A kind of anti-cracking and anti-seepage ready-mixed concrete and preparation process thereof

A technology of ready-mixed concrete and aminoethanesulfonic acid, applied in the field of building materials, can solve the problems of high cost, crack resistance and anti-seepage performance need to be further improved, insufficient crack resistance performance of concrete, etc., achieving long service life, improved crack resistance and anti-seepage. Penetration performance, the effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

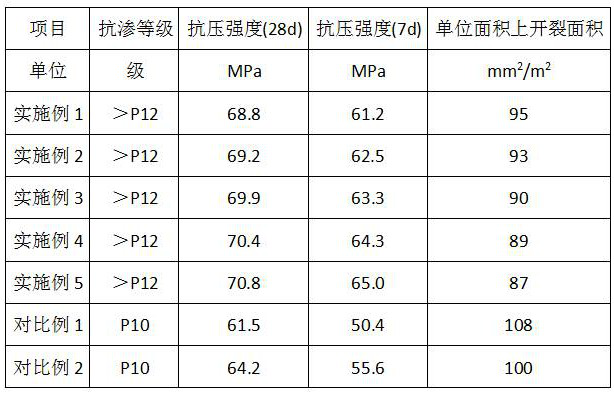

Examples

Embodiment 1

[0033] An anti-cracking and anti-seepage ready-mixed concrete, comprising the following components in parts by weight: 100 parts of cement, 1,000 parts of crushed stone, 650 parts of sand, 50 parts of slag powder, 3 parts of corn slag powder, 7-fluorine -5-oxo-8-(4-(2-propenyl)-1-piperazinyl)-5H-thiazolo[3,2-a]quinoline-4-carboxylic acid / methacrylate group modified 5 parts of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid copolymer, 8 parts of waste Kevlar fiber, 8 parts of UEA expansion agent, 10 parts of wollastonite fiber, water-soluble hyperbranched 3 parts of polyamide, 1 part of hyperbranched polysulfide polyamine, 2 parts of nano borosilicate, and 60 parts of water.

[0034] The 7-fluoro-5-oxo-8-(4-(2-propenyl)-1-piperazinyl)-5H-thiazolo[3,2-a]quinoline-4-carboxylic acid / methyl The preparation method of base acrylate group modified N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid copolymer, comprising the following steps:

[0035] Step D1, adding N,N-bis(2-hydro...

Embodiment 2

[0042] An anti-cracking and anti-seepage ready-mixed concrete, comprising the following components in parts by weight: 115 parts of cement, 1020 parts of crushed stone, 670 parts of sand, 53 parts of slag powder, 3.5 parts of corn slag powder, 7-fluorine -5-oxo-8-(4-(2-propenyl)-1-piperazinyl)-5H-thiazolo[3,2-a]quinoline-4-carboxylic acid / methacrylate group modified 6 parts of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid copolymer, 9 parts of waste Kevlar fiber, 10 parts of UEA expansion agent, 12 parts of wollastonite fiber, water-soluble hyperbranched 3.5 parts of polyamide, 1.2 parts of hyperbranched polysulfide polyamine, 2.5 parts of nano borosilicate, and 70 parts of water.

[0043] The 7-fluoro-5-oxo-8-(4-(2-propenyl)-1-piperazinyl)-5H-thiazolo[3,2-a]quinoline-4-carboxylic acid / methyl The preparation method of base acrylate group modified N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid copolymer, comprising the following steps:

[0044] Step D1, adding N,N-bi...

Embodiment 3

[0051] An anti-cracking and anti-seepage ready-mixed concrete, comprising the following components in parts by weight: 130 parts of cement, 1050 parts of crushed stone, 700 parts of sand, 55 parts of slag powder, 4 parts of corn slag powder, 7-fluorine -5-oxo-8-(4-(2-propenyl)-1-piperazinyl)-5H-thiazolo[3,2-a]quinoline-4-carboxylic acid / methacrylate group modified 6.5 parts of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid copolymer, 11 parts of waste Kevlar fiber, 12 parts of UEA expansion agent, 13 parts of wollastonite fiber, water-soluble hyperbranched 4 parts of polyamide, 1.5 parts of hyperbranched polysulfide polyamine, 3 parts of nano borosilicate, and 80 parts of water.

[0052] The 7-fluoro-5-oxo-8-(4-(2-propenyl)-1-piperazinyl)-5H-thiazolo[3,2-a]quinoline-4-carboxylic acid / methyl The preparation method of base acrylate group modified N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid copolymer, comprising the following steps:

[0053] Step D1, adding N,N-bis(2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com