Rolling crankshaft fillet quick clamping bracket

A crankshaft, fast technology, applied in the direction of grinding workpiece support, clamping, support, etc., can solve the problems of slow operation, high labor intensity, etc., and achieve the effect of reasonable structure, convenient operation and simple manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

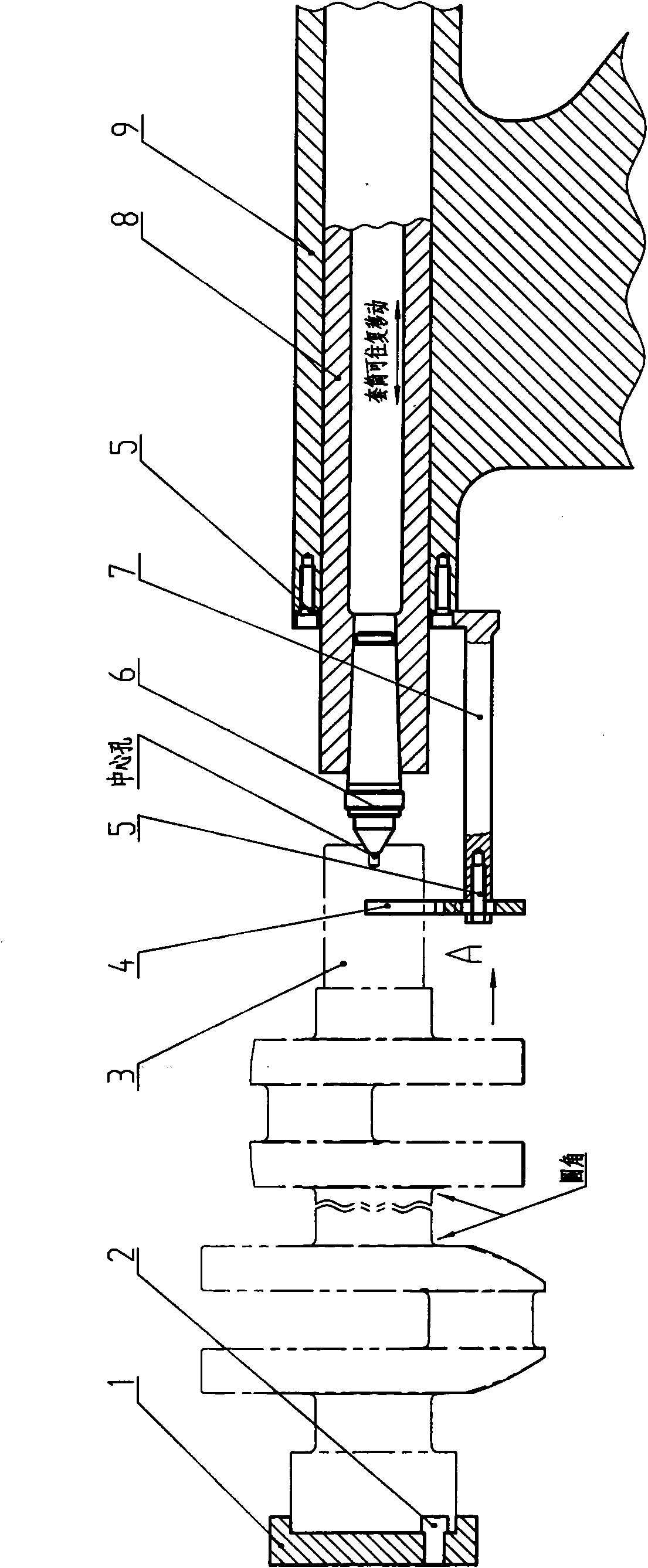

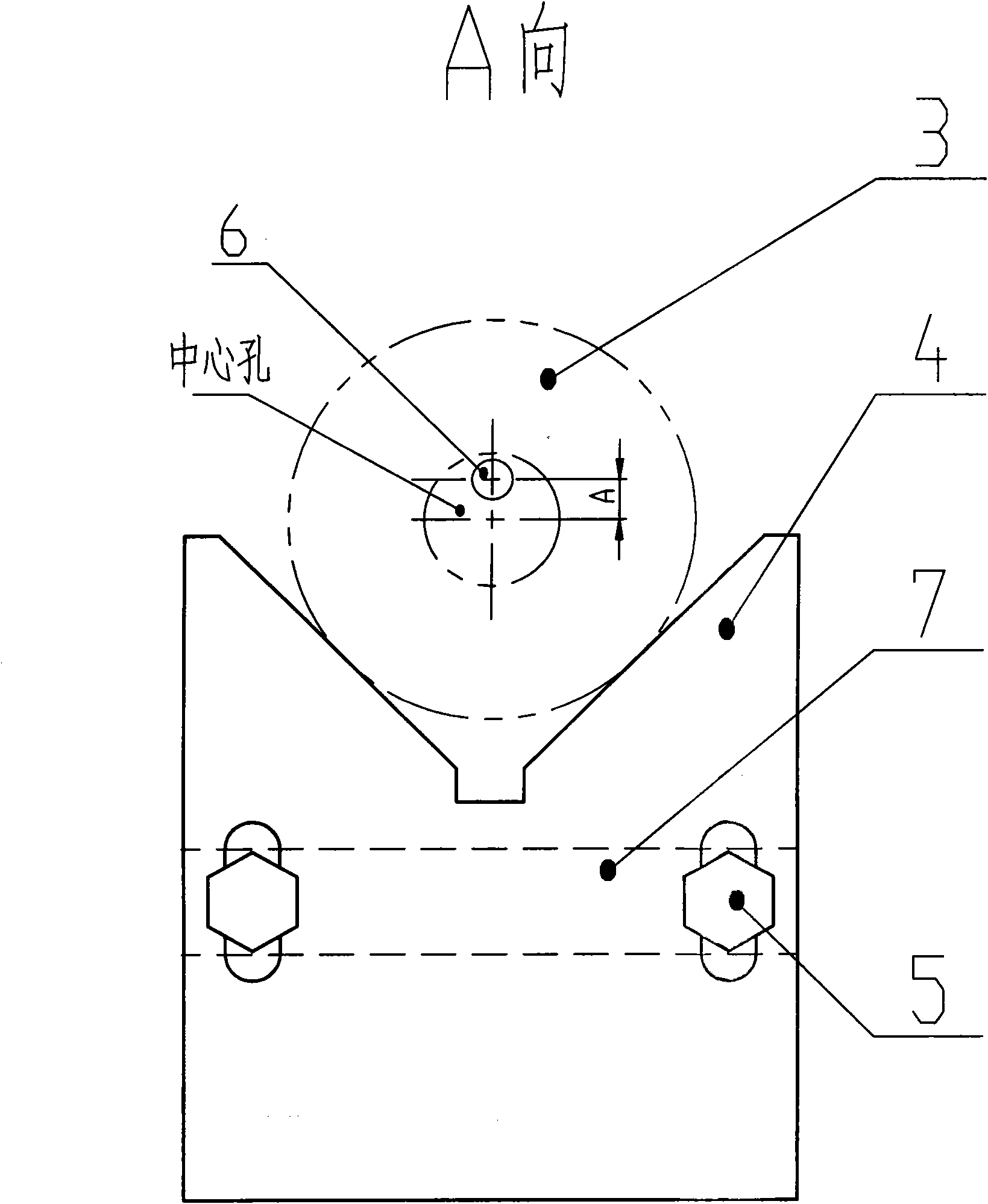

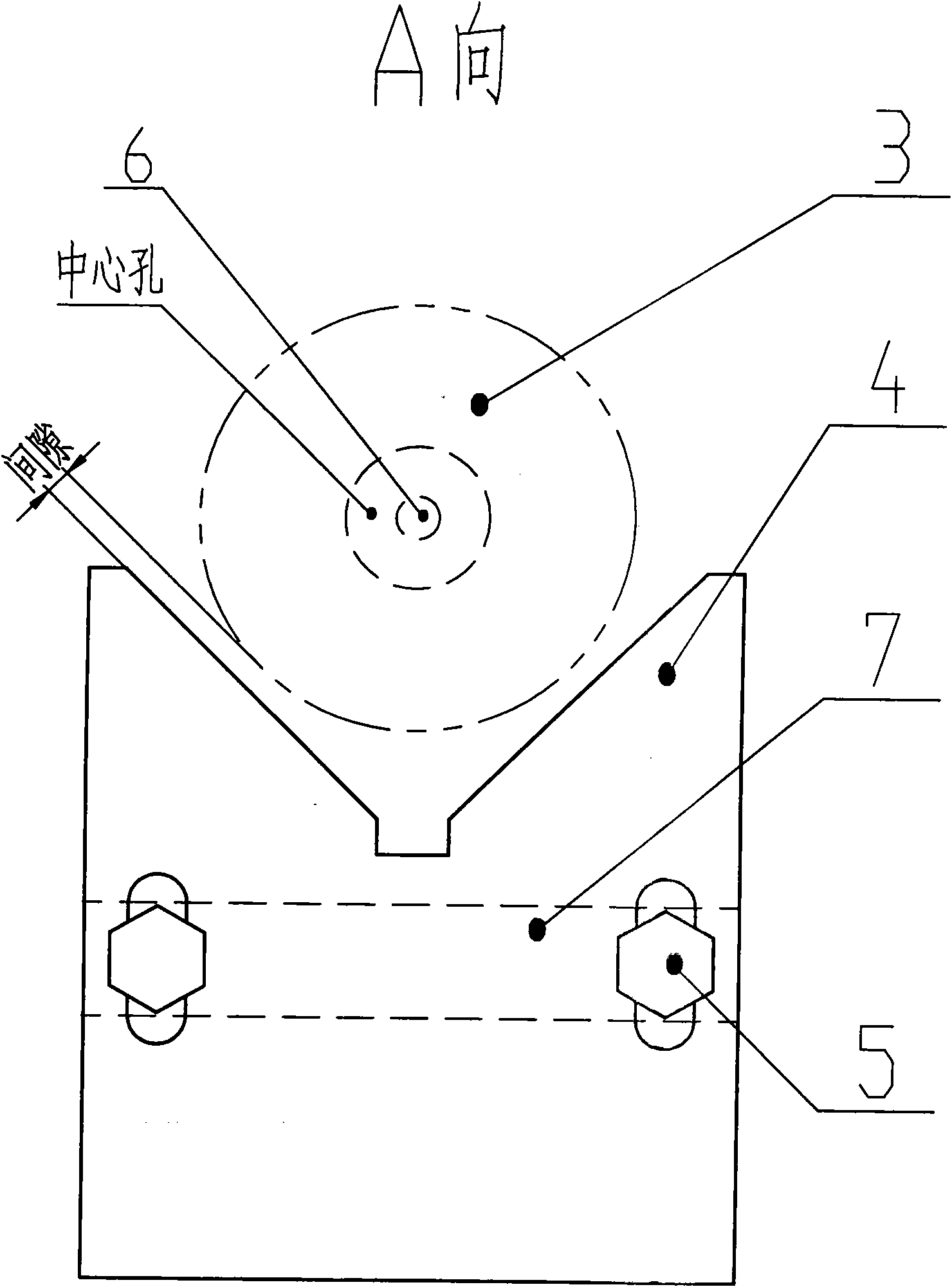

[0014] from figure 1 , figure 2 with image 3 It can be seen from the figure that a rolling crankshaft fillet fast clamping bracket includes drive discs 1 and supporting devices respectively located at both ends of the crankshaft 3 . The crankshaft 3 big end is provided with process location hole, and small end is provided with central hole. Said driving disc 1 is arranged on the big end of the crankshaft 3, on which there is a positioning pin 2 corresponding to the process positioning hole of the big end of the crankshaft, the front part of the crankshaft journal is inserted into the driving disc 1, and the positioning pin 2 is used for circumferential positioning . The driving disc 1 can be fixed on the rotary transmission system of the existing machine tool, driven by the transmission system of the machine tool.

[0015] The supporting device of the present invention is arranged at the small head end of the crankshaft. The supporting device includes a support plate 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com