Track-torsion connecting bidirectional hard sealing butterfly valve

A kind of hard sealing, butterfly valve technology, applied in the field of orbital torsion connection bidirectional hard sealing butterfly valve, can solve the problem of no bidirectional sealing performance, easy damage to the sealing surface, short service life, etc., to achieve small torque, eliminate friction, improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

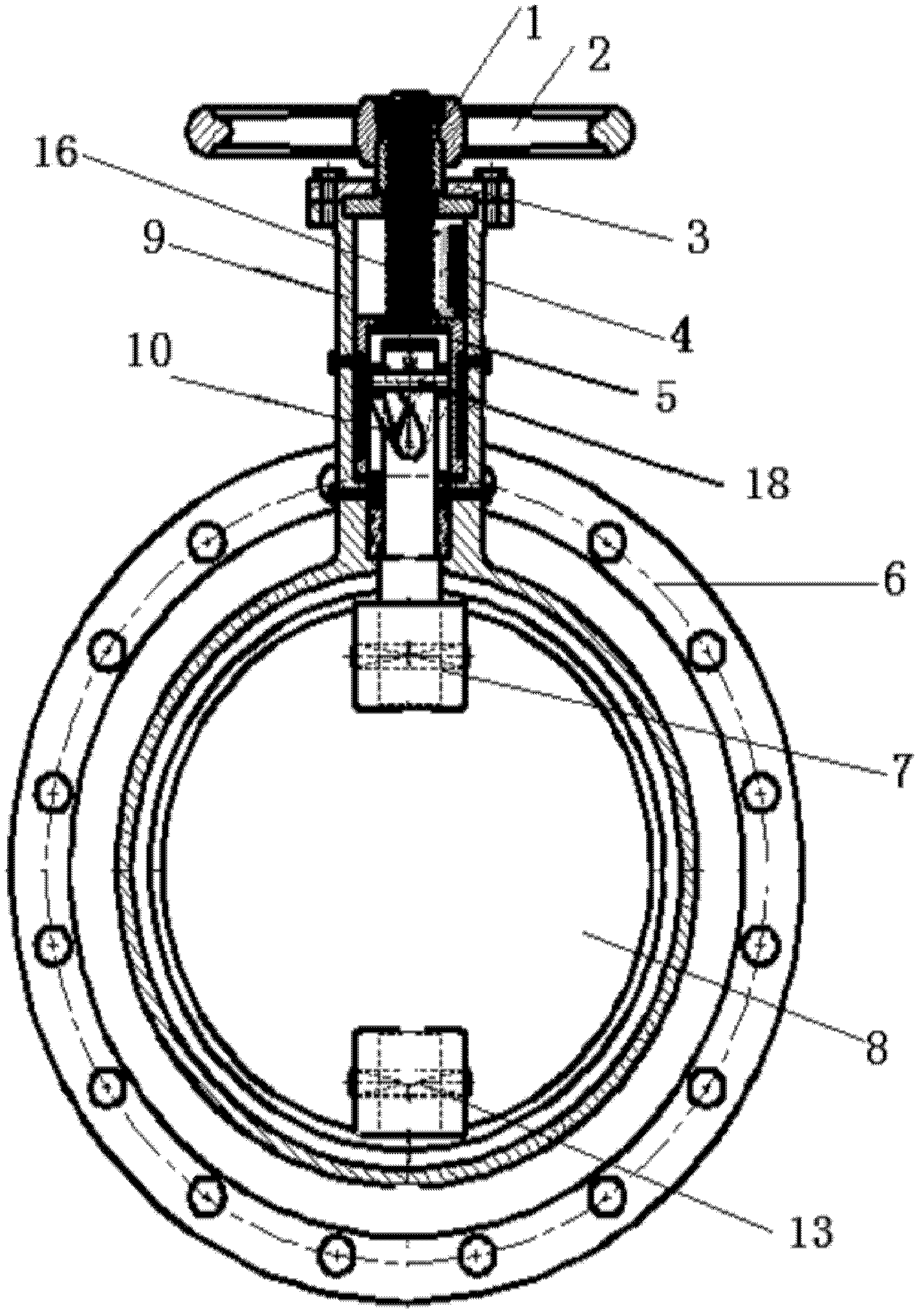

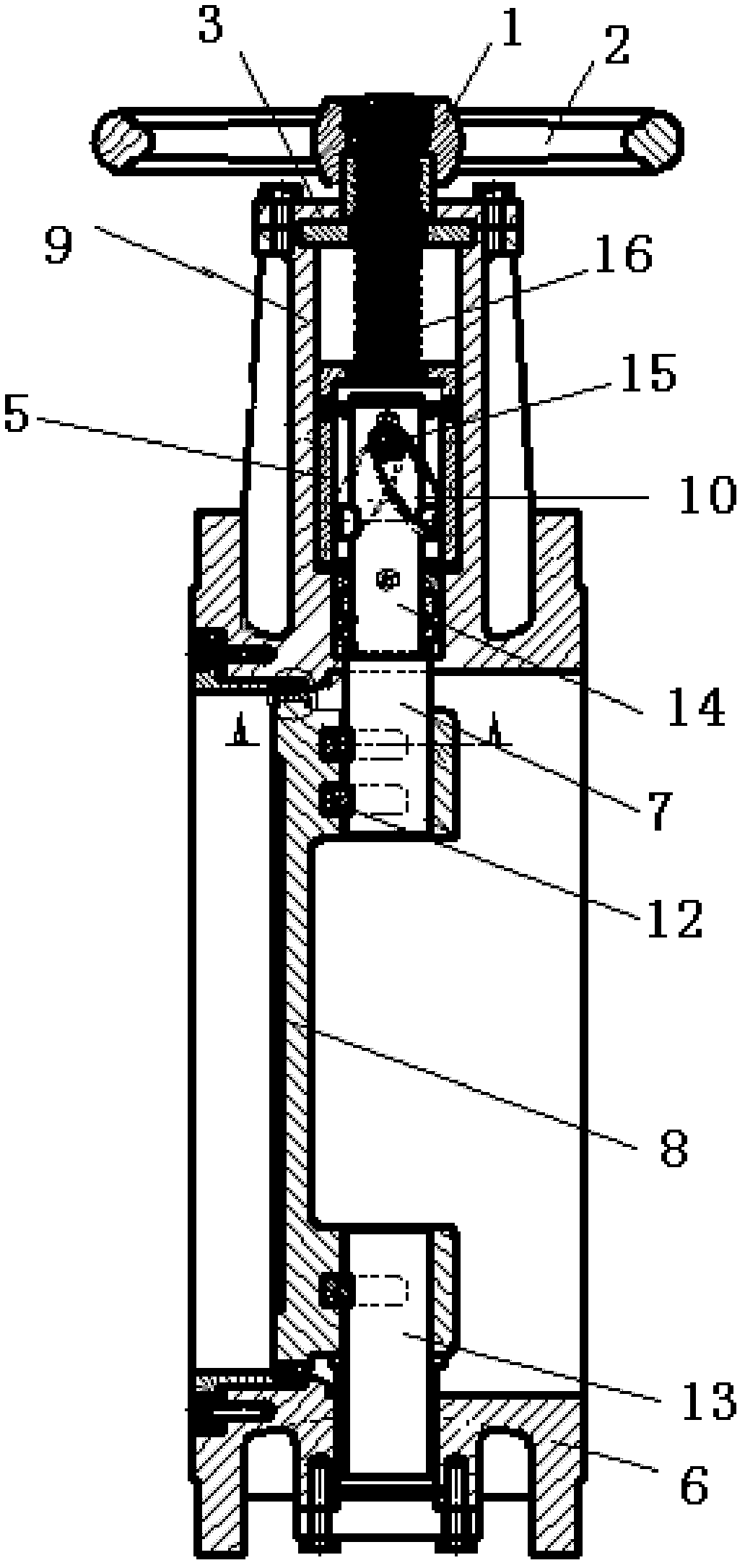

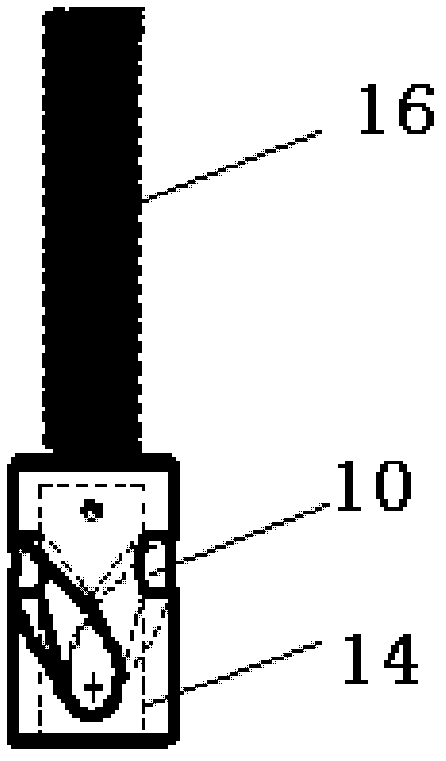

[0020] Such as figure 1 with figure 2 As shown, a two-way hard-sealed butterfly valve with orbital twisting connection includes a valve body 6, a valve plate 8 located in the valve body 6, and a rotating device for controlling the rotation of the valve plate 8. The rotating device for controlling the rotation of the valve plate 8 includes a hand wheel 2, Screw rod 16, and nut 1 matching with screw rod 16, nut 1 and hand wheel 2 are fixed together by stop screw, nut 1 is set on screw rod 16, and nut 1 is fixed on valve body 6 through gland 3 On the rotating sleeve 9 of the rotating sleeve 9, there is a guide sleeve 5 in the rotation sleeve 9, the guide sleeve 5 is fixed on the screw rod polished rod 14 by screws, and the guide sleeve 5 is threadedly connected with the screw mandrel, as Figure 5 with Image 6 As shown, on the guide sleeve 5, there is a through chute 17 along the length direction of the screw rod 16. In order to prevent the guide sleeve 5 from rotating togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com