Permanent-magnetic clutch device

A clutch device, permanent magnet technology, applied in the main field of rotational force between driven shafts, engagement and separation, can solve the problems of slow engagement and separation speed, easy short circuit of the circuit, uneven engagement of friction plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

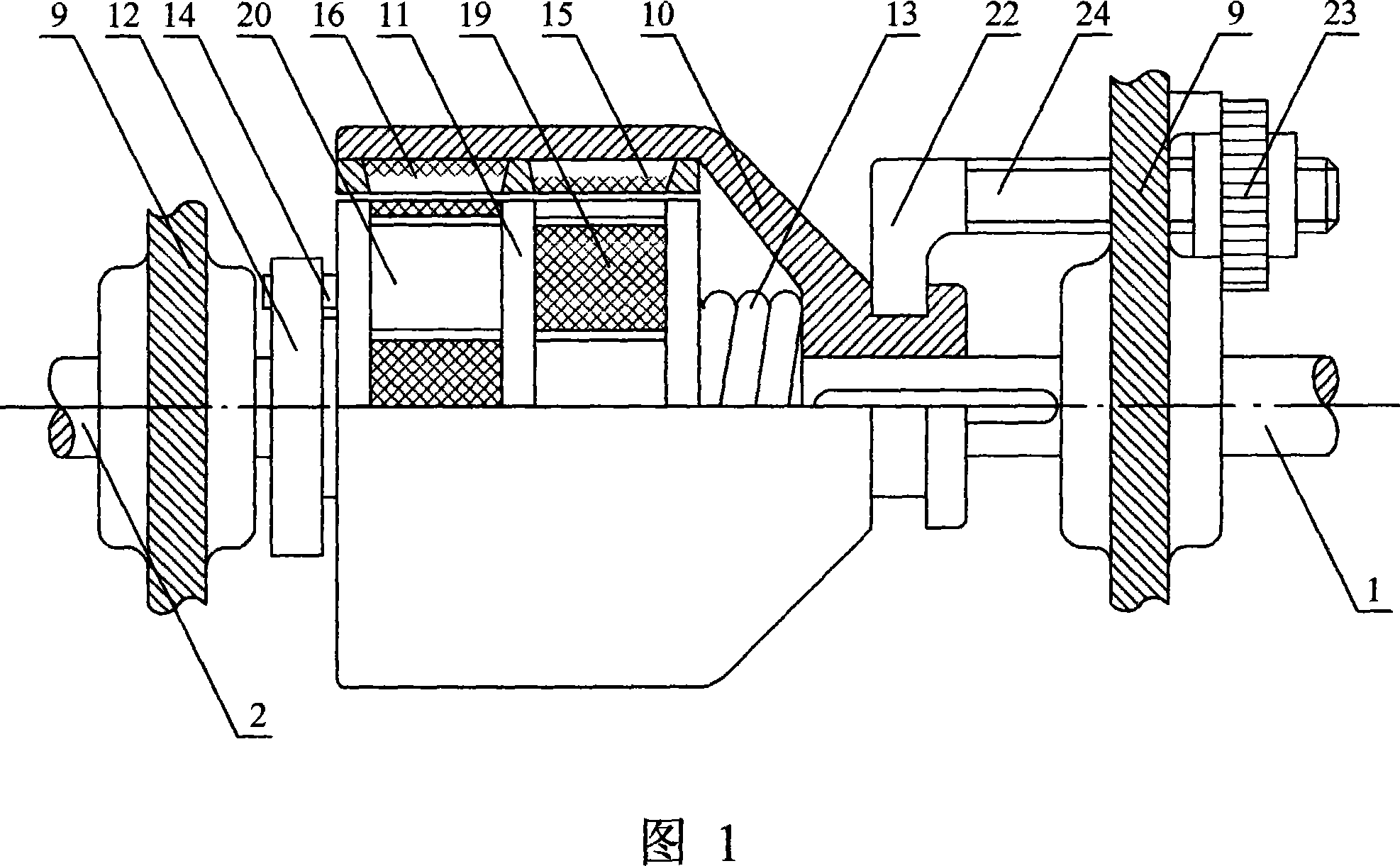

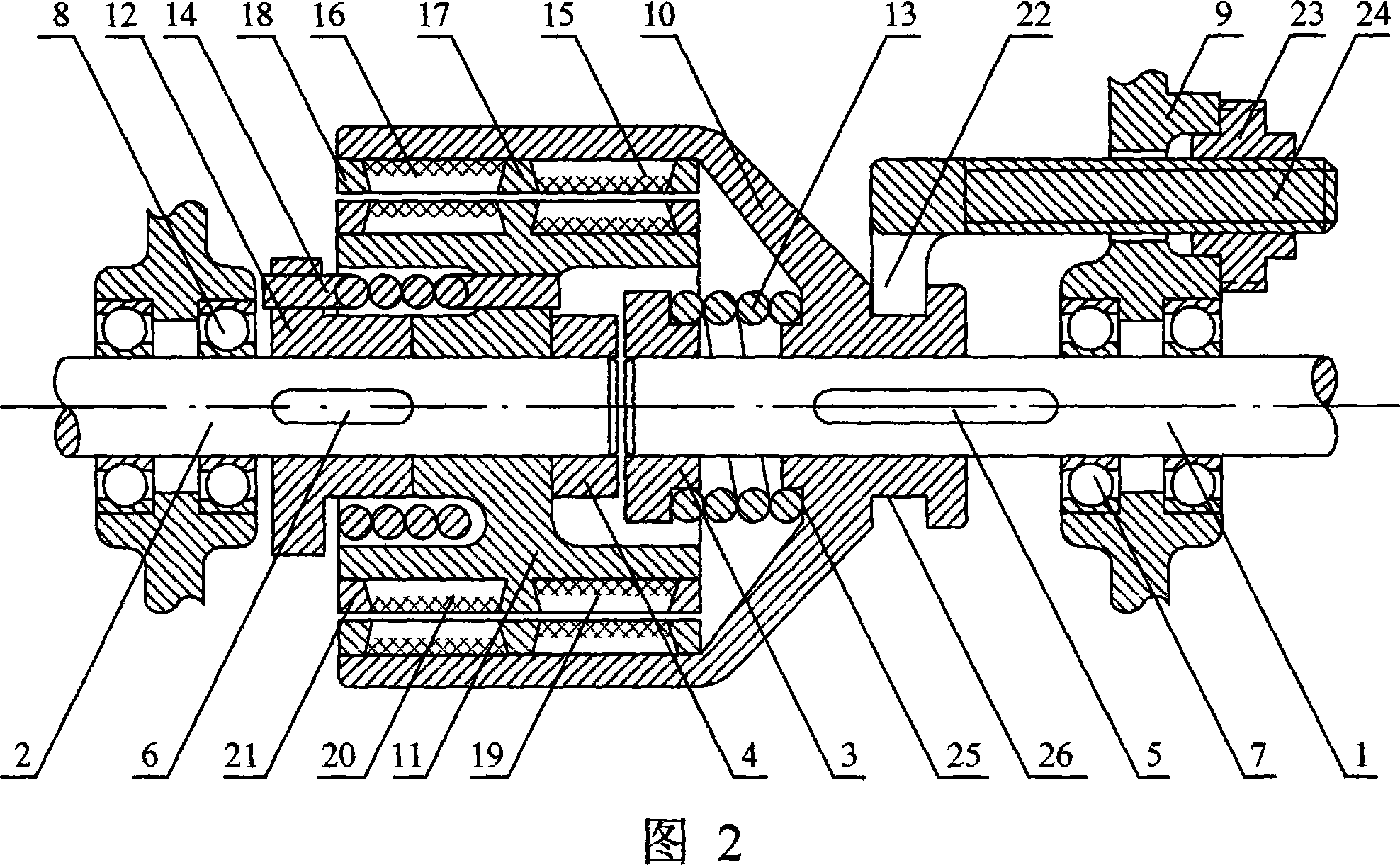

[0056]Embodiment 1: As shown in Figure 1-2, the driving shaft (1) and the driven shaft (2) of the present invention are aligned. The driving wheel (10) and the driving shaft (1) are guided by the driving shaft key (5) and can be connected for axial movement, and its moving distance is less than the axial length of a single magnetic block. The active inner and outer magnetic blocks (15, 16) are radially connected with the inner wall surface of the cylinder of the active wheel (10). The middle and side hoops (17, 18) of the active magnetic block press the magnetic block between the axial active inner and outer magnetic blocks (15, 16) and the edge respectively, and are tightly connected with the driving wheel disc (10). The section is trapezoidal. The active spring (13) is a helical compression spring. One axial end of the spring is placed on the active shaft cap (3), and the other end is placed on the spring groove (25) of the active wheel. The maximum compression force of the...

Embodiment 2

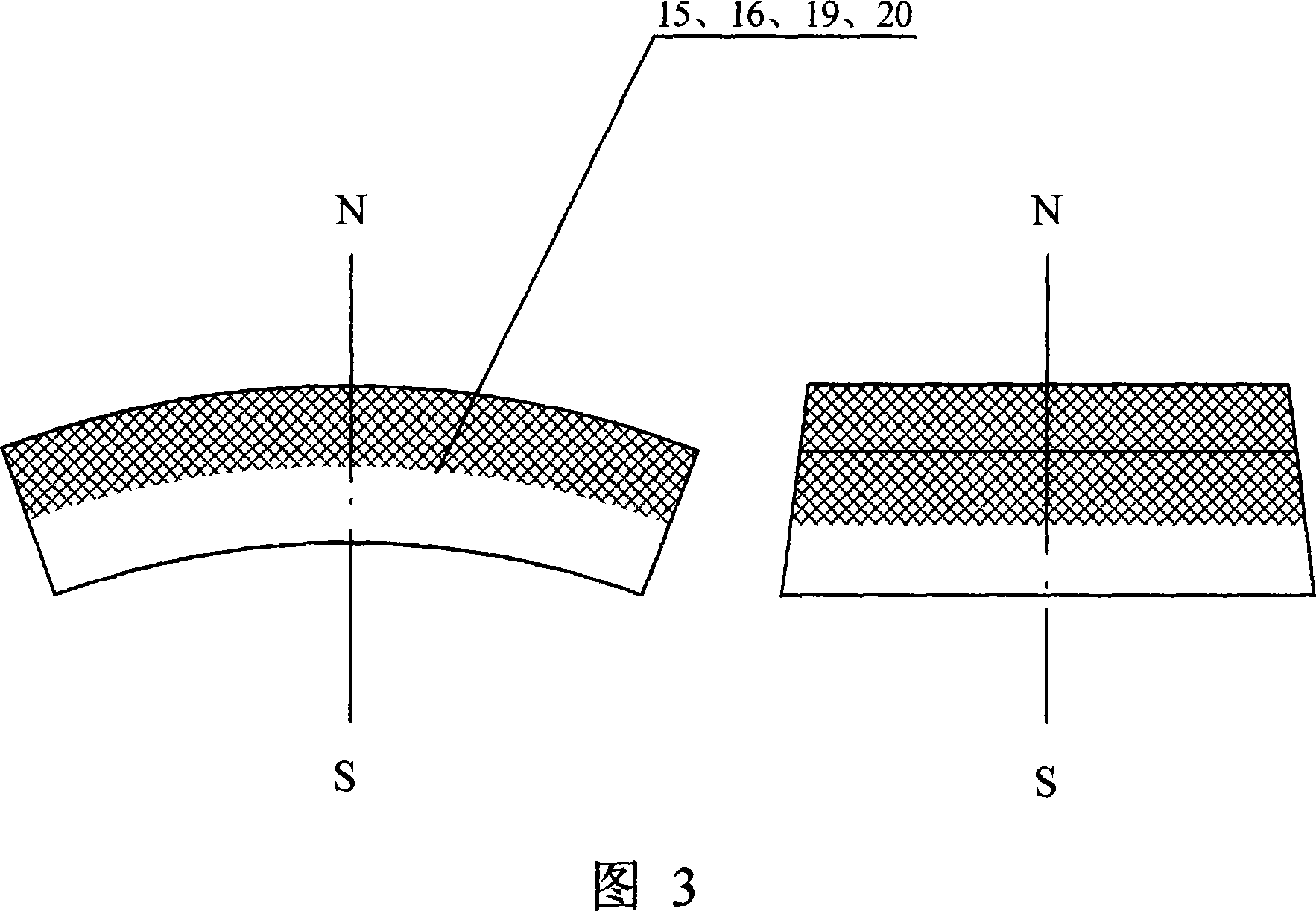

[0057] Embodiment 2: as shown in Figure 3, the main and driven inner and outer magnetic blocks (15, 16, 19, 20) of the present invention are permanent magnet tile-shaped structures, and the outer arc surface and inner arc surface direction of the magnetic block are south poles (S) The magnetization direction of the north pole (N), the arc direction section of the magnetic block is trapezoidal, and the trapezoidal direction of the active magnetic block and the driven magnetic block are in opposite directions. The magnetic block is made of high-performance permanent magnets, and made into a flat block shape to reduce the radial size of the device.

Embodiment 3

[0058] Embodiment 3: as shown in Figure 4, the inner circle of the control wheel (23) of the present invention is a thread, the outer circle is an axial straight line, the outer circle of the joystick (24) is a thread, and the rod head is formed into two pieces. The control dial (22) is fastened and connected, and the connection method can be bolts, rivets or welding. The control wheel (23) can be rotatably connected with the joystick (24), and the control dial (22) is made of non-ferromagnetic material. . Its working principle is: when the control wheel (23) rotates, the joystick (24) is moved axially, and the rotation can control its movement and counteract the axial impact force produced between the main and driven magnetic blocks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com