Circuit substrate, manufacturing method thereof, display substrate and splicing display device

A technology for circuit substrates and manufacturing methods, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of poor processing performance of glass substrates, easy wear and tear of conductive connections, and reduced product reliability, and achieves water and oxygen corrosion resistance. Good performance, improved service life and reliability, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to further illustrate the circuit substrate, the manufacturing method thereof, the display substrate, and the spliced display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

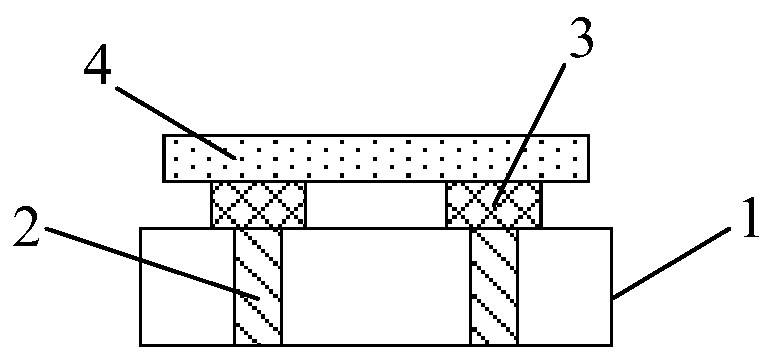

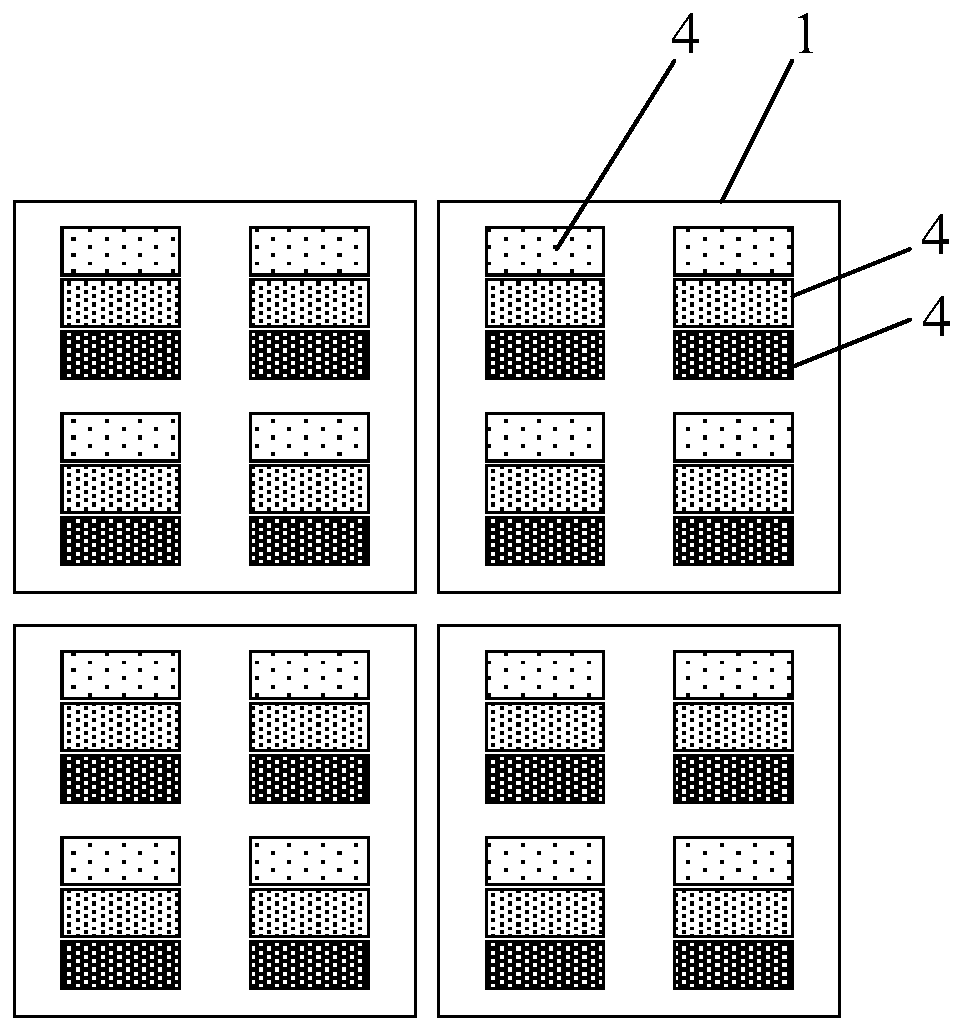

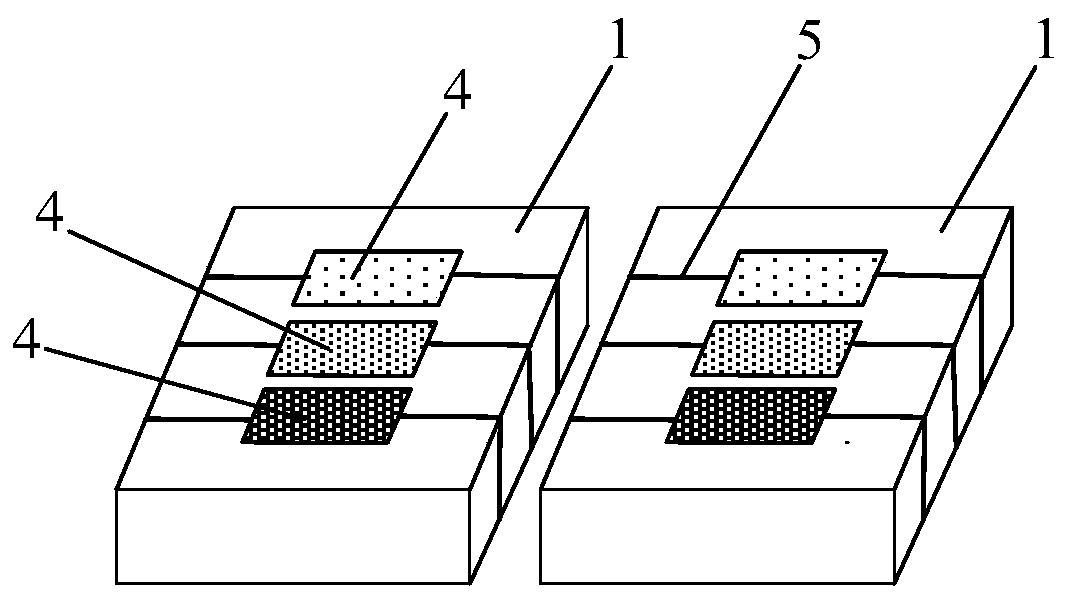

[0063] Based on the problems in the background technology, the inventors of the present invention have found through research that when using a glass substrate, such as figure 1 and figure 2 As shown, it can be considered to form via holes on the glass substrate 1 first, then form Cu pillars 2 by electroforming in the via holes, and form pads 3 on the Cu pillars 2, and finally micro light emitting diodes 4, such as Micro LED Or the mini LED is mounted on the pad 3. Although this method can ensure that the formed via hole has good conductivity when the glass substrate is used, there are still two main problems in this method that are difficult to overcome in practical applications. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com