Horizontally-arranged self-sealed stirring and transporting vehicle

A mixer truck, self-sealing technology, which is applied in concrete transportation, cement mixing device, clay preparation device, etc., can solve problems such as restricting the development of concrete mixer trucks, low carrying capacity, weak driving stability and safety, etc. problems, to achieve the effect of improving operability, large production workload, driving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

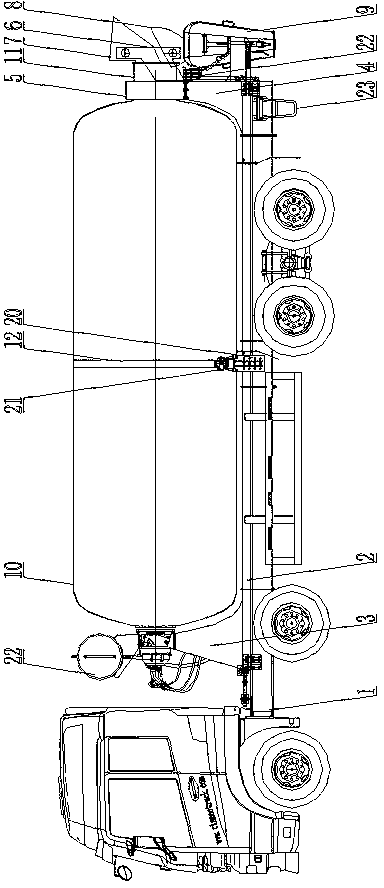

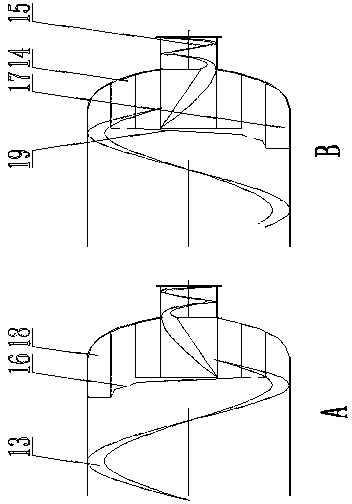

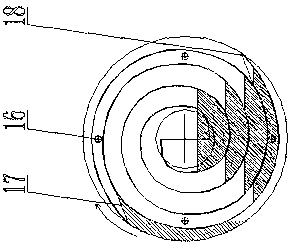

[0038] Such as figure 1 The shown agitator truck with tanks arranged horizontally includes a car chassis 1, a sub-frame 2 installed on the car chassis, a cleaning system 22, and a control system (not shown in the figure). The rear end is provided with a small step ladder 23 (convenient for operators to go up and down and maintain), and the tank body 10 is horizontally arranged on the subframe 2, and the front support 3 is fixed on the subframe 2, and the front support 3 is fixed with Hydraulic motor reducer assembly, the output axis of the hydraulic motor reducer assembly is set horizontally, the output end is fixedly connected with the tank body 10 through the flange, the middle part of the tank body 10 is provided with a ring raceway 12, and the two sides of the subframe are provided with There is a wing support frame 20, and the support roller 21 is fixed on the wing support frame 20. The rear part of the tank body 10 is provided with an inlet and outlet conduit 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com