Structure for packing light-emitting diodes, light-conducting pipe and liquid crystal display device thereof

A technology of liquid crystal display devices and light-emitting diodes, which is applied in the field of liquid crystal display devices and backlight modules, and can solve problems such as not being environmentally friendly, reducing the practicability of backlight module liquid crystal display devices, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

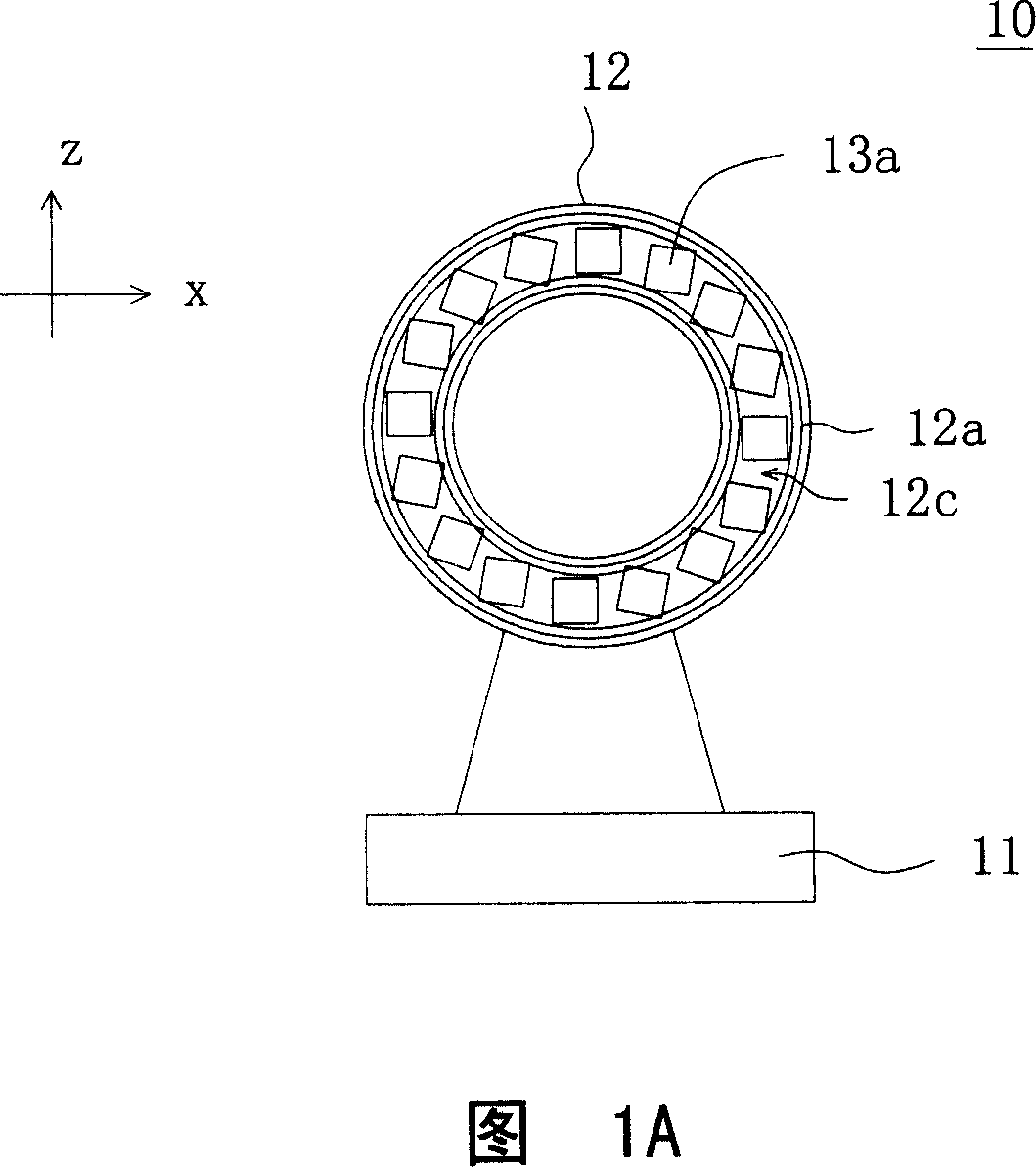

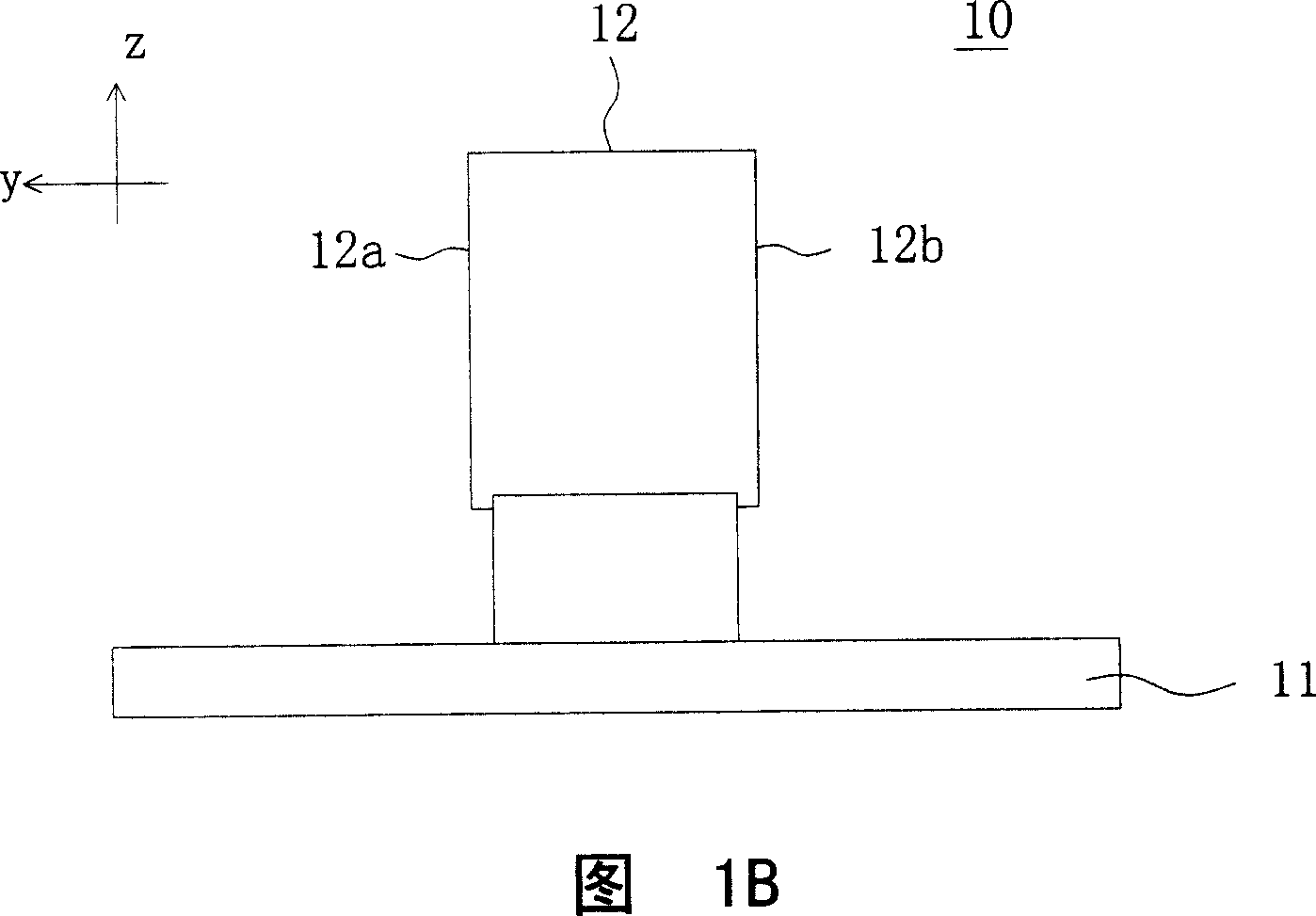

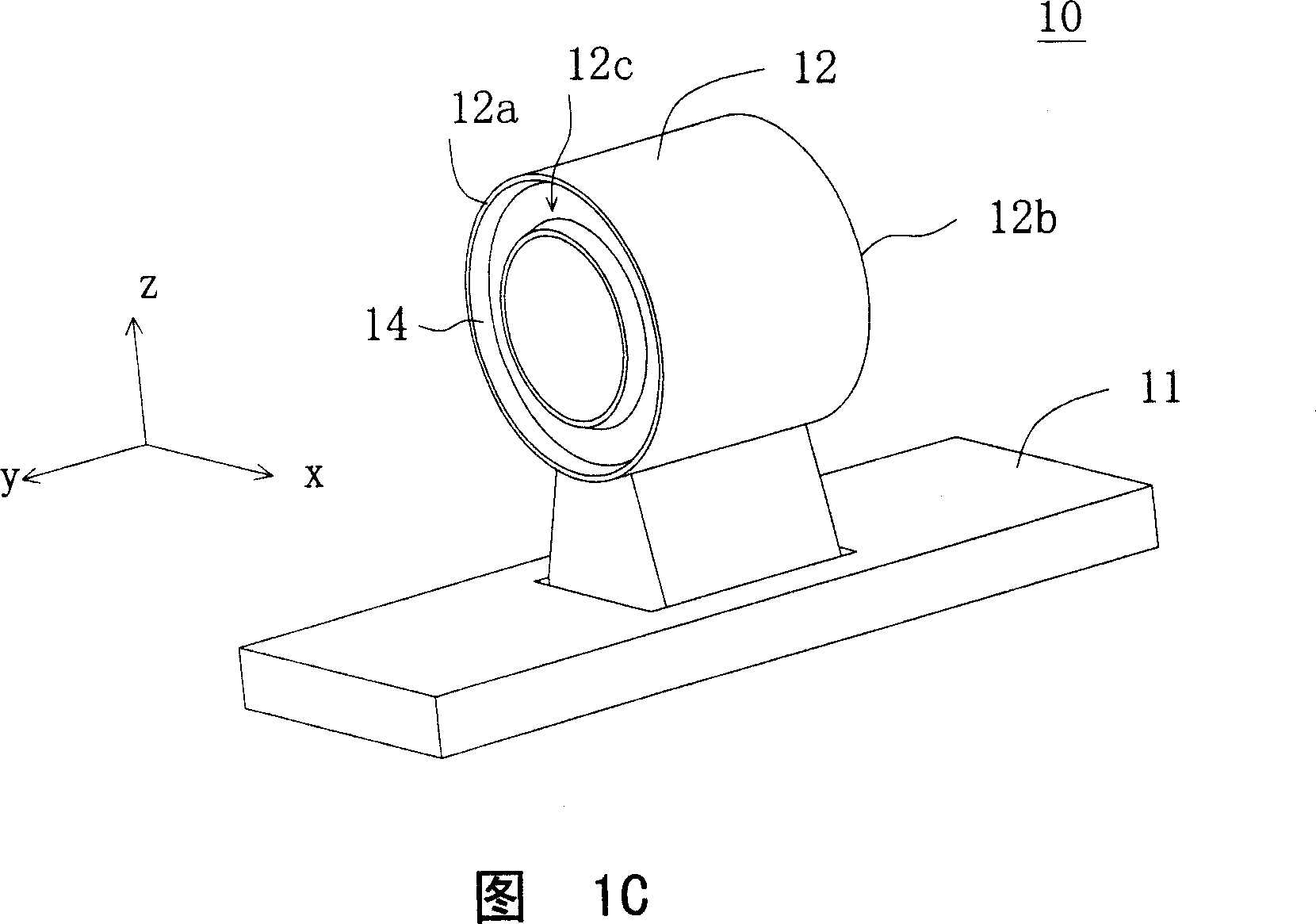

[0074] Please refer to FIGS. 1A-1E at the same time. FIG. 1A shows a front view of the LED packaging structure according to Embodiment 1 of the present invention, and FIG. 1B shows a side view of the LED packaging structure of FIG. 1A . Fig. 1C shows a perspective view of the base and body of the light emitting diode package structure of Fig. 1A, Fig. 1D shows a front view of the state when the light emitting diode structure of Fig. 1A also includes phosphor powder and colloid, and Fig. The diode structure also includes the back view of the state of the phosphor and colloid.

[0075] As shown in FIGS. 1A-1B , the LED packaging structure 10 includes a base 11 , a body 12 and a plurality of first LED chips 13 a. The body 12 is disposed on the base 11, and has a first side 12a, and the first side 12a has a groove 12c surrounding an edge. The first LED chip 13 a is disposed on the bottom of the first edge-surrounding groove 12 c for providing single side light of the LED package ...

Embodiment 2

[0081] Please refer to FIGS. 2A-2C at the same time. FIG. 2A shows a perspective view of a light guide according to Embodiment 2 of the present invention. Fig. 2B shows a sectional view of the light pipe viewed from the +x direction with the yz plane of Fig. 2A as the sectional plane, and Fig. 2C shows a sectional view with the xz plane of Fig. 2A as the sectional plane and from the +y direction An enlarged cross-sectional view of the light pipe looking into the light pipe. As shown in FIGS. 2A-2C , the light guide pipe 20a is used to receive light from a light source at least at one end thereof and perform light interference. The light pipe 20a includes a cylinder 21 and several prism structures 22a. The cylinder 21 has an outer peripheral side 21a and an inner reflective surface 21b, and the inner reflective surface 21b is used for reflecting the light received by the light pipe 20a. The prism structure 22a is disposed between the outer peripheral side 21a and the inner re...

Embodiment 3

[0088] Please refer to FIG. 3 , which shows a cross-sectional view of a light guide according to Embodiment 3 of the present invention. The difference between the light guide pipe 20b of the present embodiment and the light guide pipe 20a of the second embodiment lies in the prism structure 22b, as for the other same constituent elements, the reference numerals continue to be used and will not be repeated here.

[0089]As shown in FIG. 3, although the prism structure 22b of the present embodiment and the prism structure 22a of the second embodiment are both dots, the dots of the present embodiment are pits, that is, the prism structure 22b is a pit. As for the formation method of the light guide pipe 20b, it is substantially the same as the formation method of the light guide pipe 20a in the second embodiment, and will not be repeated here. In addition, the distribution and formation of the prism structures 22b are substantially the same as the distribution and formation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com