Reflow backwashing mechanism for automatic filtration of fluid

An automatic filtration and fluid technology, which is applied in the direction of filtration and separation, dispersed particle filtration, fixed filter element filter, etc., can solve the problems affecting the stability of the rotation frequency of the fluid replacement, the low speed of the fluid replacement, and insufficient stability, etc., to achieve Improve the effect of automatic filtering, improve the rotation frequency and work stability and reliability, and the effect of stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

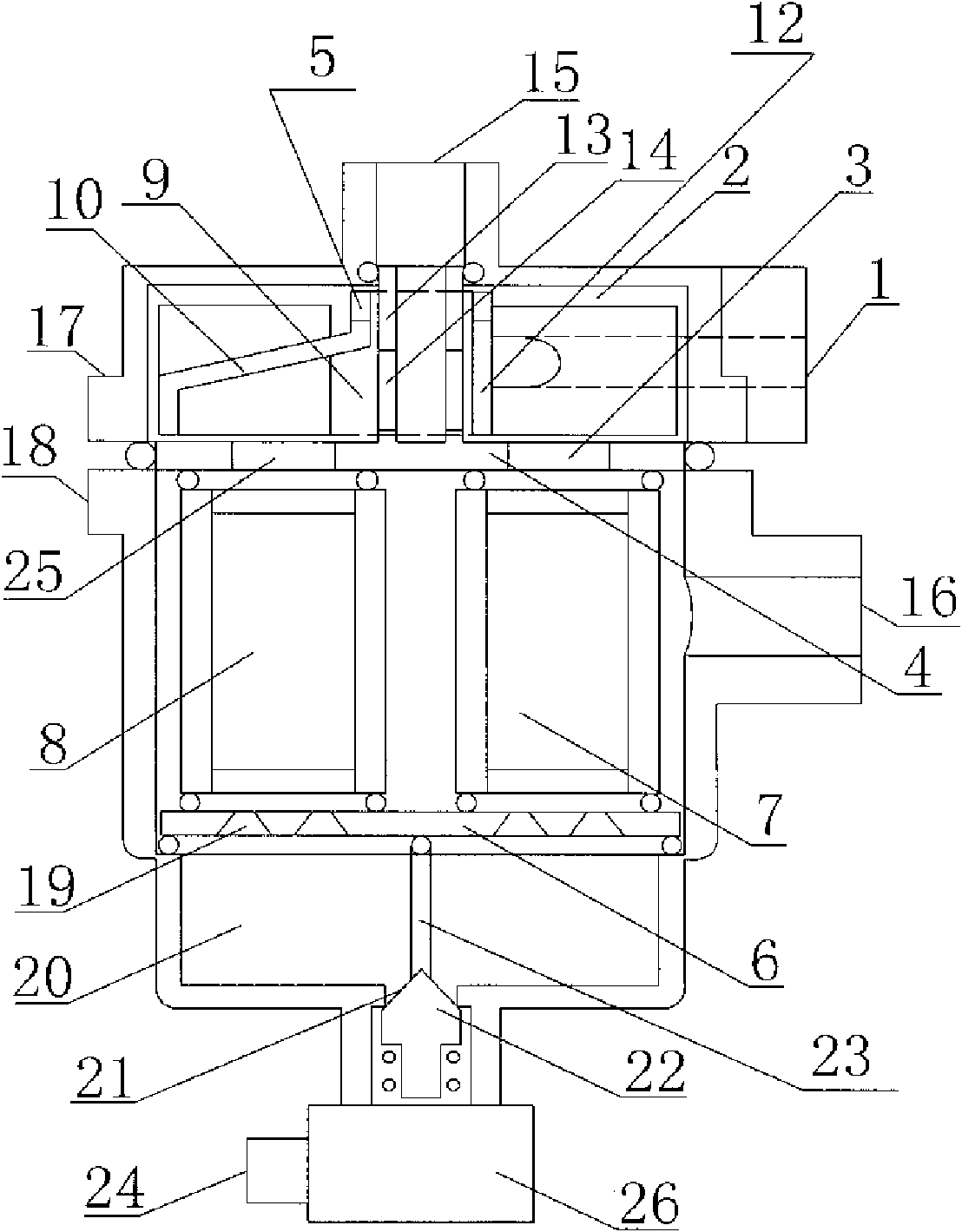

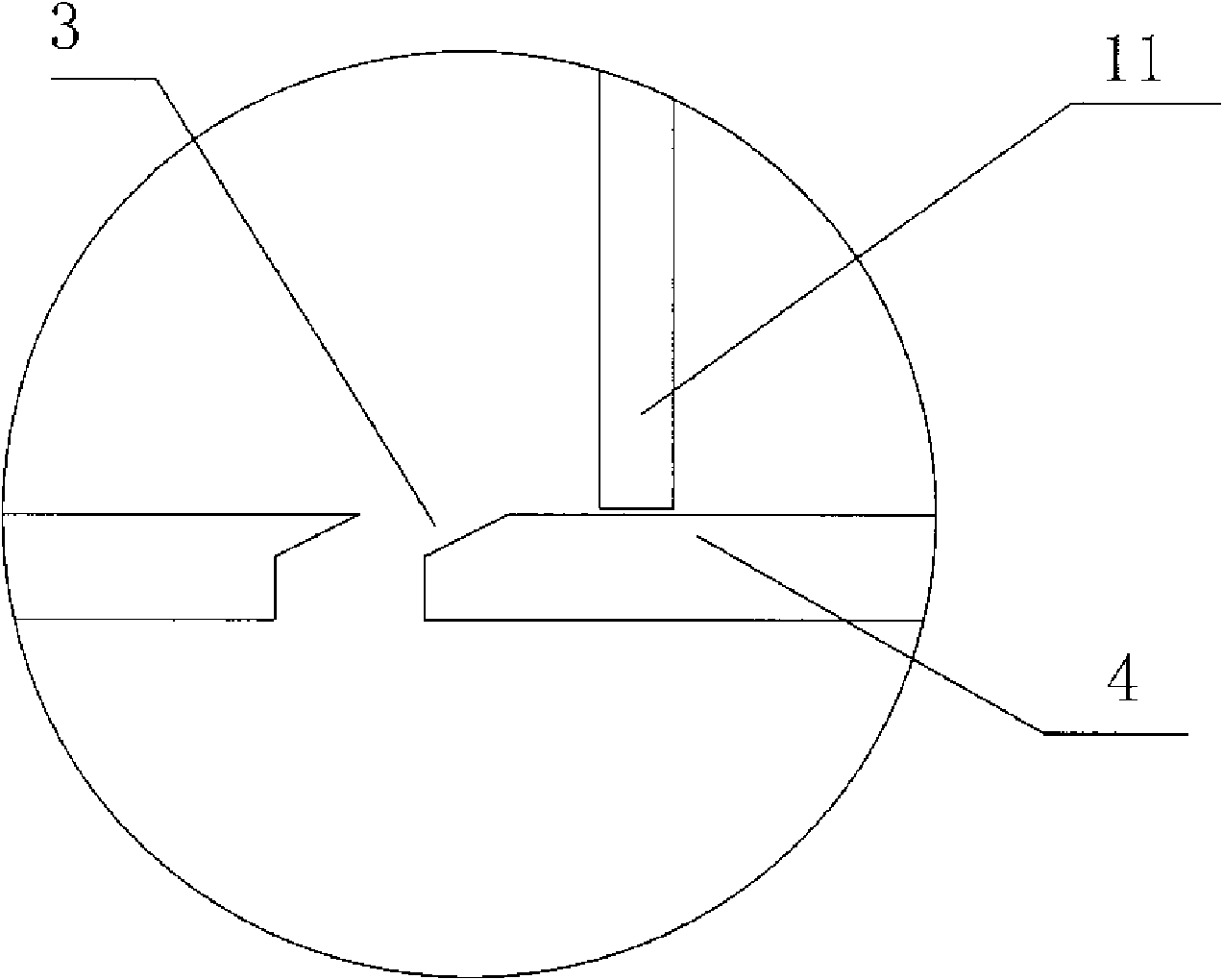

[0011] Accompanying drawing has shown structure of the present invention and embodiment thereof, further describes the relevant details of its embodiment below in conjunction with accompanying drawing: Attached figure 1 A reflux and backwashing mechanism for automatic fluid filtration, including an upper casing 17 and a lower casing 18 installed together, the upper casing 17 has a fluid exchange chamber 2, and the fluid exchange chamber 2 has a A rotatable paddle 11, a baffle 10 and a hollow shaft sleeve 12. The paddle 11 and the baffle 10 are connected with the hollow shaft sleeve 12 as a whole, which is called a replacement fluid. The upper casing 17 includes a return outlet 15 and the tangentially arranged fluid inlet 1, because the inlet 1 is arranged tangentially, the tangential impulse of the fuel can generate the maximum torsional moment, which impacts the blade 11, and an upper partition is arranged inside the upper casing 17 and the lower casing 18 4. The upper partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com