Surface-coated cutting tool

A cutting tool and surface coating technology, which is applied in the field of surface coating cutting tools, can solve the problems of dry machining without lubricant, etc., and achieve improved tool life, excellent wear resistance, excellent fracture resistance and chipping resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

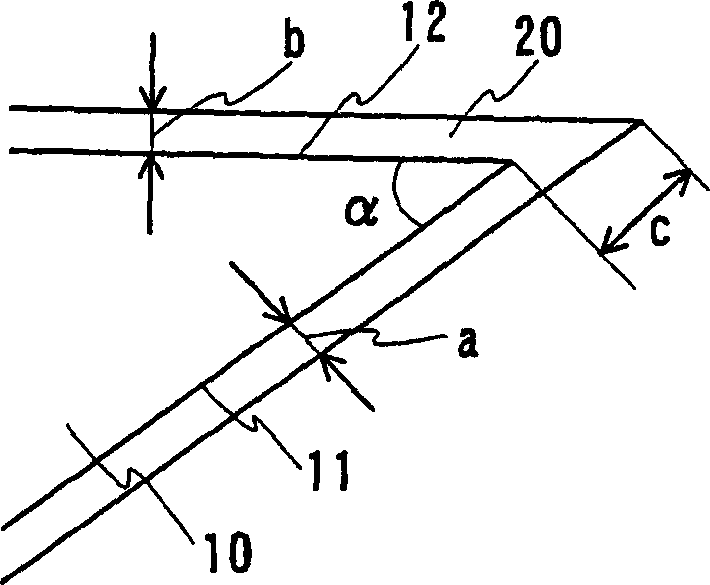

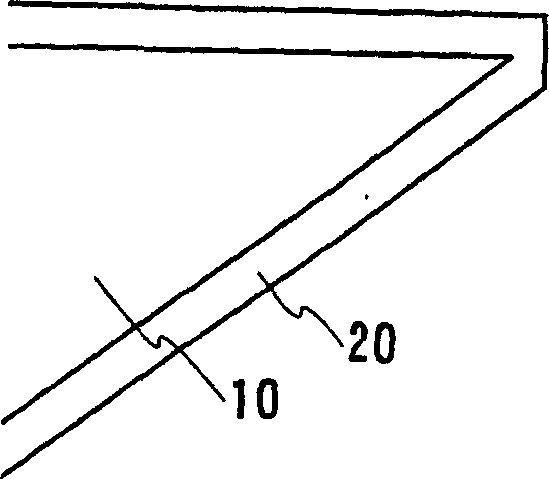

Method used

Image

Examples

Embodiment 1

[0094] The following surface-coated cutting tools for studying wear resistance were prepared.

[0095] (1) Sample preparation

[0096] On a substrate holder of a well-known cathodic arc ion plating equipment, each substrate having an insert shape of SPGN120308 under JIS made of cemented carbide of grade P30 under JIS was placed. As for the substrate holder, a substrate holder that allows water cooling is used. First, reduce the internal pressure of the chamber, and while rotating the substrate holder, heat the insert-shaped substrate to a temperature of 650°C with a heater provided in the device, and evacuate the chamber until the internal pressure reaches 1.0 ×10 -4 Pa. Then, argon gas is introduced into the chamber to maintain the internal pressure of the chamber at 3.0 Pa, and the voltage of the substrate bias power supply is gradually increased to 1500 V for cleaning the surface of the substrate for 15 minutes. Then, the argon gas is discharged from the outside of the chamber....

Embodiment 2

[0109] Separately, by preparing base materials of various drill bits having an outer diameter of 8 mm (Cemented Carbide K10 under JIS) and forming a coating film on the base materials, a drill bit including the coating film was obtained. The same coating films as those of samples 2, 11, 16, 19, 32, 51, and 52 in the aforementioned Example 1 were provided. Use these drill bits containing coating film for drilling SCM440 (H R C30), evaluate tool life.

[0110] The cutting conditions are: the cutting speed is 90m / min, the feed rate is 0.2mm / rev., no coolant is used (using blast), and the blind hole cutting depth is 24mm. When the dimensional accuracy of the workpiece is not within the defined range, the tool life of each sample is determined, and the number of holes formed before the end of the life is evaluated. Table 5 shows the results.

[0111] table 5

[0112]

[0113] As shown in Table 5, it was confirmed that the life spans of samples 2-2, 2-11, 2-16, 2-19, and 2-32 were sig...

Embodiment 3

[0115] Separately, by the same method as in Example 1, a variety of base materials for six-groove end mills with an outer diameter of 8 mm (hard alloy K10 under JIS) were prepared, and a coating film was formed on the base material to obtain a coating containing End mill for membrane. The coating film was prepared in the same manner as those of 2, 11, 16, 19, 32, 51, and 52 in the foregoing Example 1. Use these end mills containing coatings for SKD 11 (H R C60) The end mill is cut sideways to evaluate the life of the tool.

[0116] The cutting conditions are: the cutting speed is 200m / min, the feed ratio is 0.03mm / side, the cutting Ad depth is 12mm, the Rd is 0.2mm, and no coolant is used (air blast). When the dimensional accuracy of the workpiece is not within the limited range, the tool life of each sample is determined, and the cutting length before the end of the life is used for evaluation. Table 6 shows the results.

[0117] Table 6

[0118]

[0119] As shown in Table 6, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com