Carbon fiber composite arm rest, method for manufacturing same and concrete pump truck including same

A composite material and production method technology, which is applied in the field of concrete pump trucks and carbon fiber composite booms, can solve the problems of fatigue fracture of high-strength steel booms, poor weldability of high-strength steel plates, and low fatigue resistance, so as to reduce production costs. Reduced equipment cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Carbon fiber prepreg: The weight raw material is 70% of the fiber material T300 carbon fiber produced by Japan Toray Company and the resin matrix based on AG-80 epoxy resin produced by Shanghai Synthetic Resin Research Institute is 30% by weight.

[0052] production method:

[0053] First inflate the stretchable airbag 1 once through the inflation and deflation port 11 of the stretchable airbag 1 to form an airbag with a first state with an internal pressure of 0.3 MPa, and form an airbag with a first state. The carbon fiber prepreg 2 is laid on the outer surface to form the first transition component. Put the first transition assembly into the vacuum bag 3 and seal it, and evacuate the vacuum bag 3 to an internal pressure of -0.1MPa. Under the interaction between the vacuum bag 3 and the air bag in the first state, the The carbon fiber prepreg is fixed in the first compression to obtain the intermediate transition components. Put the intermediate transition assembly ...

Embodiment 2

[0055] Carbon fiber prepreg: the fiber material T700 fiber produced by Toray Corporation of Japan with a weight content of 50% and the resin matrix based on E-51 epoxy resin produced by the Bluestar Group Wuxi Resin Factory with a weight content of 50%.

[0056] production method:

[0057] First inflate the stretchable airbag 1 once through the inflation and deflation port 11 of the stretchable airbag 1 to form an airbag with a first state with an internal pressure of 0.2 MPa, and form an airbag with a first state. Spray the WB-411 release agent of AXEL company on the outer surface, lay the carbon fiber prepreg 2 on the outer surface of the airbag with the first state sprayed with the release agent, and put the first transition assembly into the vacuum bag 3 Seal in the center, and vacuumize the vacuum bag 3 to an internal pressure of -0.07MPa, and carry out the first compression and fixation of the carbon fiber prepreg under the interaction between the vacuum bag 3 after vacu...

Embodiment 3

[0059]Carbon fiber prepreg: 60% by weight of the fiber material T700 fiber produced by Toray Corporation of Japan and 40% by weight of the matrix resin produced by ACG Company based on MTM82 phenolic resin.

[0060] production method:

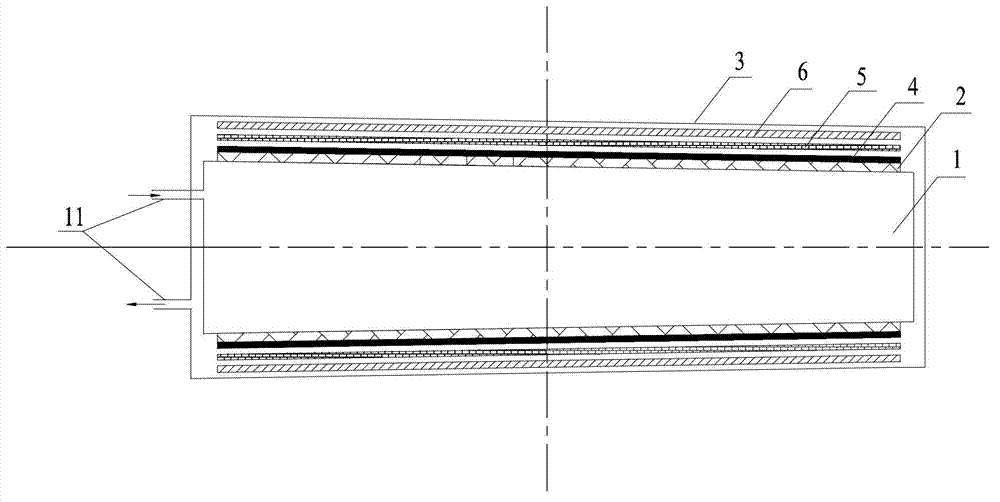

[0061] First inflate the stretchable airbag 1 once through the inflation and deflation port 11 of the stretchable airbag 1 to form an airbag with a first state with an internal pressure of 0.4 MPa, and form an airbag with a first state. The release agent is sprayed on the outer surface, and the prepreg 2 is laid on the outer surface of the airbag in the first state sprayed with the release agent. On the outer surface of the prepreg 2, the release cloth 4, the perforated isolation film 5, and the air felt 6 are sequentially laid to form a first transition component. Put the first transition assembly into the vacuum bag 3 and seal it, and evacuate the vacuum bag 3 to an internal pressure of -0.085MPa. Under the interaction between the vacuum bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com