Processing technology of glass protection

A processing technology and protective film technology, applied in glass production, glass manufacturing equipment, glass cutting devices, etc., can solve problems such as contaminated glass, achieve high yield, reduce production costs, and simple and feasible film removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

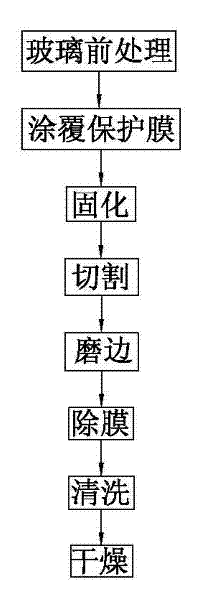

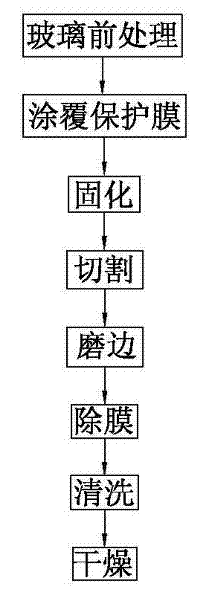

[0018] The processing technology of glass protection of the present invention specifically comprises following operating steps, as figure 1 shown.

[0019] 1. Provide a glass sheet product. If the glass sheet is polluted by dust or other objects during storage, the surface of the glass sheet can be cleaned. Cleaning can be achieved in a variety of ways, including chemical cleaning methods, such as acid washing, lye washing or other cleaning agents, ultraviolet light / ozone cleaning, thermal decomposition, etc. In this embodiment, tap water is used for washing And hot air dry.

[0020] 2. Coat a layer of protective film on the upper and lower surfaces of the glass sheet. Coating protective film can be achieved by various methods, such as: silk screen, roller coating or spraying, etc., to form a protective film with uniform thickness, no bubbl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com