Asphalt concrete regenerative heating and heat-preservation mixing carrier vehicle

An asphalt concrete, heating and heat preservation technology, applied in concrete transportation, road, road repair, etc., can solve pollution and other problems, achieve the effects of low thermal failure rate, optimized heat preservation design, and large-scale construction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

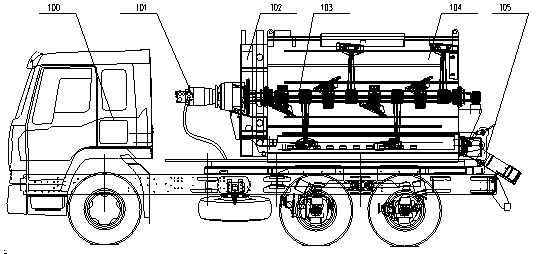

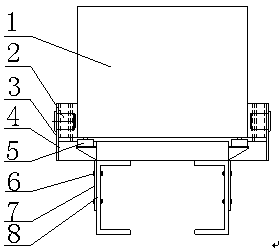

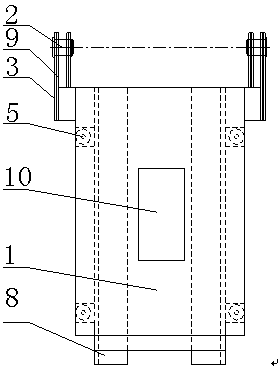

[0031] like Figure 1-7As shown, an asphalt concrete regenerative heating insulation mixing transport vehicle includes a vehicle body 100, an asphalt regeneration heating device, and an emulsified asphalt spraying device 106. The asphalt regeneration heating device is installed on the chassis of the vehicle body, and the asphalt regeneration heating The device includes a mixing tank 1, the top of the mixing tank is provided with a feeding port 10, and the rear part is provided with a discharge port 105. The asphalt regeneration heating device also includes a hydraulic power system 101, a swing arm stirring system 103, a heating and heat preservation system 104, and an asphalt regeneration heating device. Pumping syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com