Crankshaft link hydraulic motor

A hydraulic motor and crankshaft connecting rod technology, applied in the field of hydraulic motors, can solve the problems of short life, high energy consumption, and loud noise of hydraulic motors, and achieve the effect of reducing noise and energy consumption and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

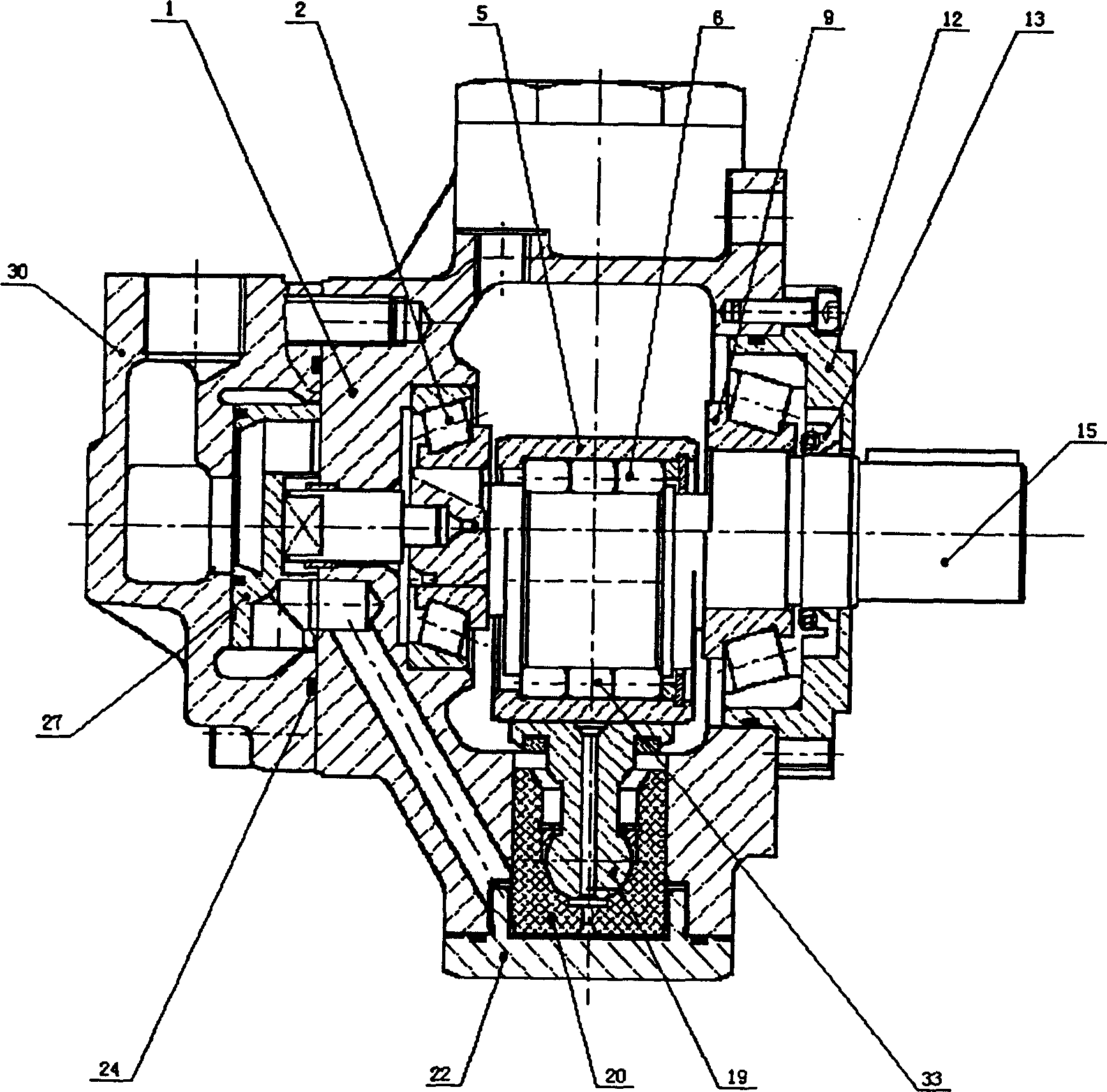

[0008] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

[0009] Such as figure 1 As shown, the oil pan 30 of the crankshaft-connecting rod hydraulic motor of the present invention is fixedly connected with the housing 1 by screws, and a sealing ring 24 is installed therebetween. The oil pan is opposite. On the circumference of housing 1, 5-9 odd-numbered cavities and plunger caps 22 of the same number are evenly distributed radially in the plunger cylinder, and slidable plunger 20 is respectively housed in the plunger cylinder, and the connection between plunger 20 and connecting rod 19 The ball head is connected. The crankshaft 15 is supported by bearings 2 and 9 at both ends, and is fixed in the housing 1 and the front cover 12. The bearings 2 and 9 are respectively arranged in the bearing holes of the housing 1 and the front cover 12. The oil seal 13 prevents oil from seeping through the shaft hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com