Secondary optical lens of LED backlight system for flat liquid crystal display

A secondary optical lens and liquid crystal display technology, which is applied in optics, lenses, optical components, etc., can solve problems such as spot black shadows, unreasonable light distribution methods, and light energy loss, and achieve the effect of reducing light energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

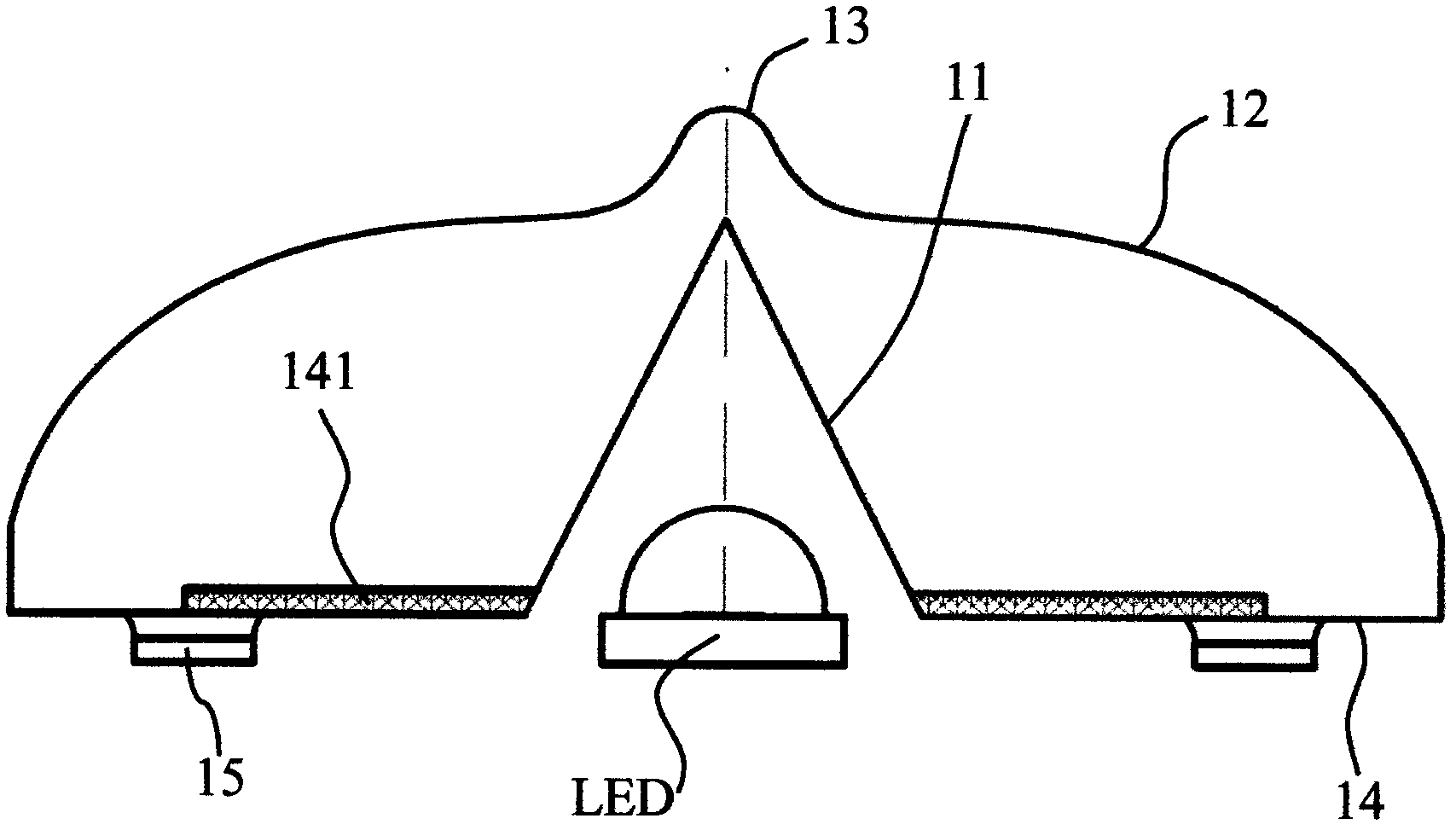

[0052] Such as figure 1 Shown, it is the first specific embodiment of the secondary optical lens of the LED backlight system that the present invention is used for flat liquid crystal display, and the central part of this optical lens bottom has a conical inner concave surface 11, and it is incident surface; Lens There is a flat light distribution curved surface 12 on the top of the lens, which is an exit surface, and it is a continuous smooth curved surface; there is an obvious protrusion 13 at the center of the curved surface 12 on the top of the lens, and the protrusion is arc-shaped; the bottom surface of the lens 14 It is a non-optical surface, on which there is a corner cube prism type retro-reflective microstructure surface 141 for collecting stray light; the so-called corner cube prism refers to an angle cut off from a regular cube, and its three faces are all perpendicular to each other. So it is called a corner cube; a microstructure array formed by arranging the mi...

no. 2 Embodiment approach

[0084] When the phosphor powder of the LED chip is coated relatively thinly and the coating area is relatively large, the secondary optical lens described in the first specific embodiment is used to distribute the light emitted by the LED. Since the light distribution angle is very large, it is possible On the screen, there will be inconsistencies such as high color temperature in the center of the light spot and low color temperature at the edge of the light spot, resulting in poor color uniformity of the LCD panel. The second specific embodiment described in the present invention proposes a solution to this situation.

[0085] The sectional view of the second specific embodiment is as Figure 14As shown, except for the outer light distribution curved surface 22, all other features are the same as the first specific embodiment. Here, the outer light distribution curved surface 22 is designed as a diffractive surface with ring microstructures, so that the outgoing light surrou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com