Concrete mixing truck with lifting device

A technology of mixing transport vehicles and lifting devices, which is applied in the direction of concrete transportation, unloading devices, clay preparation devices, etc., can solve the problems of short transportation distance of dump trucks, easy wear and tear of mixing devices, and high unloading residual rate, so as to improve efficiency , reduce the residual rate and prolong the life of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

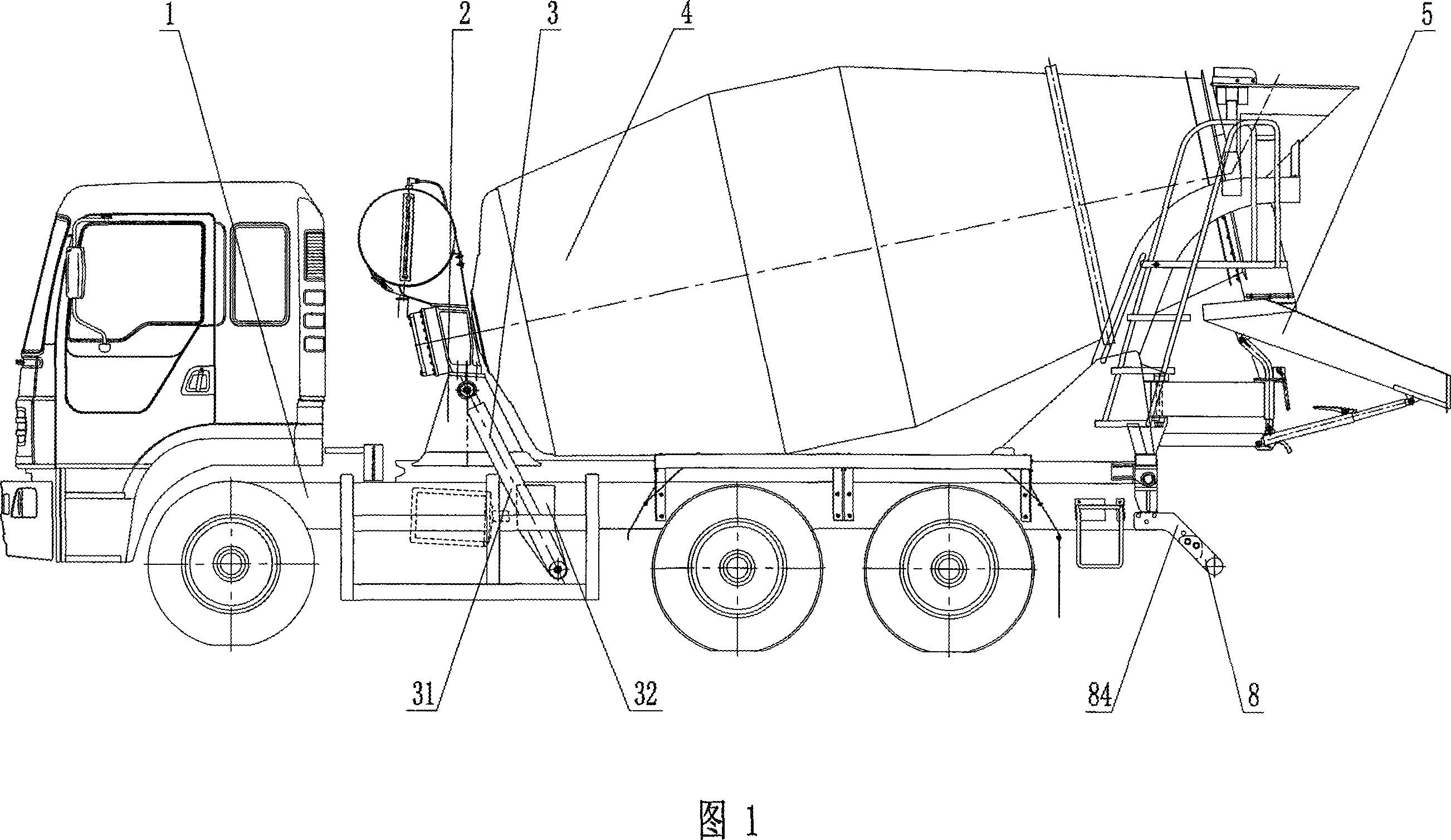

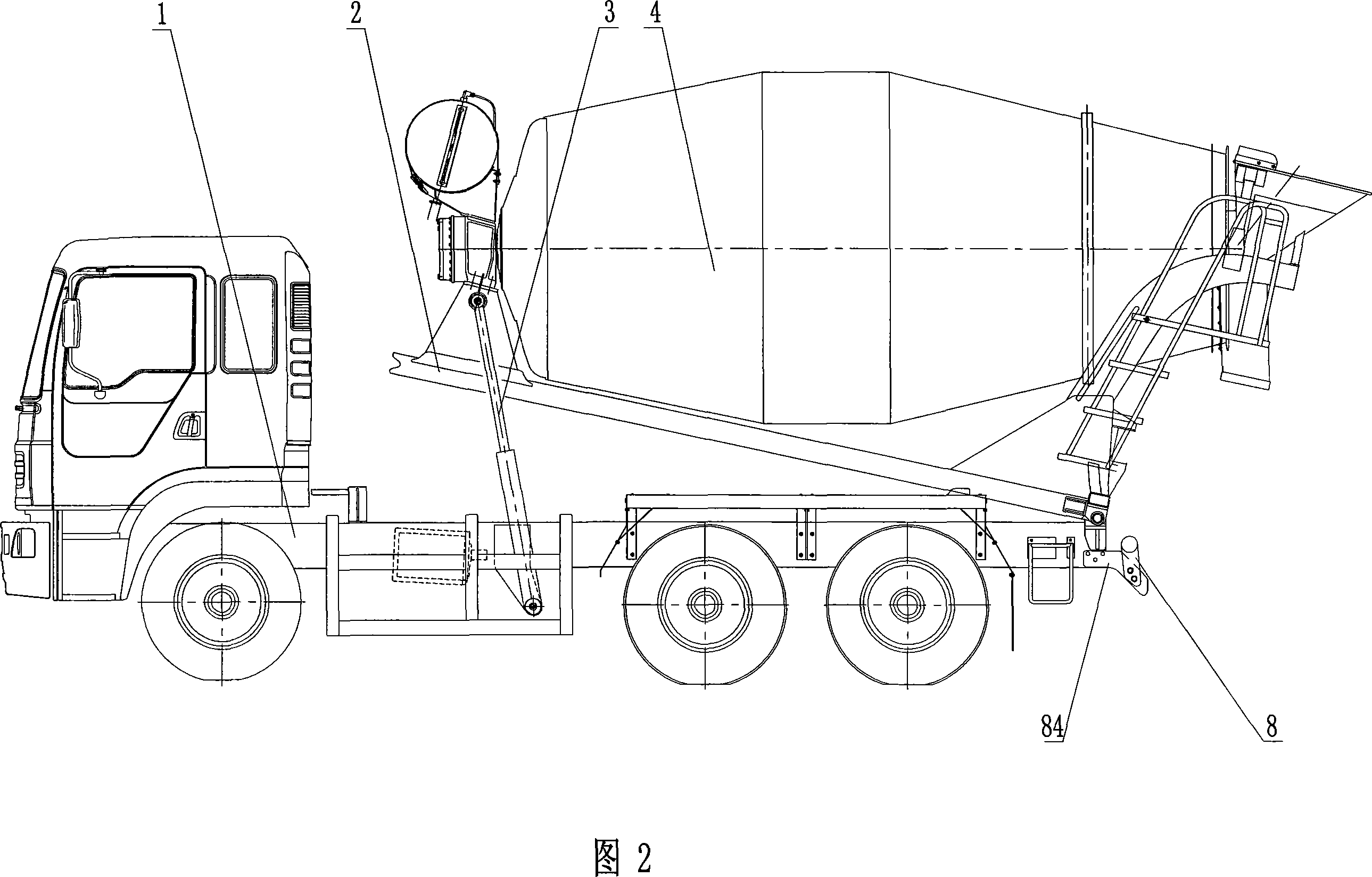

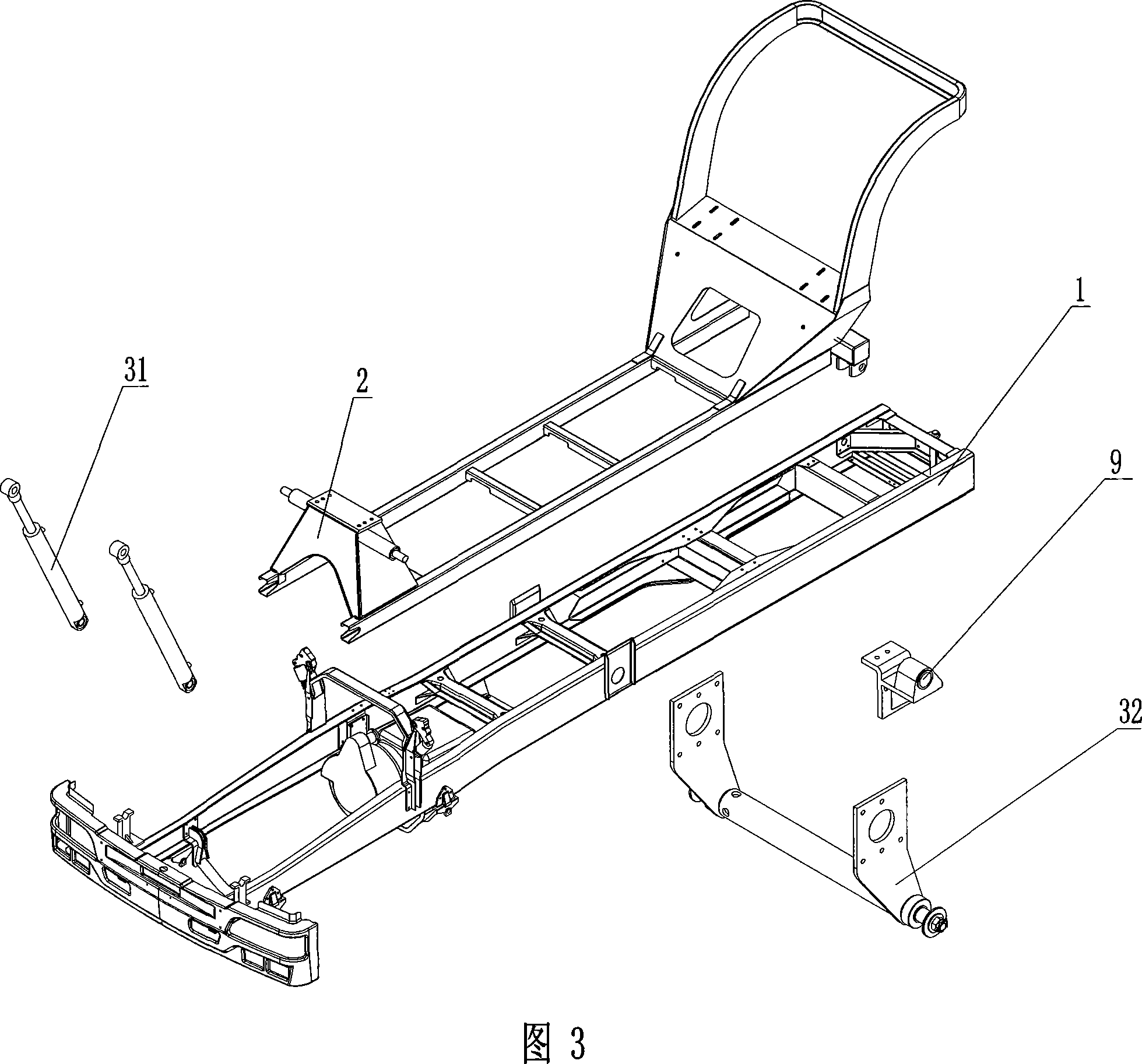

[0031] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the concrete mixer truck with lifting device of the present invention includes a chassis 1, a subframe 2 and a mixing drum 4, and the mixing drum 4 is supported on the subframe 2 Above, the tail of the chassis 1 is provided with an overturning support 9, the tail of the sub-frame 2 and the tail of the chassis 1 are hinged through the overturning support 9, and the front end of the sub-frame 2 is equipped with a lifting device 3, which includes a lifting device 3. Lift oil cylinder 31 and oil cylinder support 32, the two ends of oil cylinder support 32 are installed on the chassis 1, two lifting oil cylinders 31 are respectively located at the both sides of oil cylinder support 32, lift oil cylinder 31 one end and oil cylinder support 32 Hinged, the other end is hinged with subframe 2. In this embodiment, the lifting device 3 adopts the form of double lifting oil cylinders, so that the subframe 2 and the mixing drum 4 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com