Construction method of rain and sewage purification treatment system in ready-mixed concrete production plant area

A technology for ready-mixed concrete and purification treatment, which is applied in the fields of construction and civil engineering, can solve the problems of high energy consumption for mixing, low sewage treatment efficiency, and pollution reduction, and achieves the effects of good effect, high construction efficiency, and improved seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

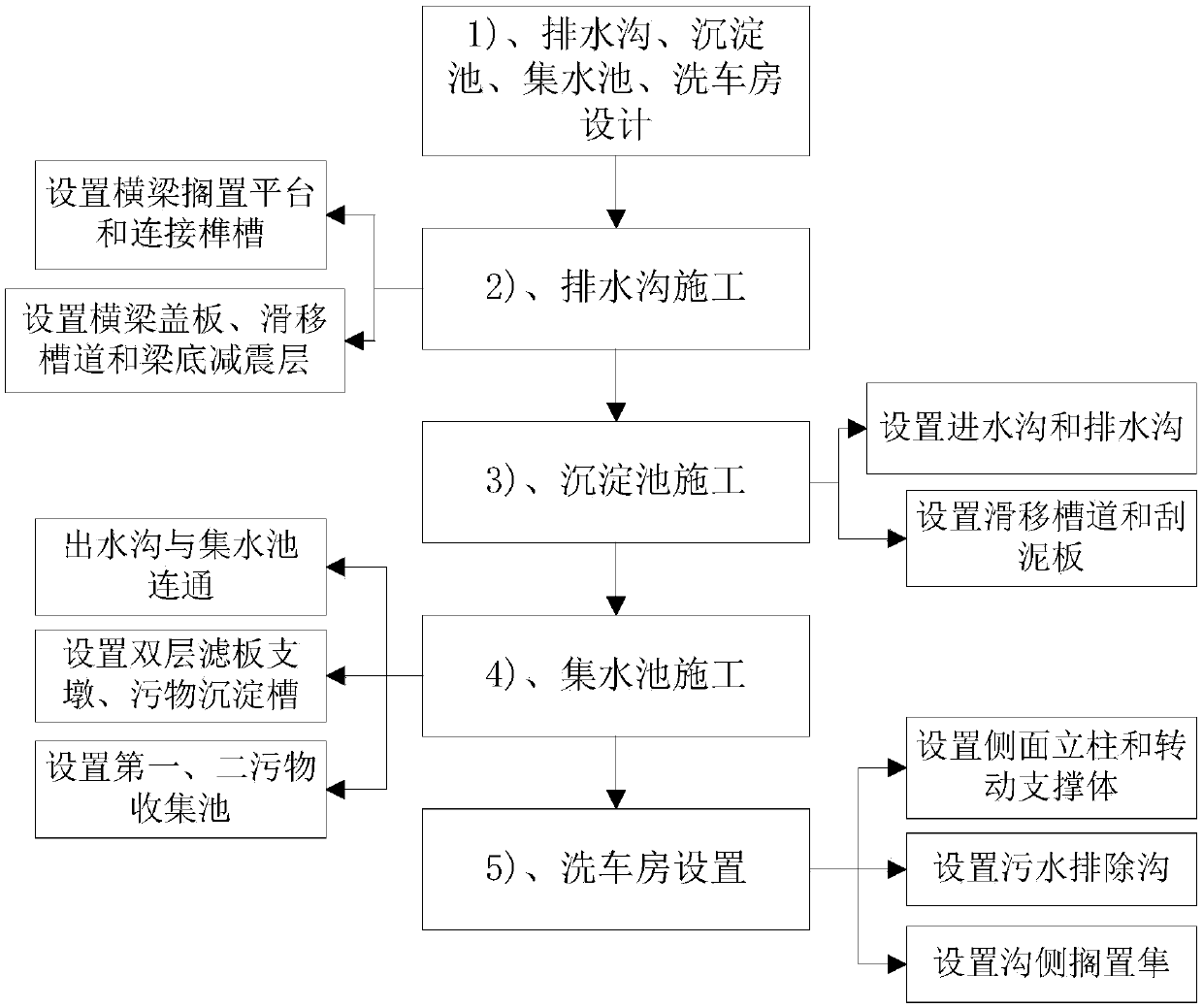

[0031] refer to figure 1 As shown, the construction method of the rainwater purification treatment system in the ready-mixed concrete production plant includes the following construction steps:

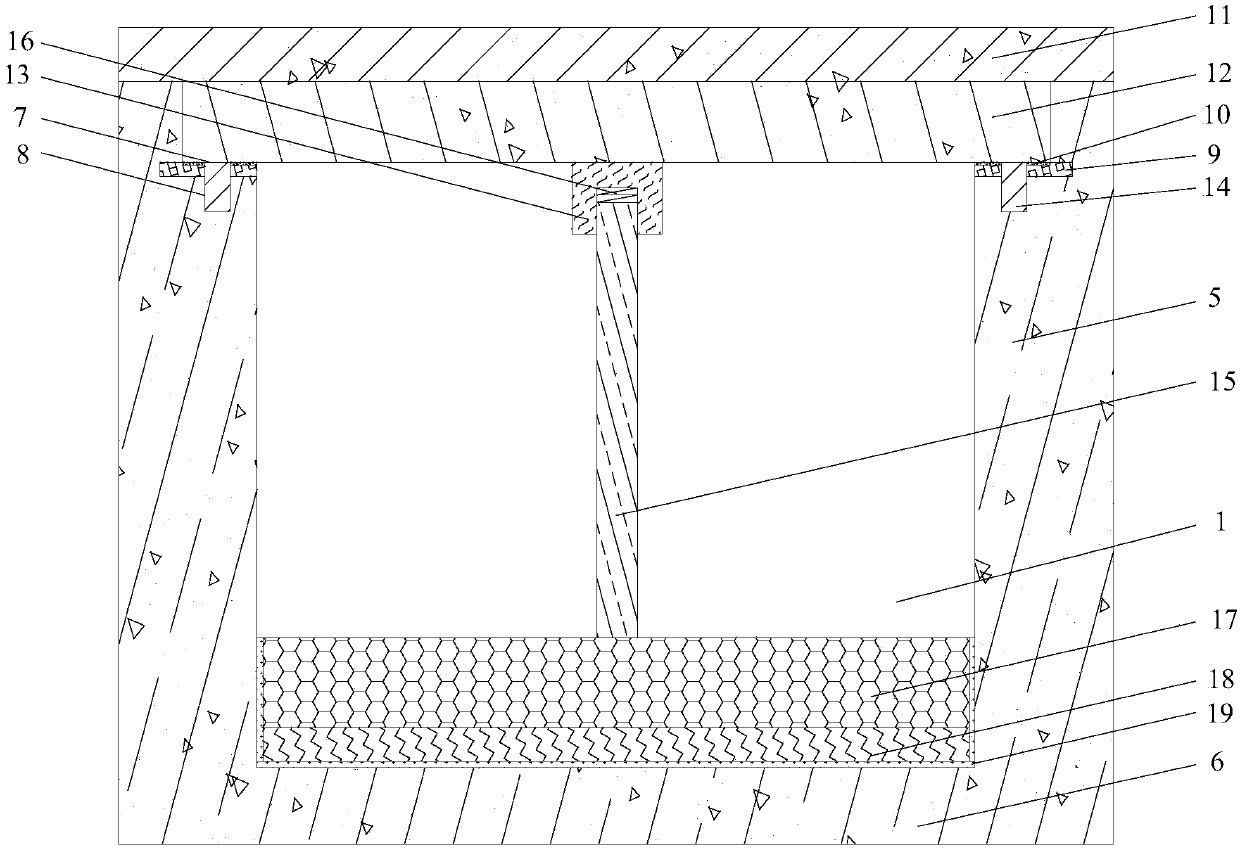

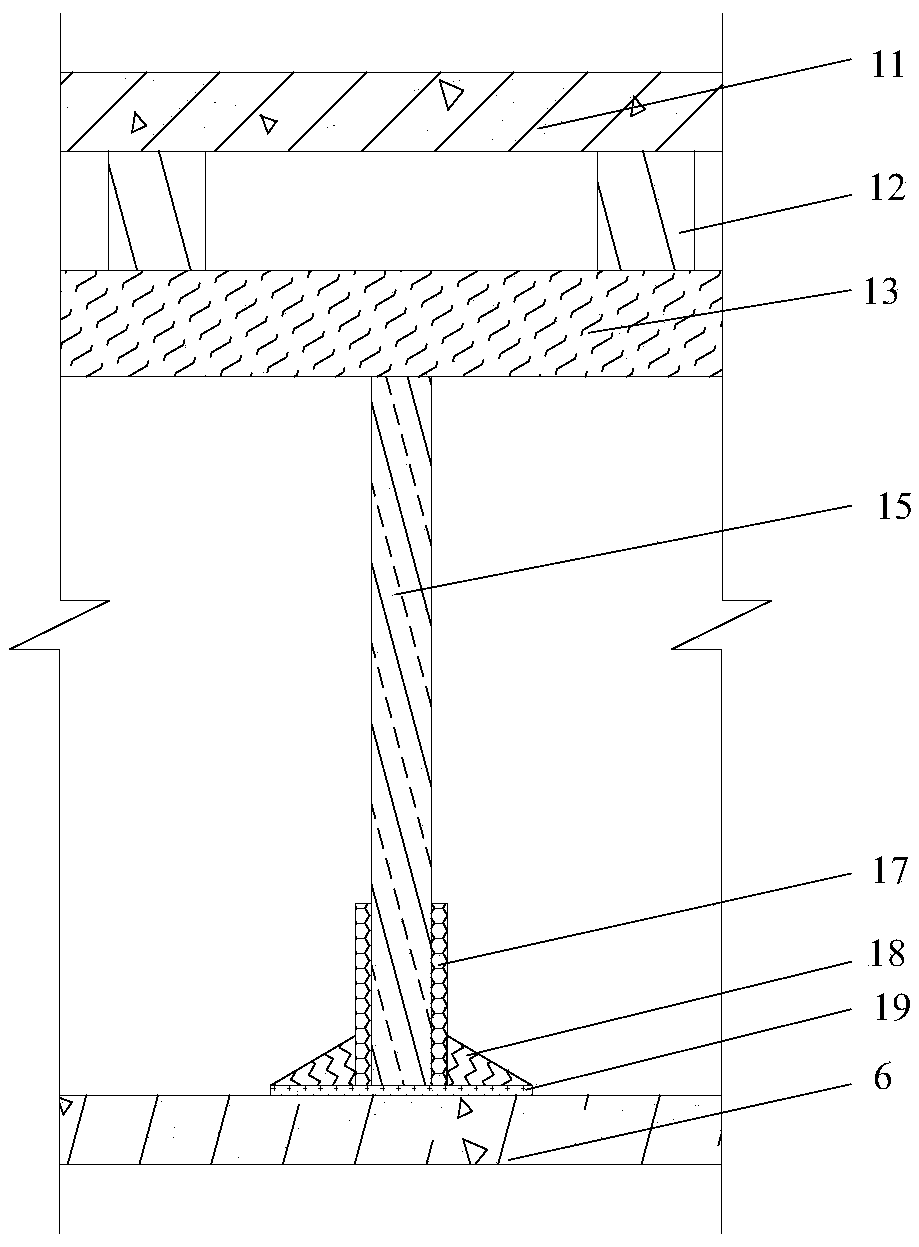

[0032]1) Design of drainage ditch 1, sedimentation tank 2, sump 3, and car wash room 4: according to the layout of the ready-mixed concrete production plant, determine the cross-sectional dimensions of drainage ditch 1, sedimentation tank 2, sump 3, and car wash room 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com