Precast concrete carrier vehicle

A prefabricated concrete and transport vehicle technology, which is applied in concrete transportation, construction, building construction, etc., can solve the problems of high labor intensity, low work efficiency, human and financial resources consumption, etc., and achieve automatic operation, safe and reliable use, and reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below through specific embodiments.

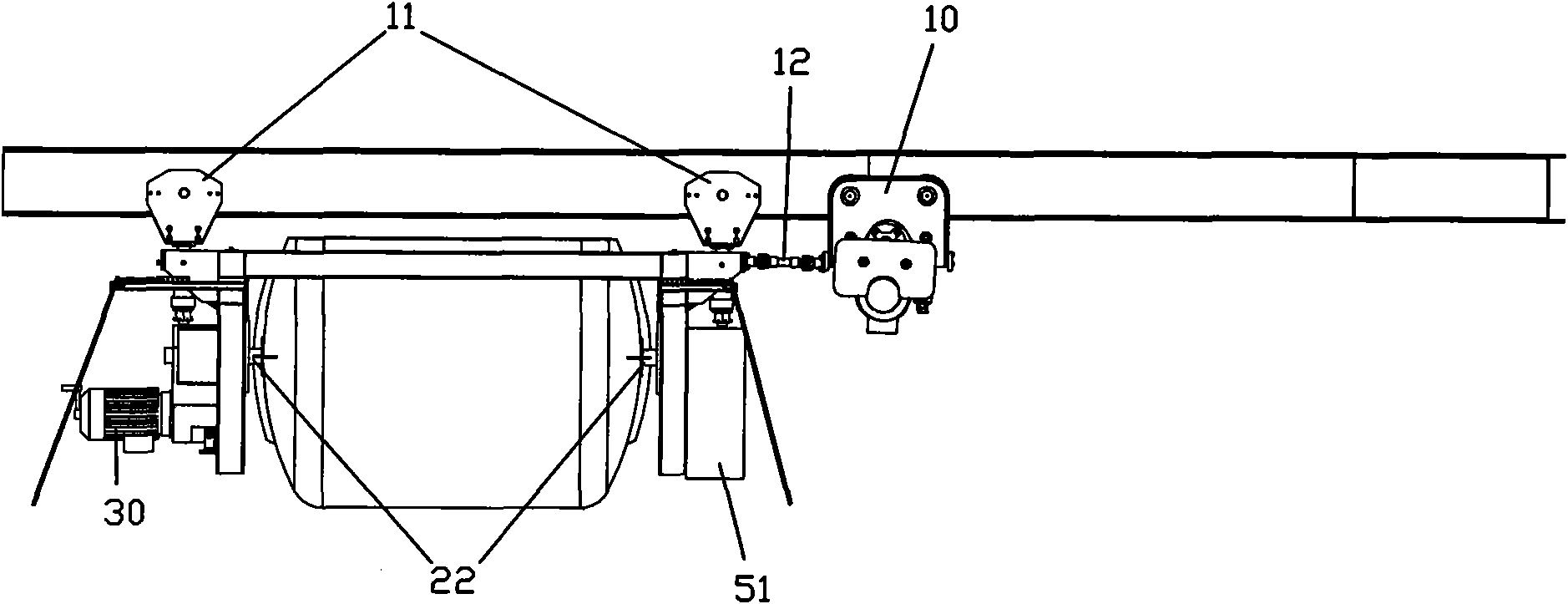

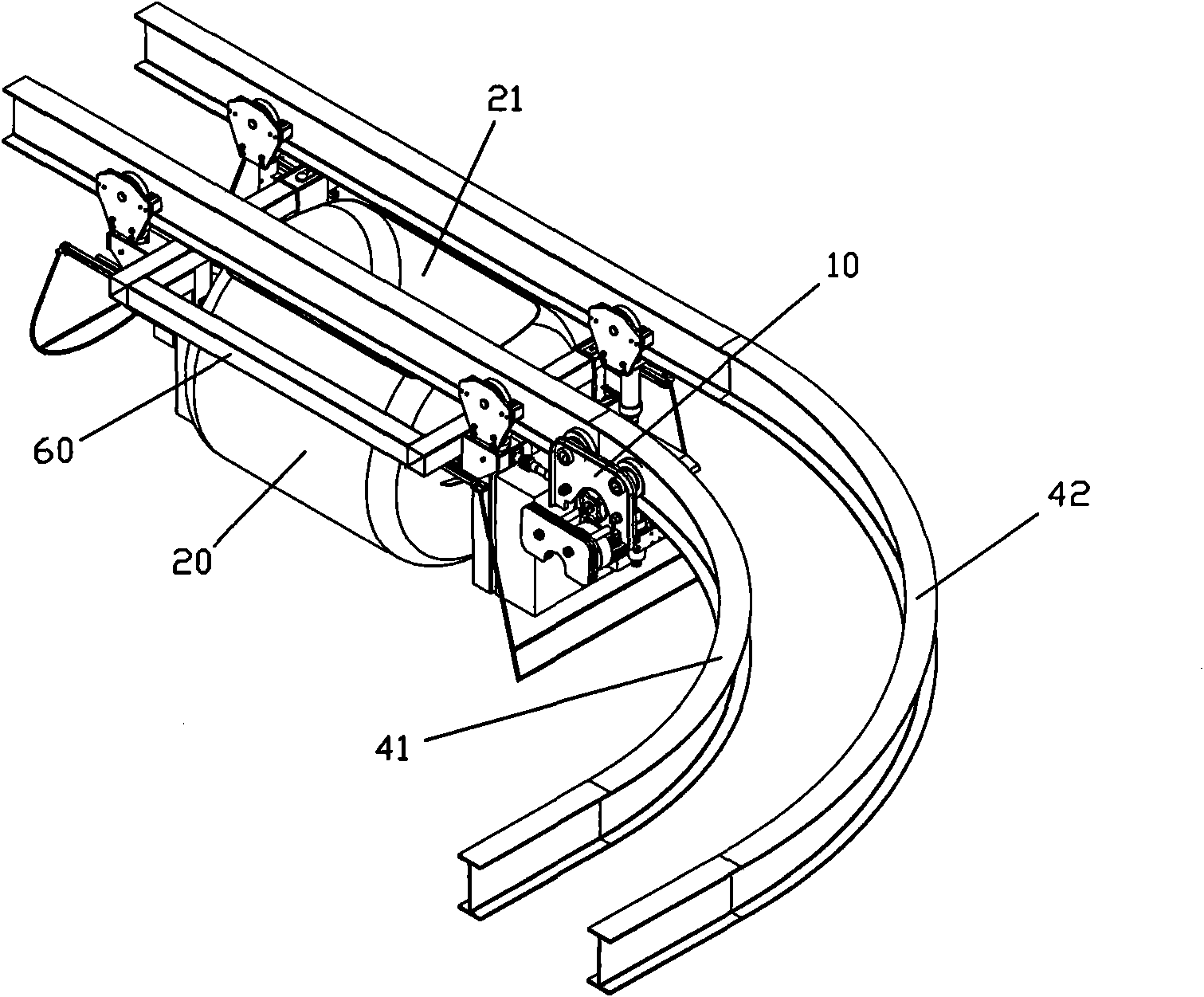

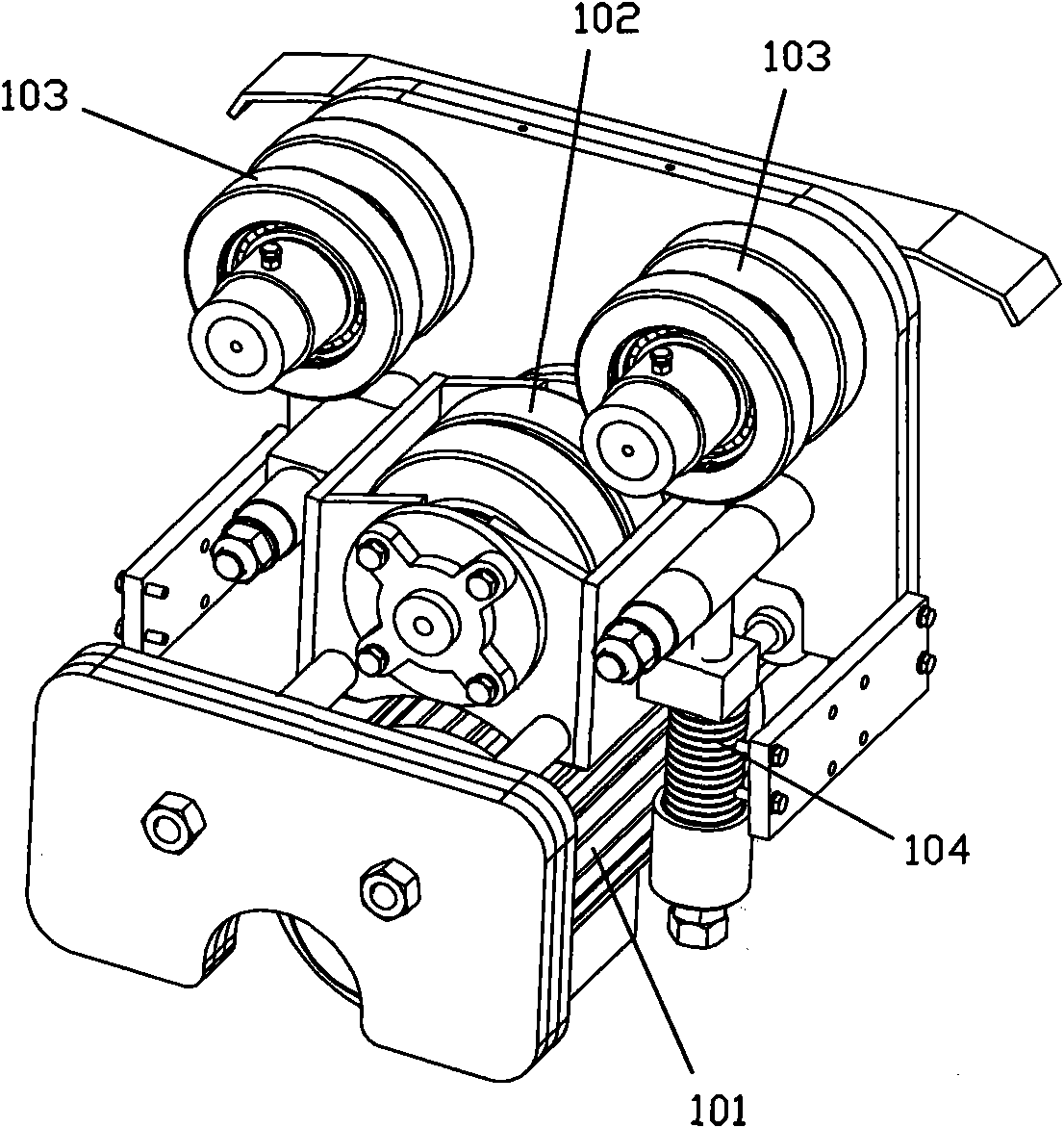

[0037] refer to figure 1 with figure 2 , a prefabricated concrete transport vehicle of the present invention includes a traveling mechanism, a silo mechanism, a silo dumping power mechanism, a track mechanism, an electrical control mechanism and a support mechanism. The running mechanism includes a traction locomotive 10 and a bucket driven wheel unit 11, which is connected with a universal joint 12 between the traction locomotive 10 and the bucket driven wheel unit 11, so that the traction and carrying functions of the transport vehicle of the present invention Modularization is realized, the interface is common and can be quickly interchanged, and the production will not be affected during maintenance. The silo mechanism includes a cylinder 20 with a material inlet and outlet 21 on the upper side, and two ends of the cylinder 20 are provided with support shafts 22 for supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com