount of mixing water; the measurement error of fly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com