Direct driving type dual spindle accurate rotating platform

A direct-drive, precise technology, used in large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of large friction of the worm gear and worm of the transmission chain, affecting the transmission accuracy, and long transmission path, so as to improve the positioning accuracy. and repeatable positioning accuracy, simple manufacture and installation, and convenient connection adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

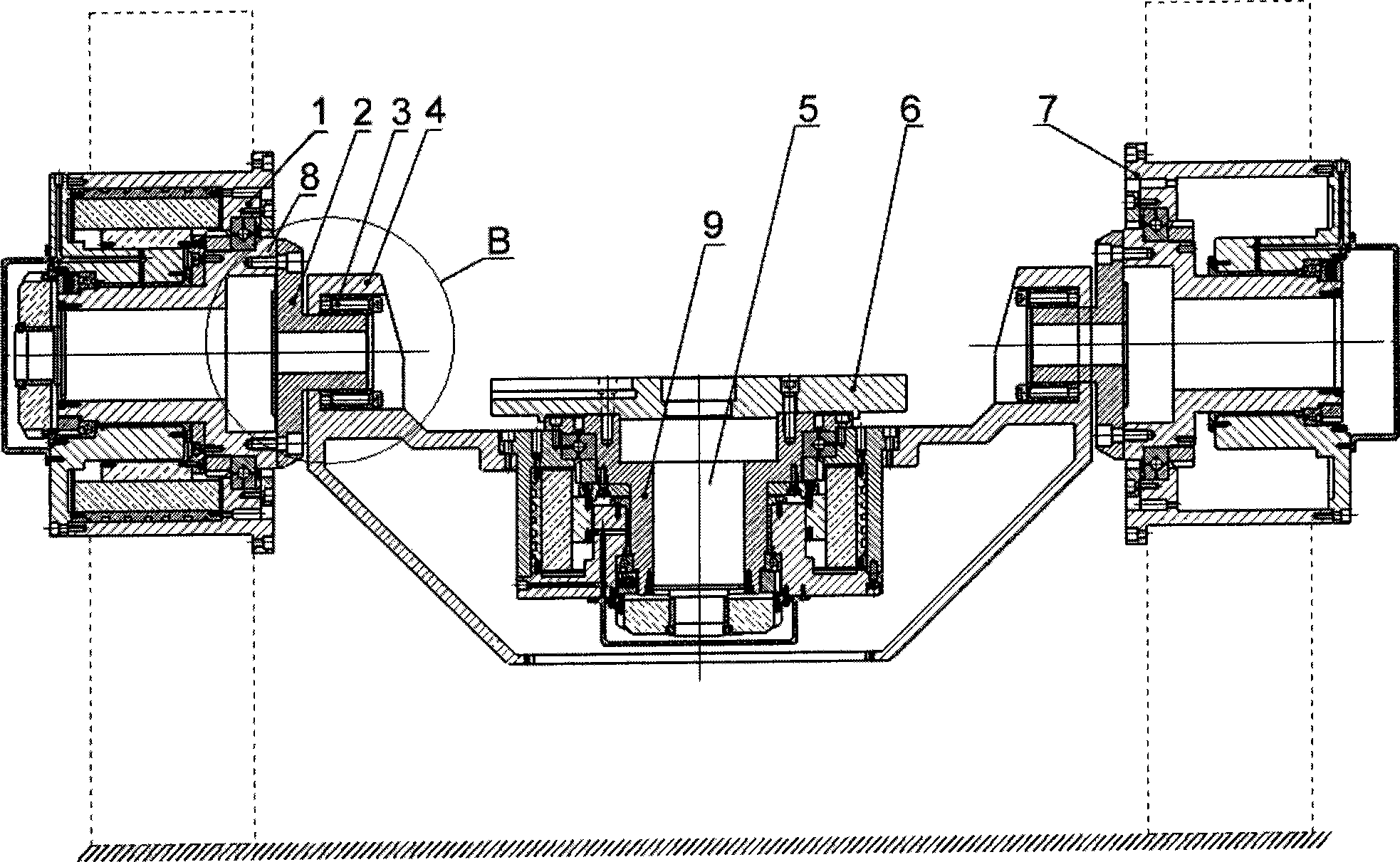

[0016] Example: such as figure 1 As shown, a direct-drive double-axis precision turntable includes an A-axis torque motor 1 , a C-axis frame 4 , a C-axis torque motor 5 , a workbench 6 , and a bearing seat 7 .

[0017] The A-axis torque motor 1 and the bearing block 7 are identical in appearance and structure, and are respectively installed on the machine tool (as on both sides of the gantry column of the gantry frame).

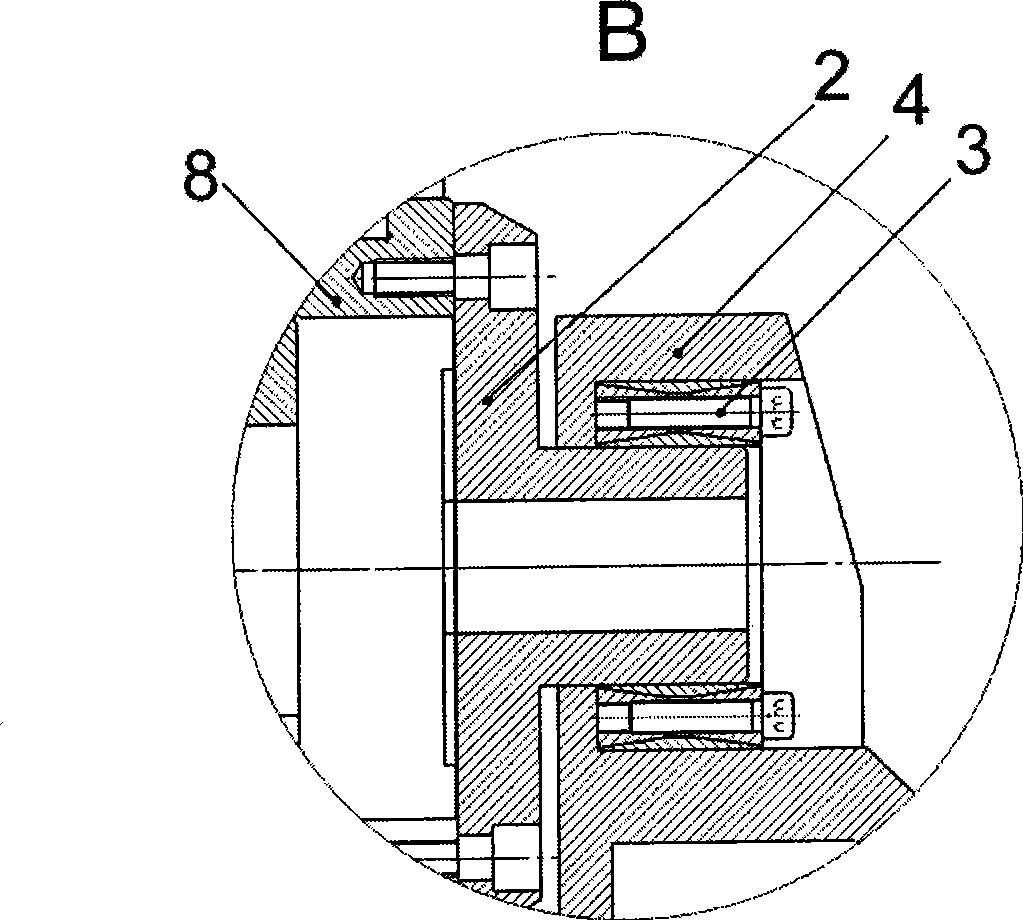

[0018] One side of the C-axis frame 4 is connected to the main shaft 8 of the A-axis torque motor 1 through the expansion sleeve 3 and the connecting flange 2 . For details, please refer to figure 2 , the connecting flange 2 is fixed on the main shaft 8 of the A-axis torque motor 1 by screws, and the connecting flange 2 and the C-axis frame 4 are fixedly connected by an expansion sleeve 3 . According to the same structure and principle, the other side of the C-axis frame 4 is connected to the main shaft of the bearing seat 7 through the expansion sleeve 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com