A kind of ready-mixed recycled concrete and preparation method thereof

A technology of recycled concrete and ready-mixed concrete, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., and can solve the problem of low addition of recycled coarse aggregate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

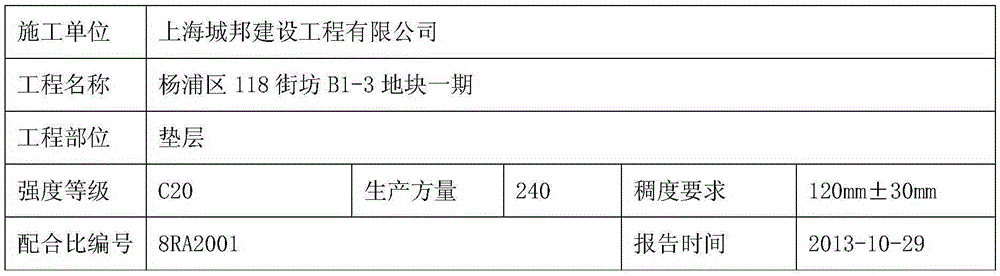

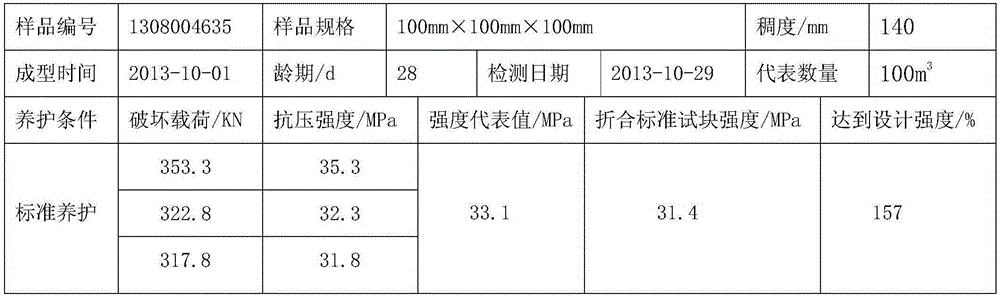

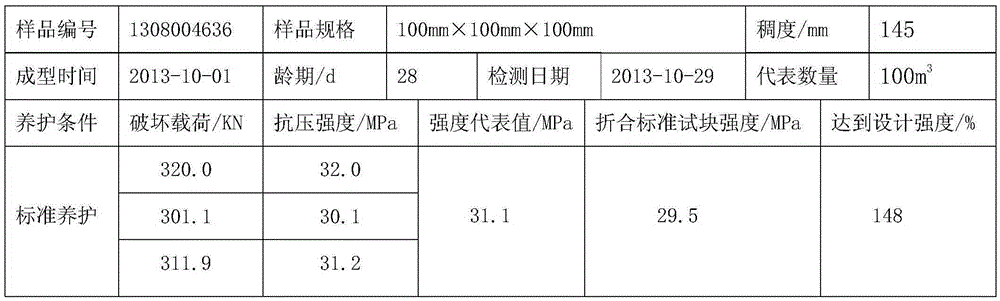

[0027] Ready-mixed recycled concrete is composed of the following weights per cubic meter of ready-mixed concrete: 133kg of 42.5 grade cement, 327kg of the first yellow sand, 608kg of the second yellow sand, 387kg of natural stones, 527kg of recycled coarse aggregate, 71kg of fly ash, and additives 2.66kg, mineral powder 129kg, water 122kg, the slump of the ready-mixed recycled concrete is 120±30mm.

[0028] The preparation method of the ready-mixed recycled concrete is to first add the first yellow sand, the second yellow sand, mineral powder, 42.5 grade cement and fly ash according to the order of feeding, after stirring for 20 seconds, then add natural stones and recycled coarse aggregate, and stir 20 seconds, finally add the water and admixtures, and blend for 60 seconds out of the blender.

[0029] The strength grade of the ready-mixed recycled concrete in this embodiment is C20.

[0030] The detection method of ready-mixed recycled concrete in this embodiment is carried...

Embodiment 2

[0040] Ready-mixed recycled concrete is composed of the following weights per cubic meter of ready-mixed concrete: 152kg of 42.5 grade cement, 307kg of the first yellow sand, 571kg of the second yellow sand, 404kg of natural stones, 547kg of recycled coarse aggregate, 80kg of fly ash, and additives 3.04kg, mineral powder 148kg, water 123kg, the slump of the ready-mixed recycled concrete is 120±30mm.

[0041] The preparation method of the ready-mixed recycled concrete is to first add the first yellow sand, the second yellow sand, mineral powder, 42.5 grade cement and fly ash according to the order of feeding, after stirring for 20 seconds, then add natural stones and recycled coarse aggregate, and stir 20 seconds, finally add the water and admixtures, and blend for 60 seconds out of the blender.

[0042]The strength grade of ready-mixed recycled concrete in this embodiment is C25.

[0043] The detection method of ready-mixed recycled concrete in this embodiment is implemented ...

Embodiment 3

[0049] Ready-mixed recycled concrete is composed of the following weights per cubic meter of ready-mixed concrete: 164kg of 42.5-grade cement, 300kg of the first yellow sand, 559kg of the second yellow sand, 402kg of natural stones, 547kg of recycled coarse aggregate, 76kg of fly ash, and additives 3.20kg, mineral powder 160kg, water 126kg, the slump of the ready-mixed recycled concrete is 120±30mm.

[0050] The preparation method of the ready-mixed recycled concrete is to first add the first yellow sand, the second yellow sand, mineral powder, 42.5 grade cement and fly ash according to the order of feeding, after stirring for 20 seconds, then add natural stones and recycled coarse aggregate, and stir 20 seconds, finally add the water and admixtures, and blend for 60 seconds out of the blender.

[0051] The strength grade of the ready-mixed recycled concrete in this embodiment is C30.

[0052] The detection method of ready-mixed recycled concrete in this embodiment is carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com