Patents

Literature

112 results about "Mixed spectrum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

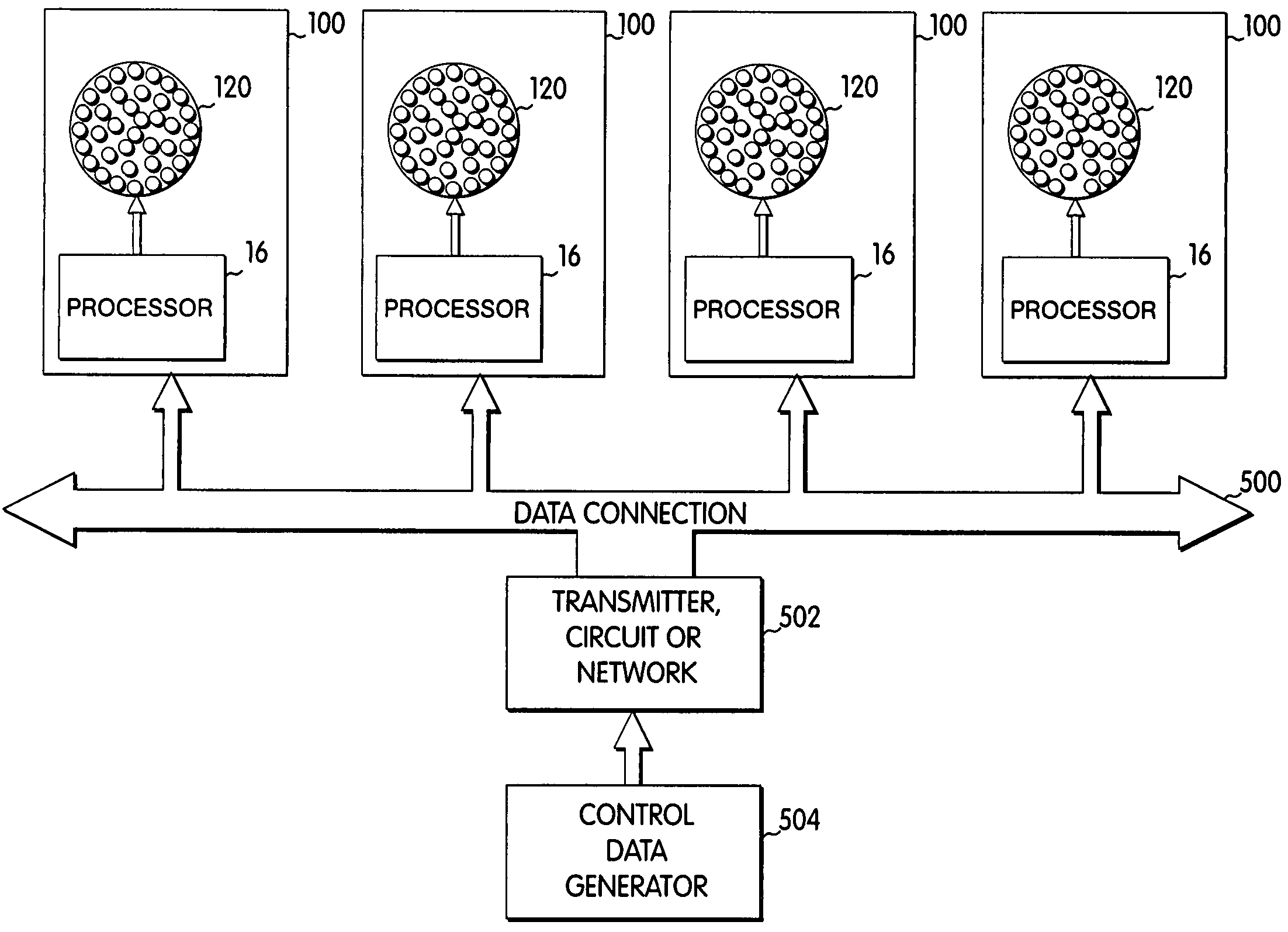

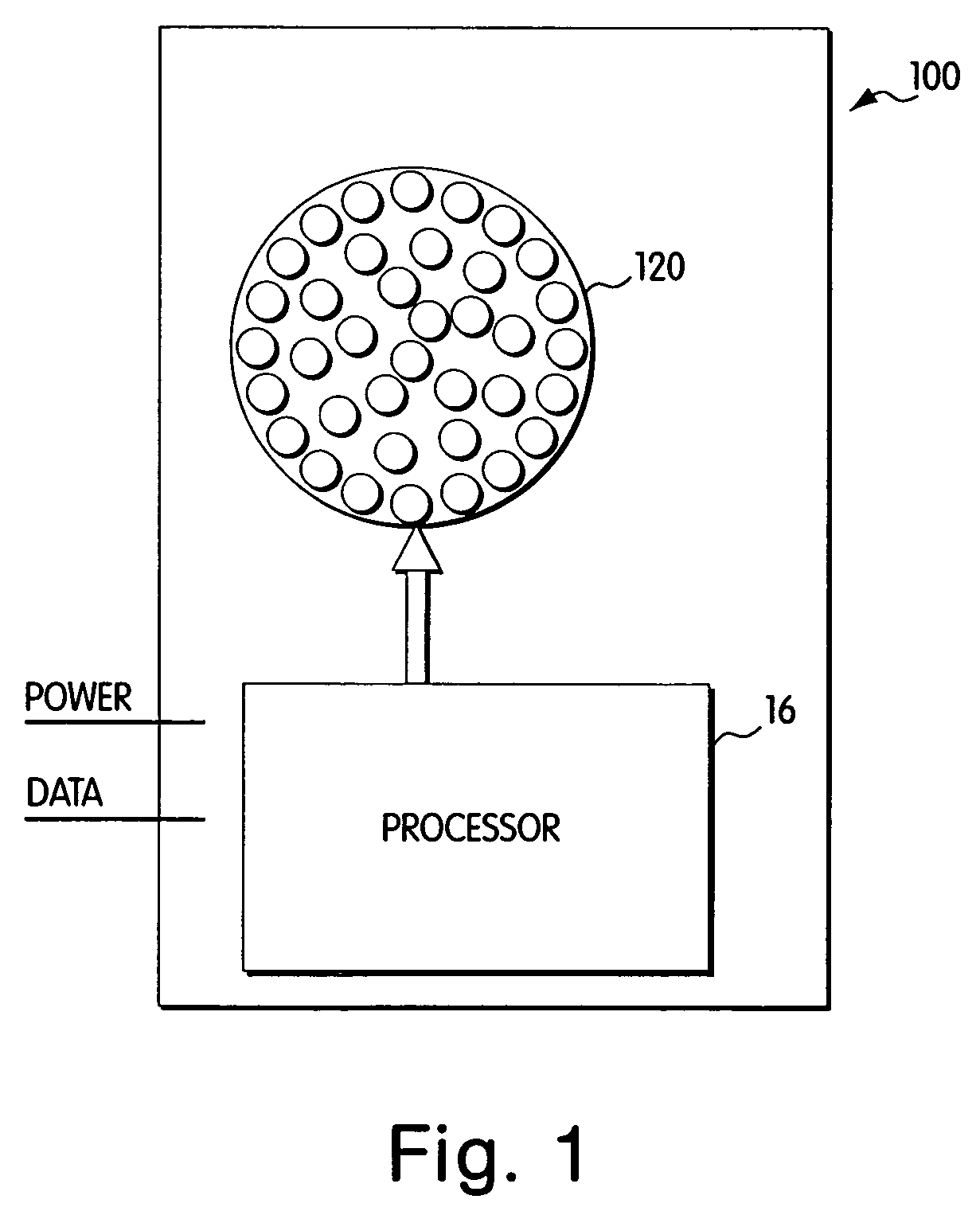

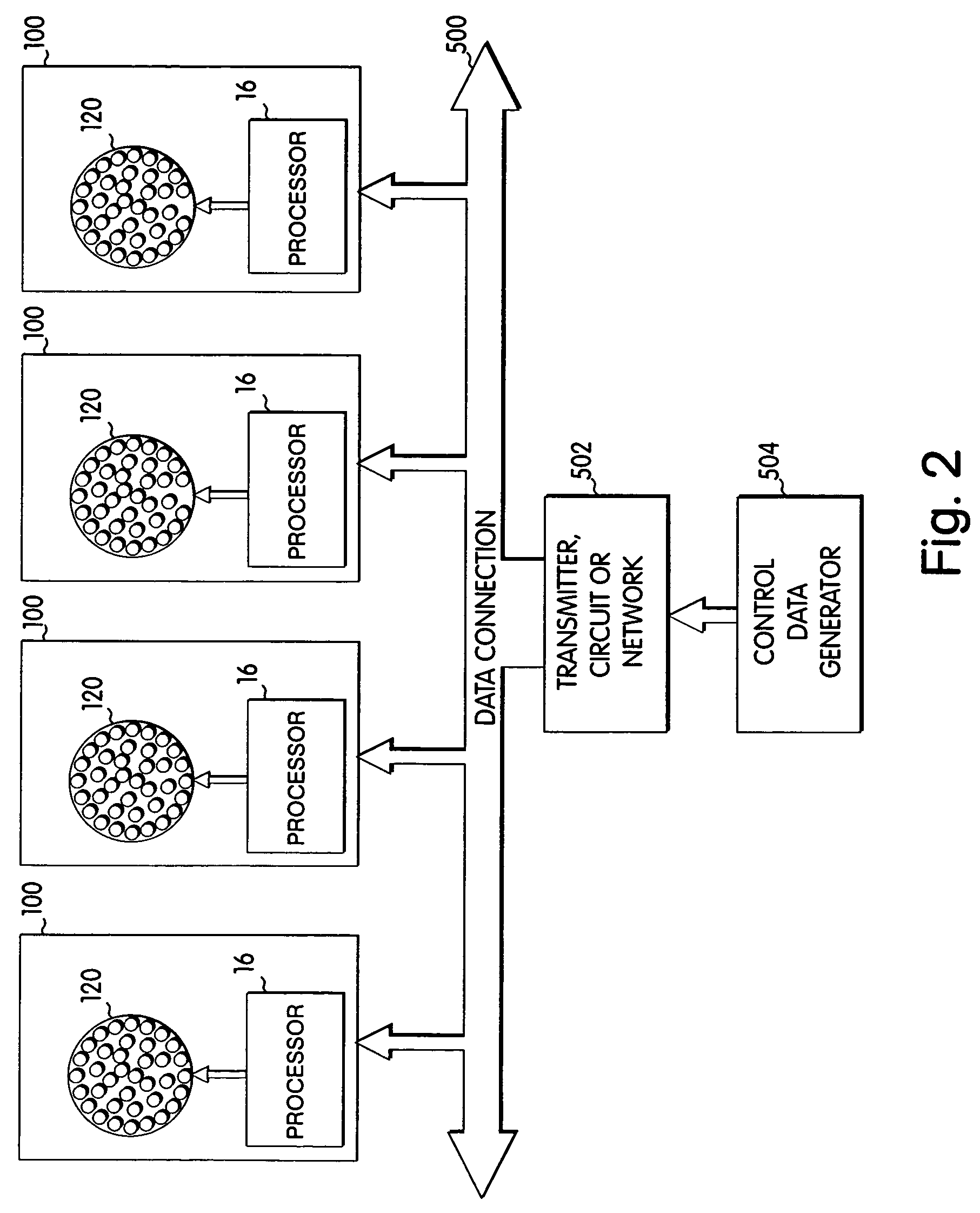

Geometric panel lighting apparatus and methods

Methods and apparatus for generating at least one variable color lighting effect over at least a two-dimensional observation area. In various examples, at least first radiation having a first spectrum and second radiation having a second spectrum different than the first spectrum are generated from a plurality of LEDs. One or more geometric panels are disposed with respect to the LEDs so as to at least partially diffuse the first radiation and the second radiation to provide a mixed spectrum when both the first radiation and the second radiation are generated. A first intensity of the first radiation and a second intensity of the second radiation are independently controlled at a plurality of graduated intensities from a minimum intensity to a maximum intensity so as to generate a variety of dynamic lighting effects over one or more two-dimensional observations areas covered by the one or more geometric panels.

Owner:PHILIPS LIGHTING NORTH AMERICA CORPORATION

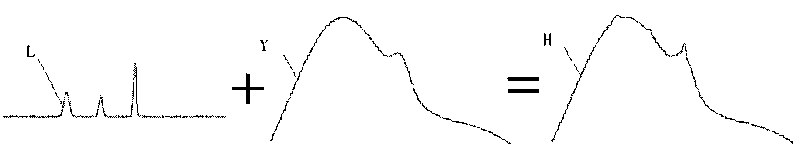

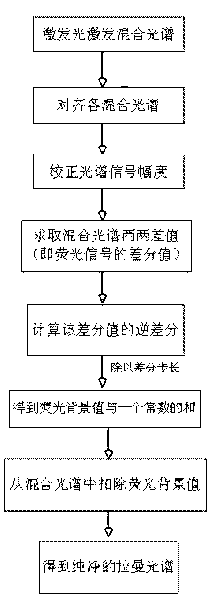

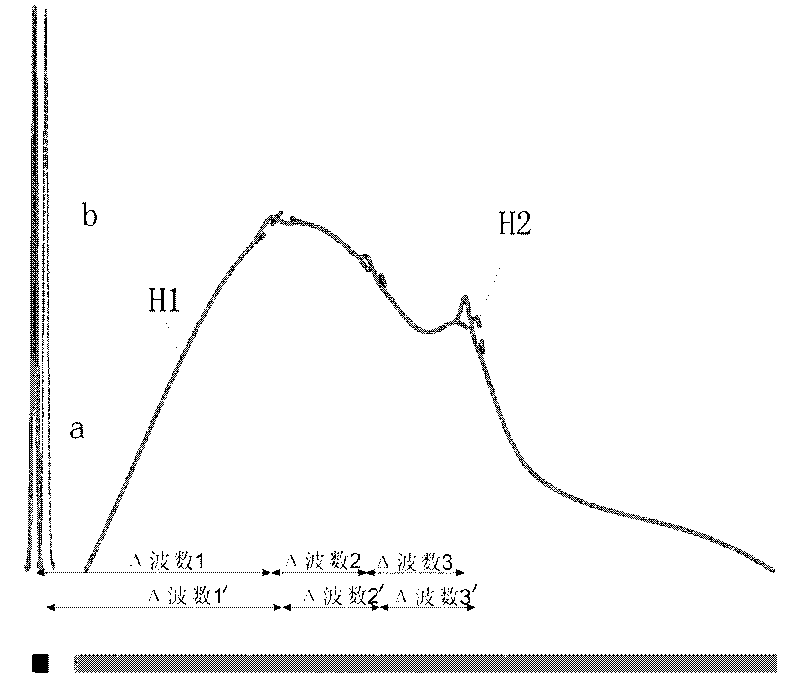

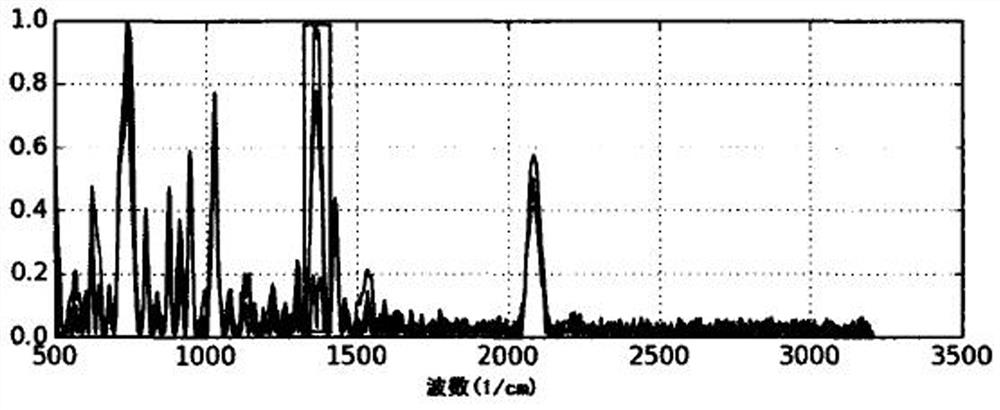

Multi-wavelength excitation-based fluorescence elimination method for Raman spectrum

InactiveCN101692045AReasonable methodEliminate background fluorescenceRaman scatteringMixed spectrumOpto electronic

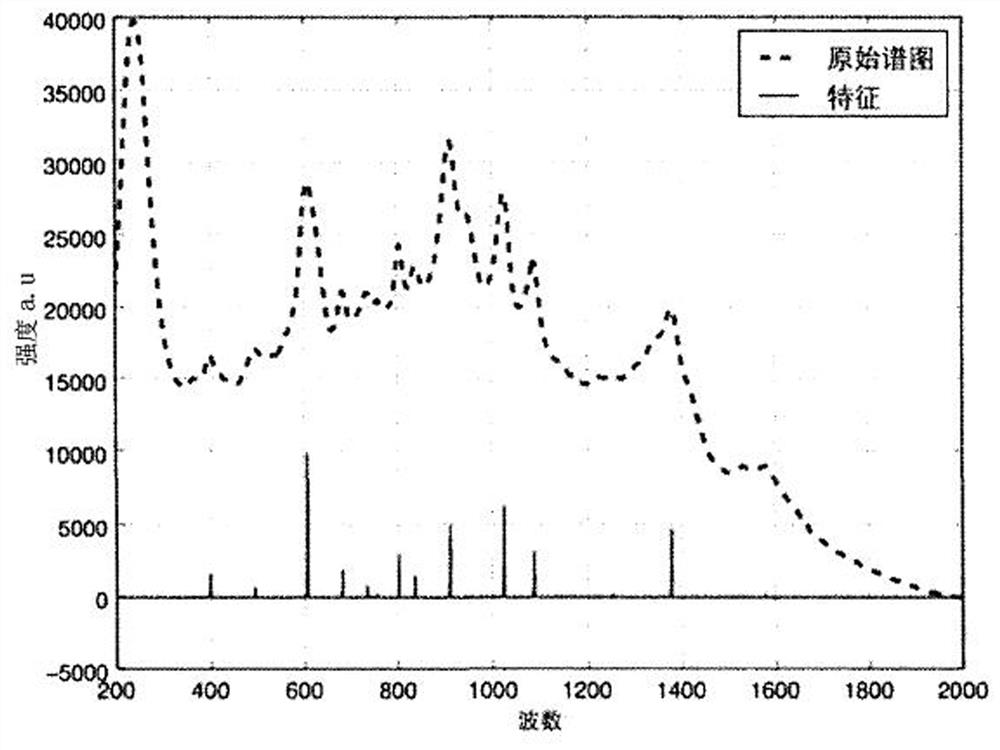

The invention discloses a multi-wavelength excitation-based fluorescence elimination method for Raman spectrum, which relates to a method of chemical analysis and photoelectric signal processing and comprises the steps of: sequentially exciting mixed spectra consisting of fluorescence and Raman light by irradiating a plurality of similar wavelength lasers sequentially generated by a laser source to the same measured sample; when a spectrograph acquires various mixed spectrum signals, aligning the mixed spectra, and normalizing and correcting the amplitude of the spectrum signals through a full spectrum integral value to obtain spectra of which the X-coordinates are aligned and the amplitude of the Y-coordinates is corrected; evaluating a difference value between each two mixed spectra, wherein the difference value is a differential value of a fluorescence signal; calculating an inverse difference of the differential value, wherein the inverse difference is divided by a differential step to obtain the sum of a fluorescence background value and a constant; and finally, deducting the fluorescence background value from the mixed spectra to separate a pure Raman spectrum so as to achieve the aim of fluorescence elimination of the Raman spectrum. The method is reasonable, can eliminate background fluorescence effectively, has low cost and convenient use, and is easy to popularize and use.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

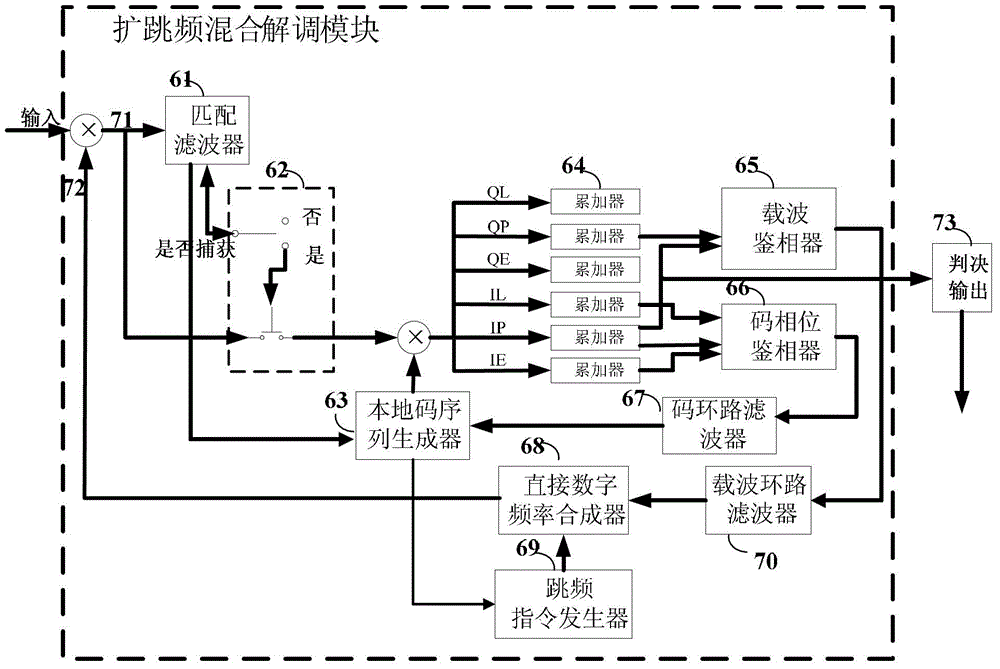

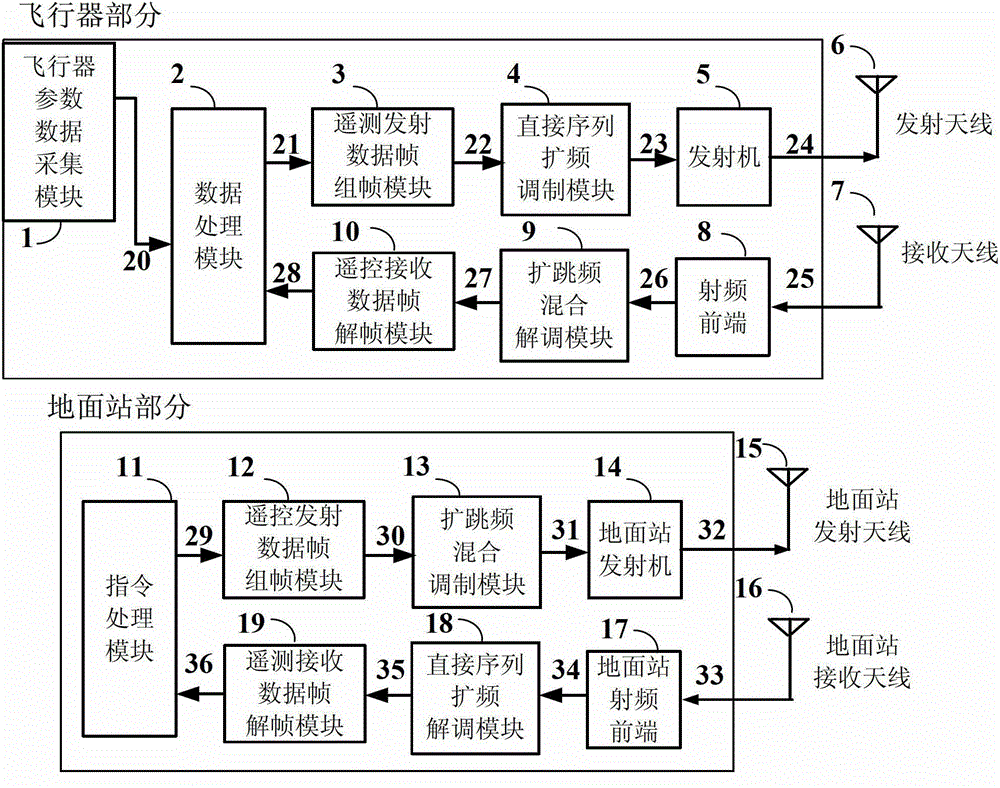

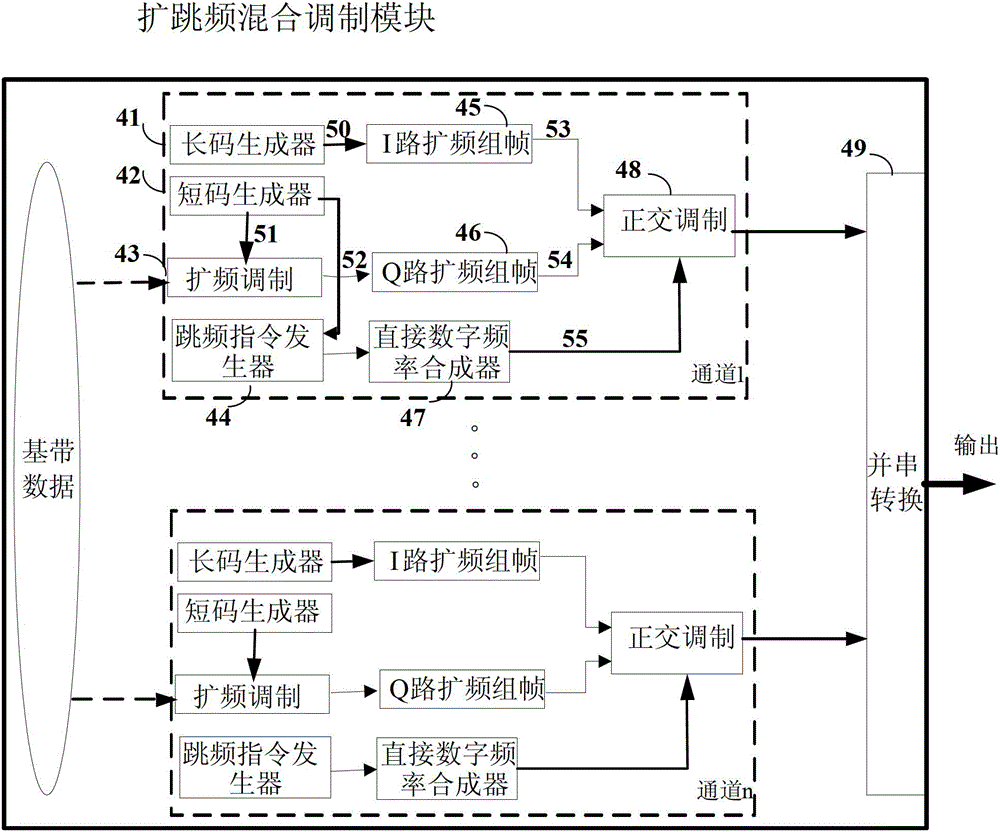

Air vehicle measurement and control system with upper and down links utilizing different spectrum spreading systems

The invention discloses an air vehicle measurement and control system with upper and down links utilizing different spectrum spreading systems. An upper remote control link of the system is based on a direct spreading_frequency hopping mixed spectrum spreading system, and a down remote measuring link of the system utilizes a direct sequence spectrum spreading system. The air vehicle measurement and control system is divided into an air vehicle part and a ground station part, wherein an air vehicle parameter data collection module, a data processing module, a remote measuring data frame transmission and framing module, a direct sequence spectrum spreading modulation module, a transmitter, a transmission antenna, a receiving antenna, a radio frequency front end module, a spreading frequency hopping mixed demodulation module and a remote control data frame receiving and decoding module are carried on the air vehicle; and the ground station part comprises an instruction processing module, a remote control data frame transmission and framing module, a spreading frequency hopping mixed modulation module, a ground station transmitter, a ground station transmission antenna, a ground station receiving antenna, a ground station radio frequency front end module, a direct sequence spectrum spreading demodulation module and a remote measuring data frame receiving and decoding module. The air vehicle measurement and control system has the advantages of being strong in anti-interference performance and anti-intercept performance and suitable for being used under complex electromagnetic environments.

Owner:BEIHANG UNIV

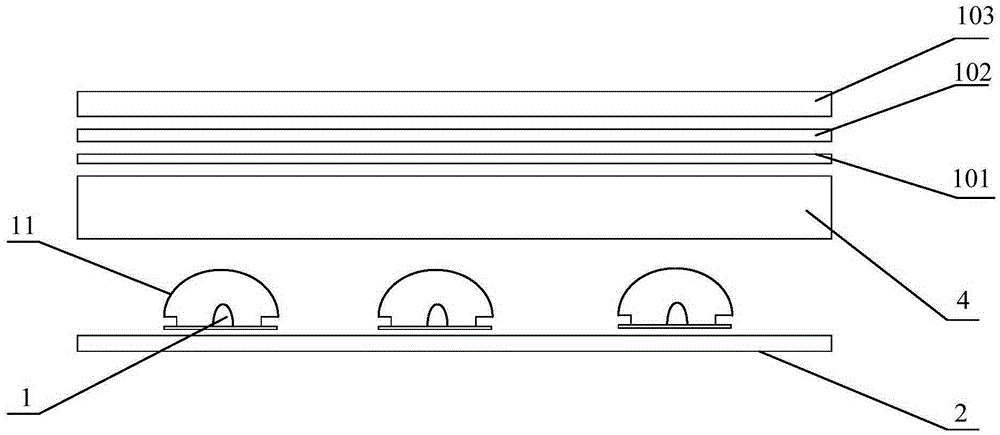

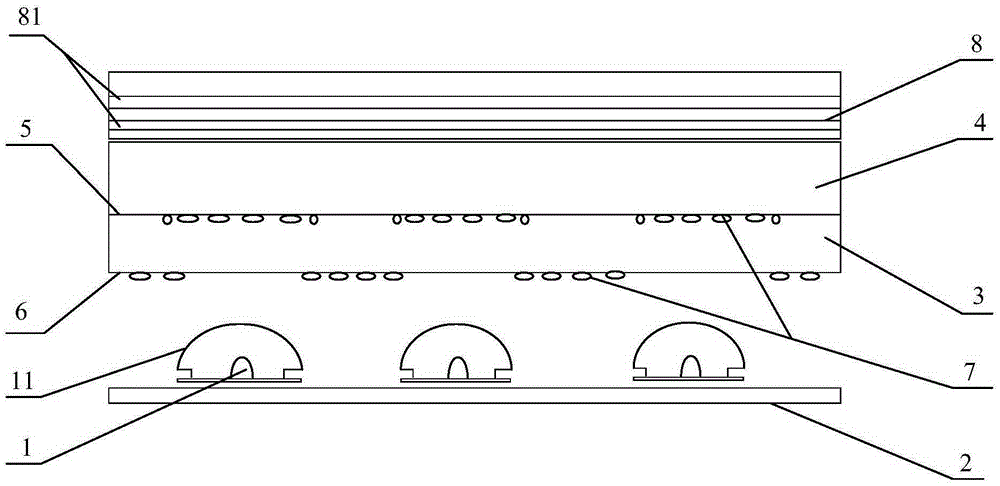

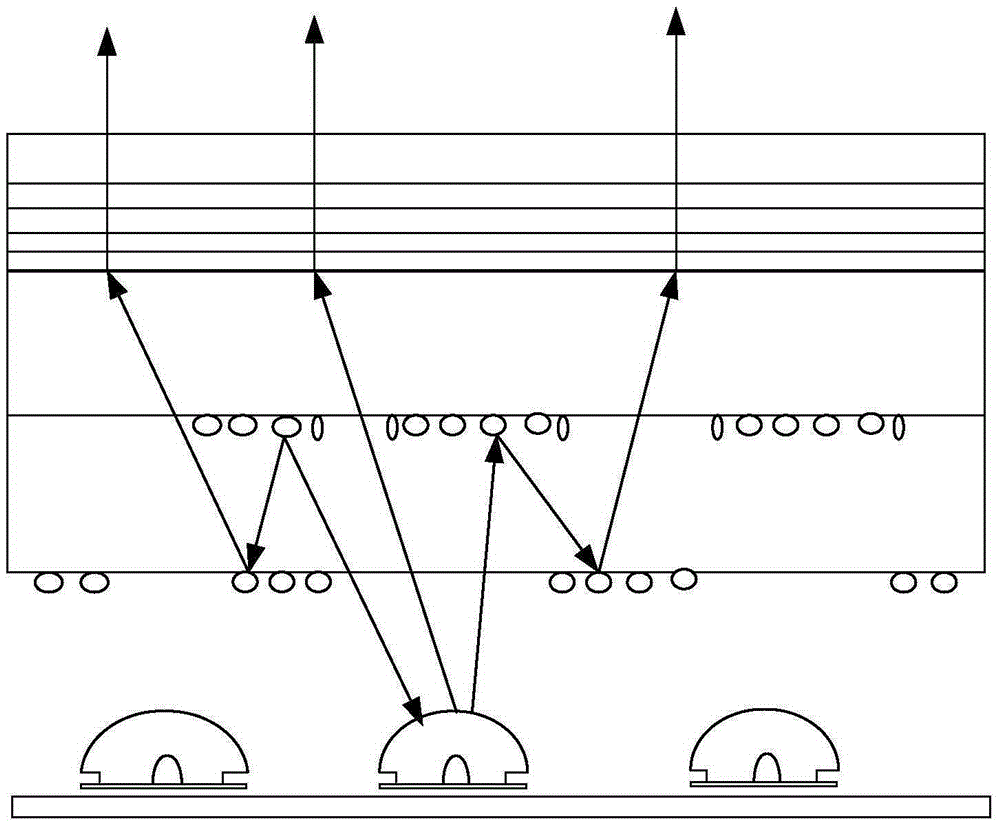

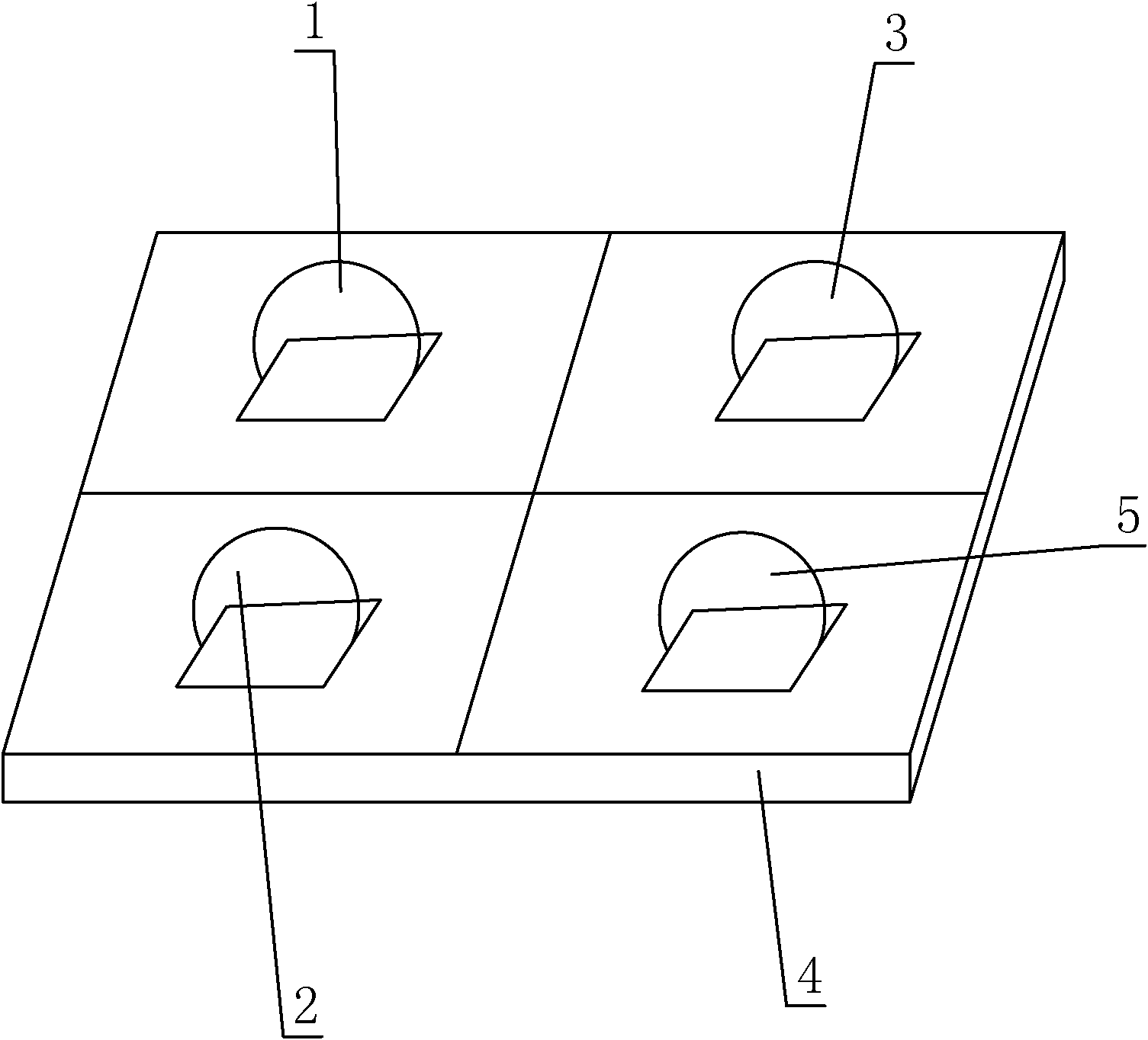

Backlight module set and display device

The invention provides a backlight module set and a display device. The backlight module set comprises an LED lamp, a reflection plate, a light guide layer and a diffusion plate, wherein the reflection plate is arranged on one side of the LED lamp; the other side of the LED lamp is orderly provided with the light guide layer and the diffusion plate; the light guide layer is arranged between the light guide layer and the diffusion plate; and lattice points capable of reflecting light rays are arranged on a connection surface between the diffusion plate and the light guide layer, and the bottom surface of the light guide layer and facing the LED lamp. Mixed spectrum distance of the direct backlight module set can be reduced and a super-thinning display device can be achieved.

Owner:HISENSE VISUAL TECH CO LTD

System and method for configuring LED backlight module with high color saturation

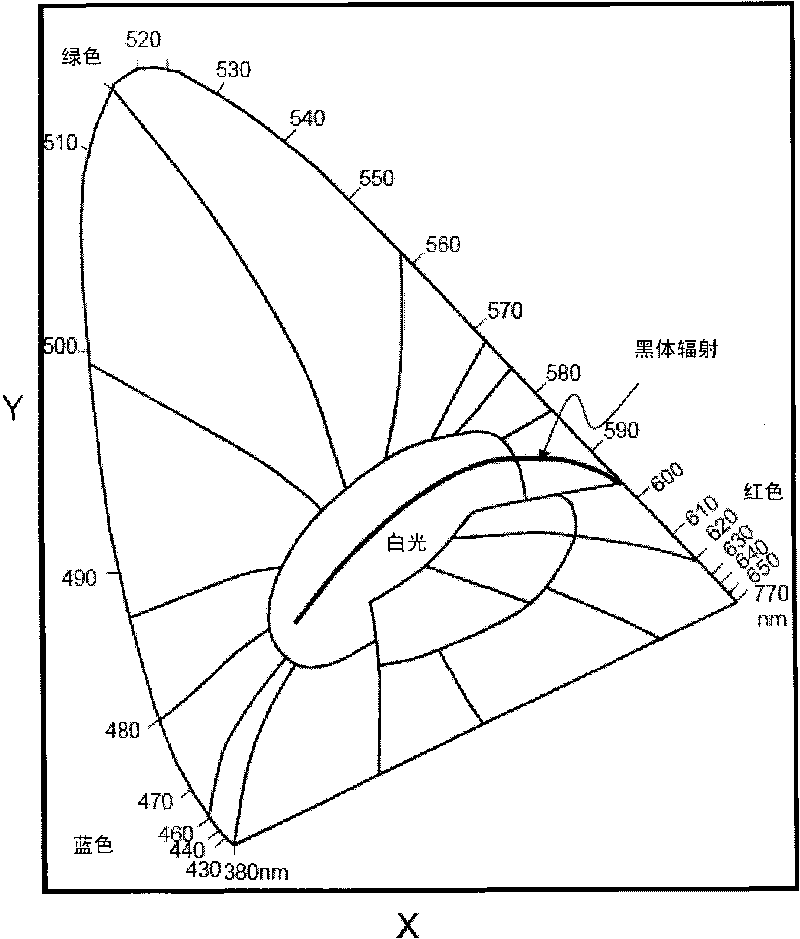

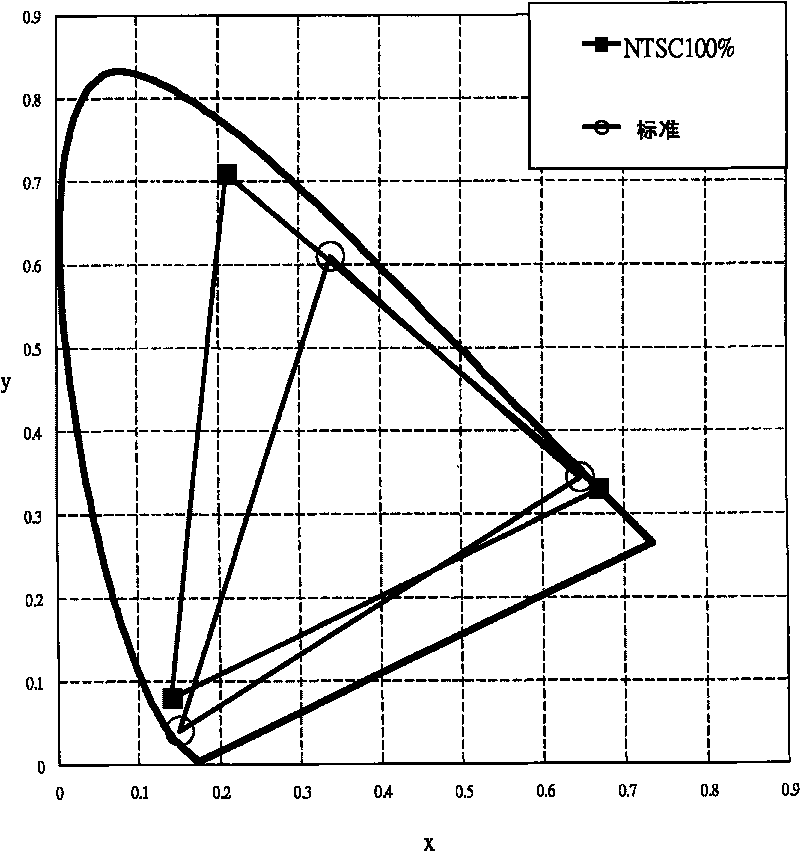

InactiveCN101725843ARapid deploymentHigh color saturationPoint-like light sourceElectric lightingFrequency spectrumBlack-body radiation

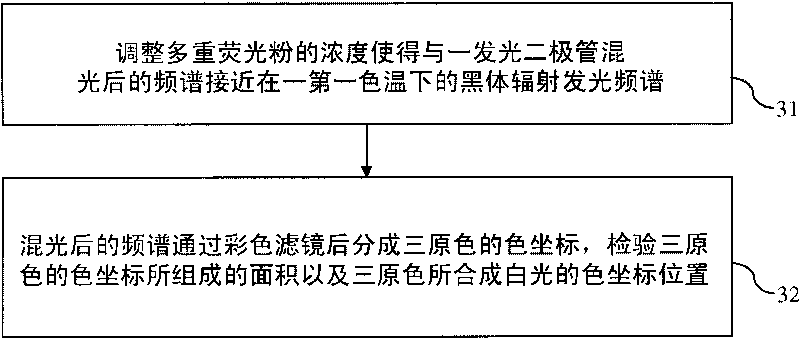

The invention provides a system and a method for configuring an LED backlight module with high color saturation. The method comprises the following steps of: calculating a standard spectrum, wherein the standard spectrum is the spectrum of visible light transmitted by black-body radiation under a first color temperature; providing a transmission spectrum of an LED, a transmission spectrum of first fluorescent powder and a transmission spectrum of second fluorescent powder; according to the standard spectrum, adjusting the concentrations of the first fluorescent powder and the second fluorescent powder to obtain the first light mixed spectrum, and making the first light mixed spectrum closer to the standard spectrum; and making the first light mixed spectrum undergo color separation by a color filter to form a color coordinate of three primary colors, calculating an area formed by the color coordinate of three primary colors, and calculating a position of the color coordinate of the white light formed by the three primary colors. The method mainly uses the algorithms to calculate the concentrations of multiple fluorescent powder, so that after the light of the multiple fluorescent powder is mixed with the light of the LED, the backlight module with high color saturation is provided.

Owner:ZHANJING TECH SHENZHEN +1

Method for identifying components of a mixture via spectral analysis

ActiveUS7409299B2Easy to detectEasy to identifySpectral/fourier analysisMolecular entity identificationFeature vectorSorting algorithm

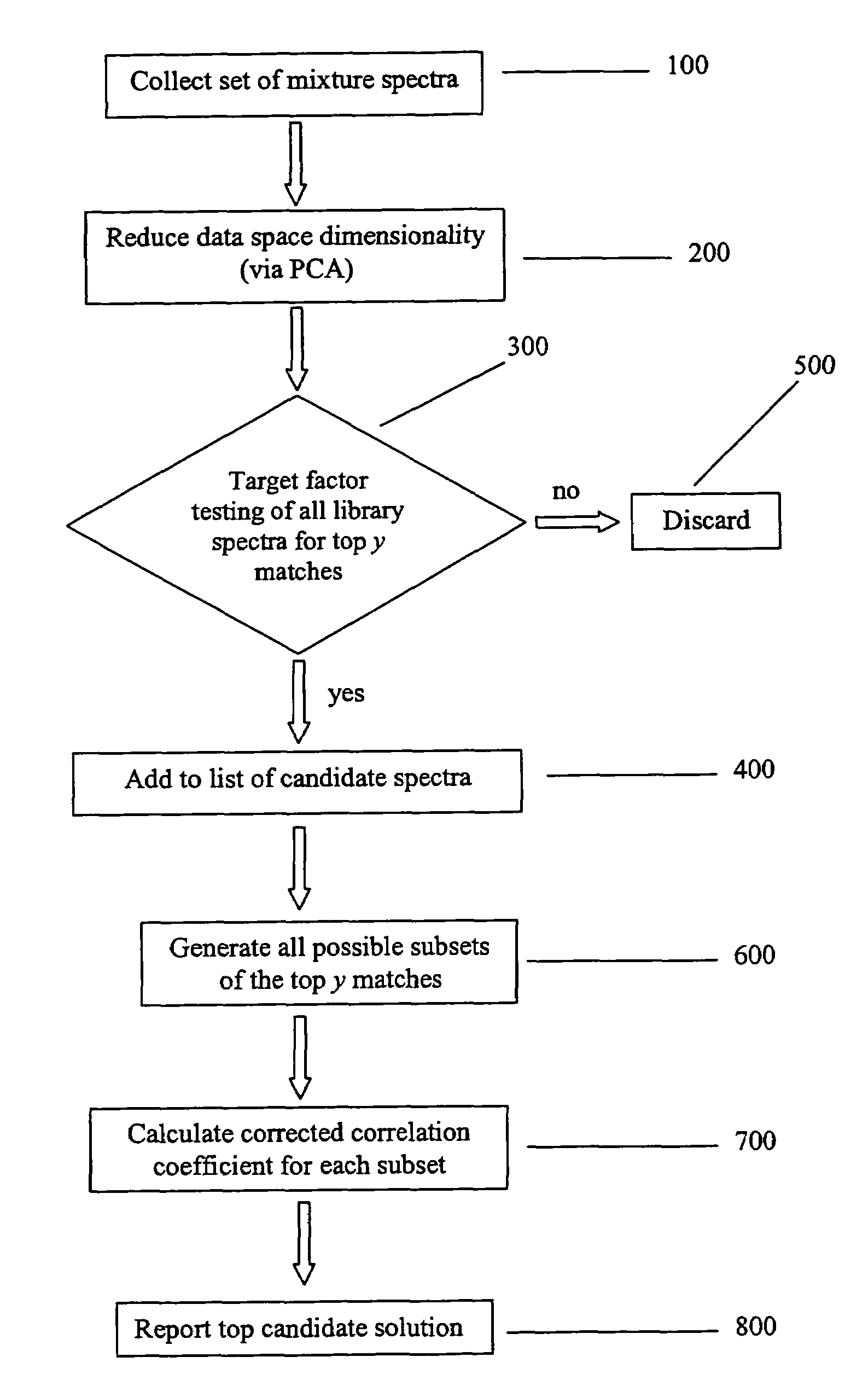

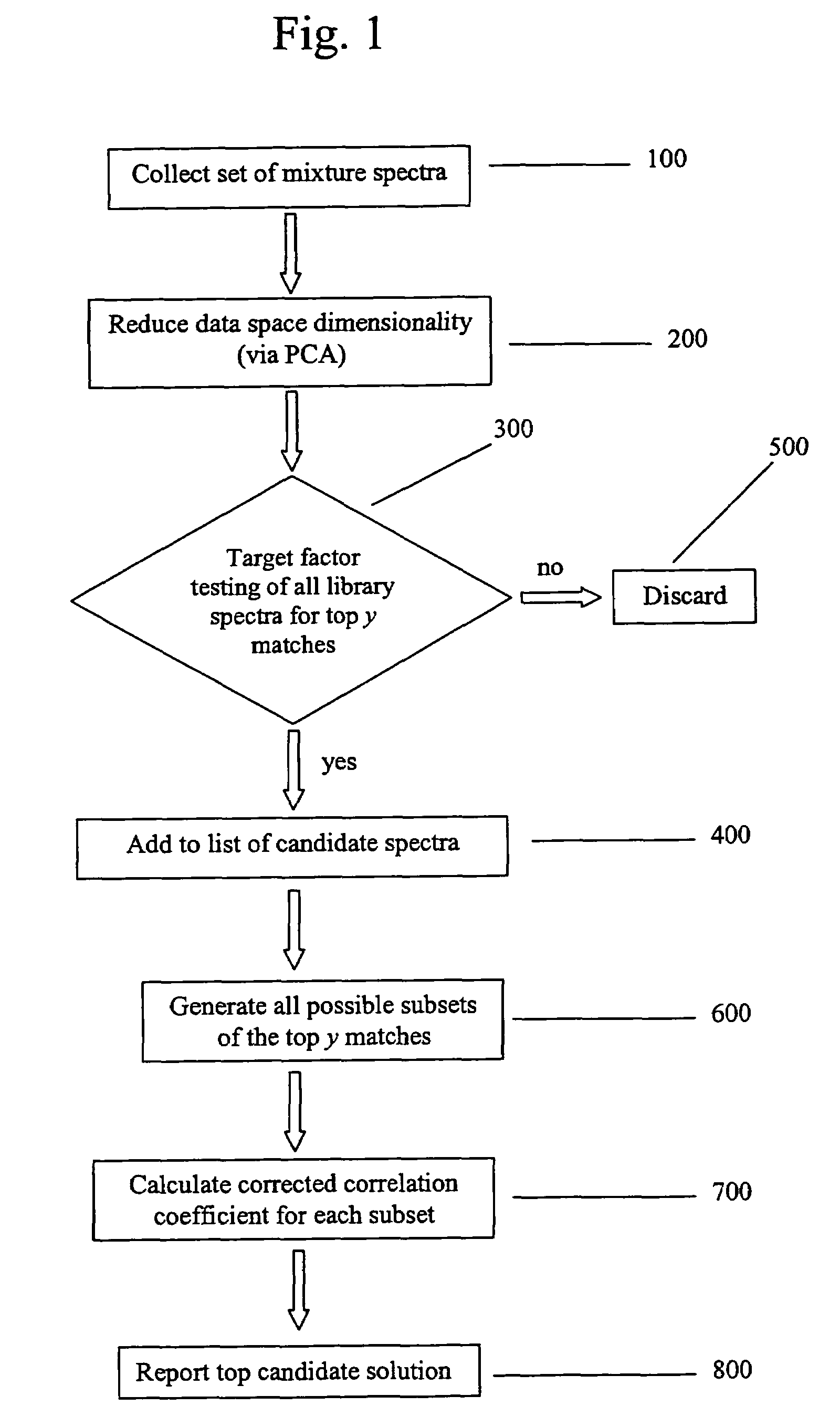

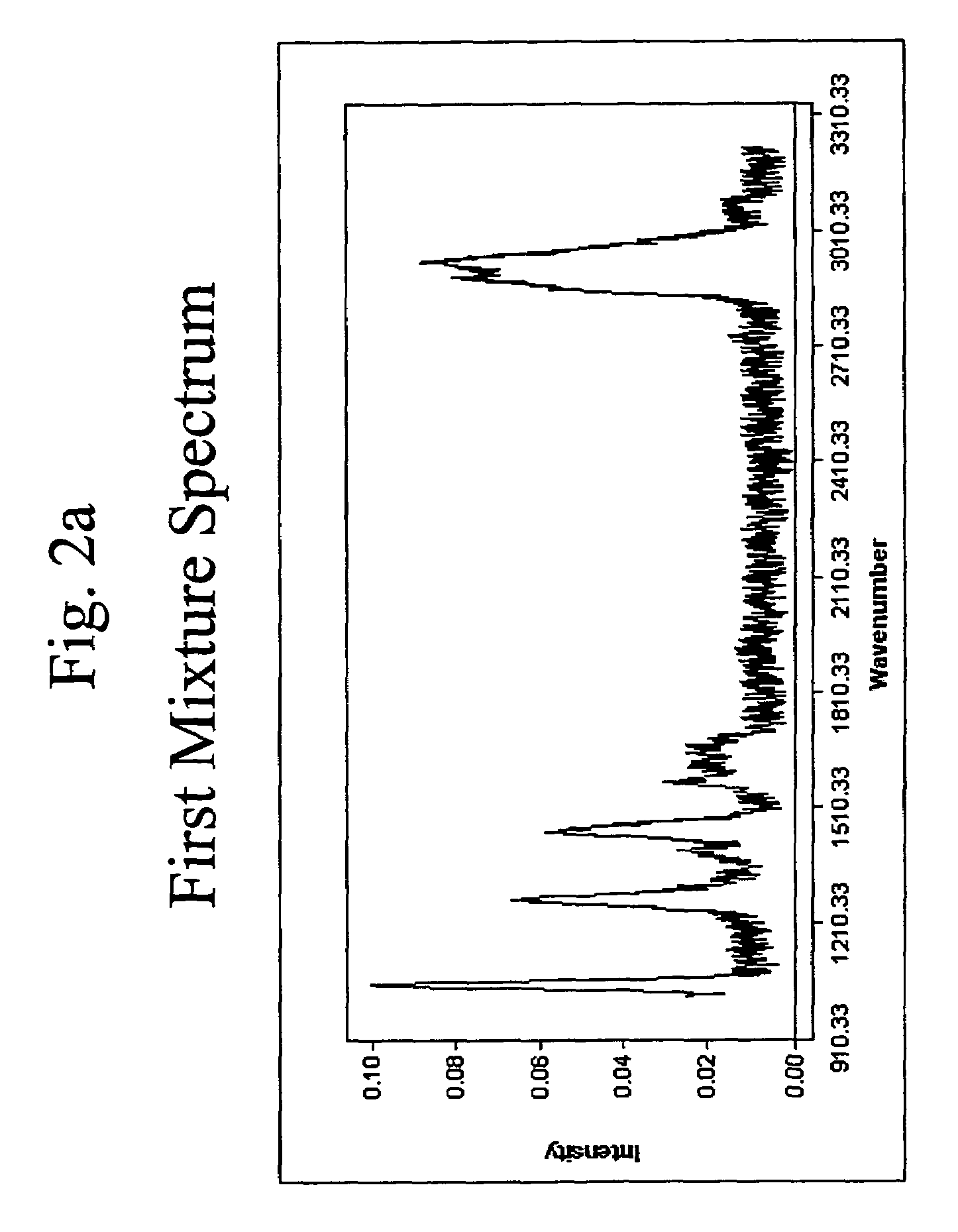

Spectra data collected from a mixture defines an n-dimensional data space (n is the number of data points), and application of PCA techniques yields a subset of m-eigenvectors that effectively describe all variance in that data space. Bach member of a library of known components is examined based by representing each library spectrum as a vector in the m-dimensional space. Target factor testing techniques yield an angle between this vector and the data space. Those library members that have the smallest angles are considered to be potential mixture members and are ranked accordingly. Every combination of the top y library members is considered as a potential solution and a multivariate least-squares solution is calculated using the mixture spectra for each of the potential solutions. A ranking algorithm is then applied and used to select the combination that is most likely the set of pure components in the mixture.

Owner:CHEMIMAGE TECH LLC

Self-adaption finite element light source reconstruction method based on simple spectrum or mix segment measurement

InactiveCN101292863AReduce morbidityBalanceDiagnostic recording/measuringSensorsNumerical stabilityMixed spectrum

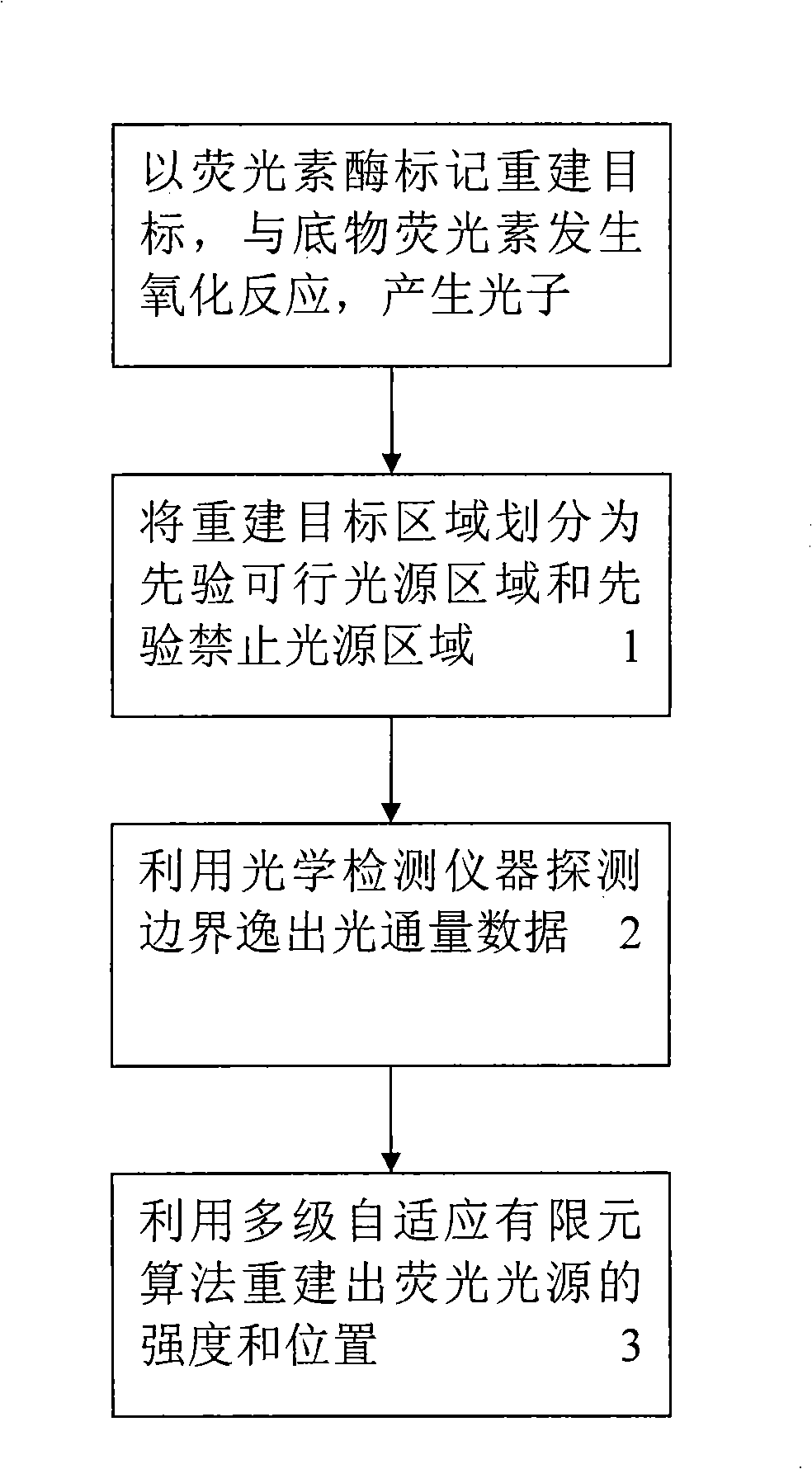

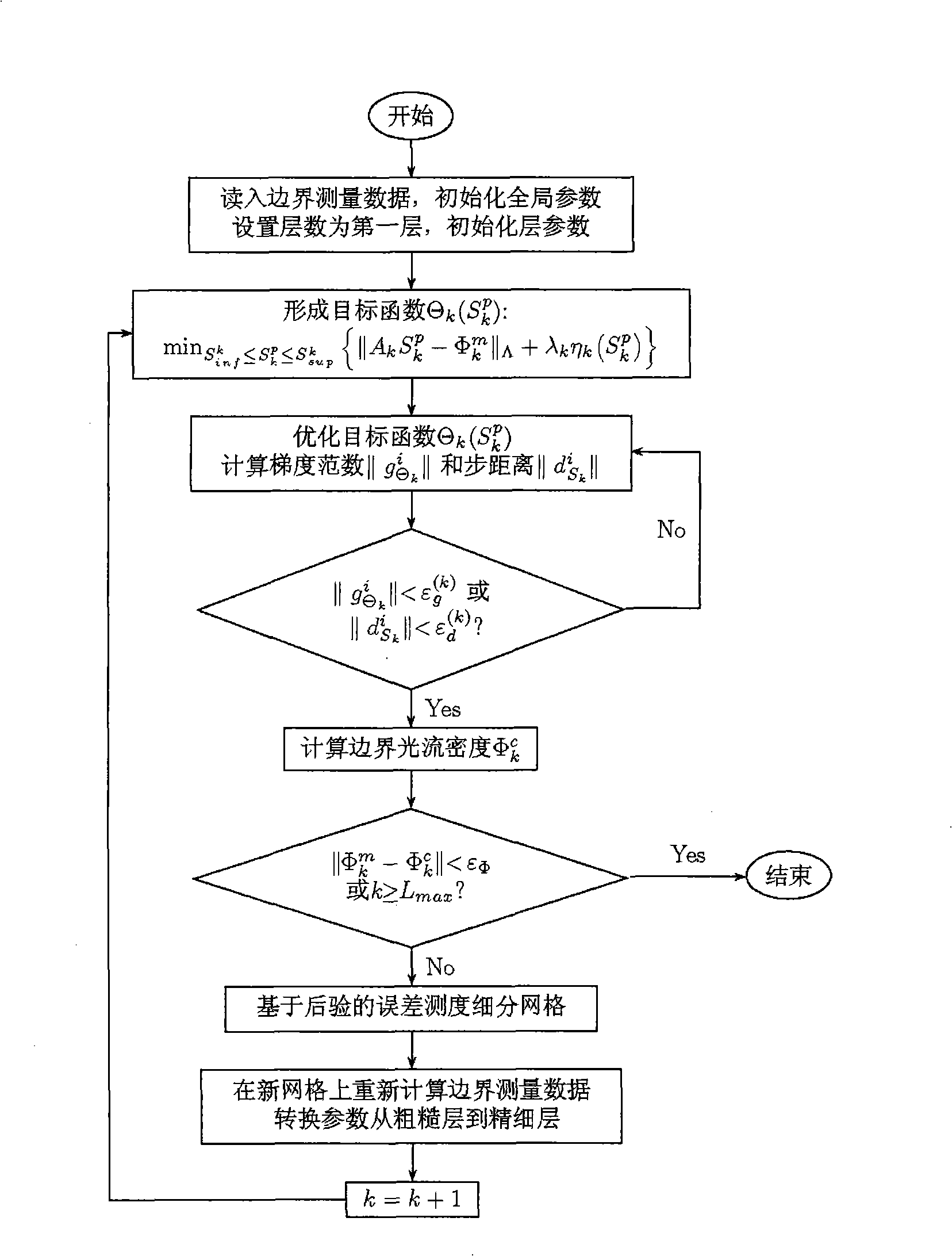

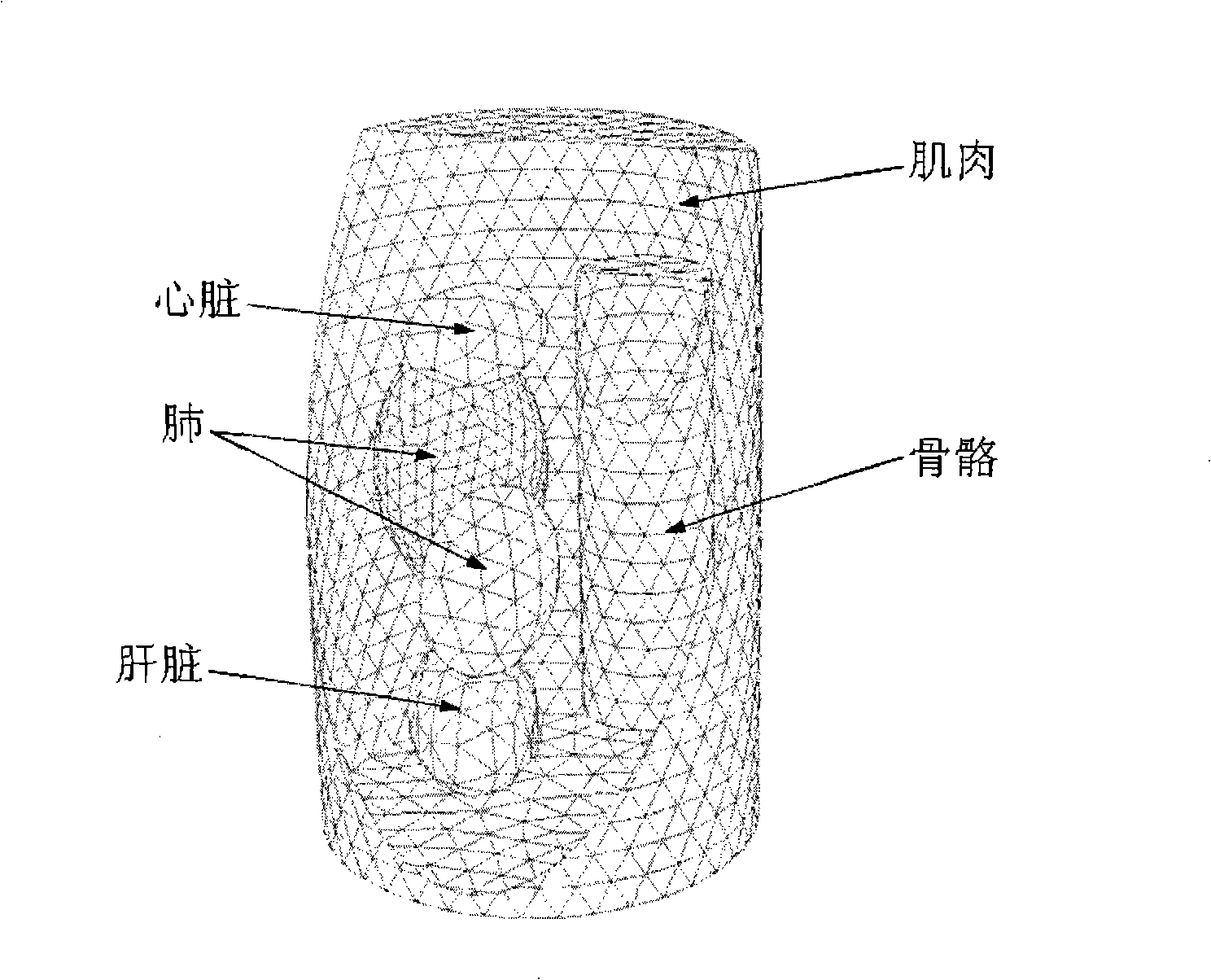

The present invention discloses a self-adaptive finite element optical source rebuilding method based on single spectrum or mixed spectrum measurement. A prior feasible optical source area and a prior forbidden optical source area are confirmed by the optical characteristic parameter and the dissection structure information of a target rebuilding area. Partial gridding is optimized and decomposed by single spectrum or mixed spectrum light flux measurement data at the boundary of the target rebuilding area to be combined with multilevel self-adaptive finite element and a posteriori error estimation method, so as to obtain a fluorescent optical source inside the target rebuilding area. Therefore, based on the single spectrum or mixed spectrum boundary measurement data, the method of the present invention adopts the prior feasible optical source area to reduce the morbidity characteristic of bioluminescence tomography and ensures that the present invention can confirm the only solution; the self-adaptive finite element method is used for balancing gridding partitioning degree, algorithm efficiency and value stability and the partial gridding is optimized according to the posteriori error estimation, which improves quality, efficiency and robustness of the fluorescent optical source rebuilding.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Gaussian multi-peak fitting-based spectrum analysis algorithm

ActiveCN107462535AHigh affinityKeep valid informationColor/spectral properties measurementsComplex mathematical operationsSpectral curveMixed spectrum

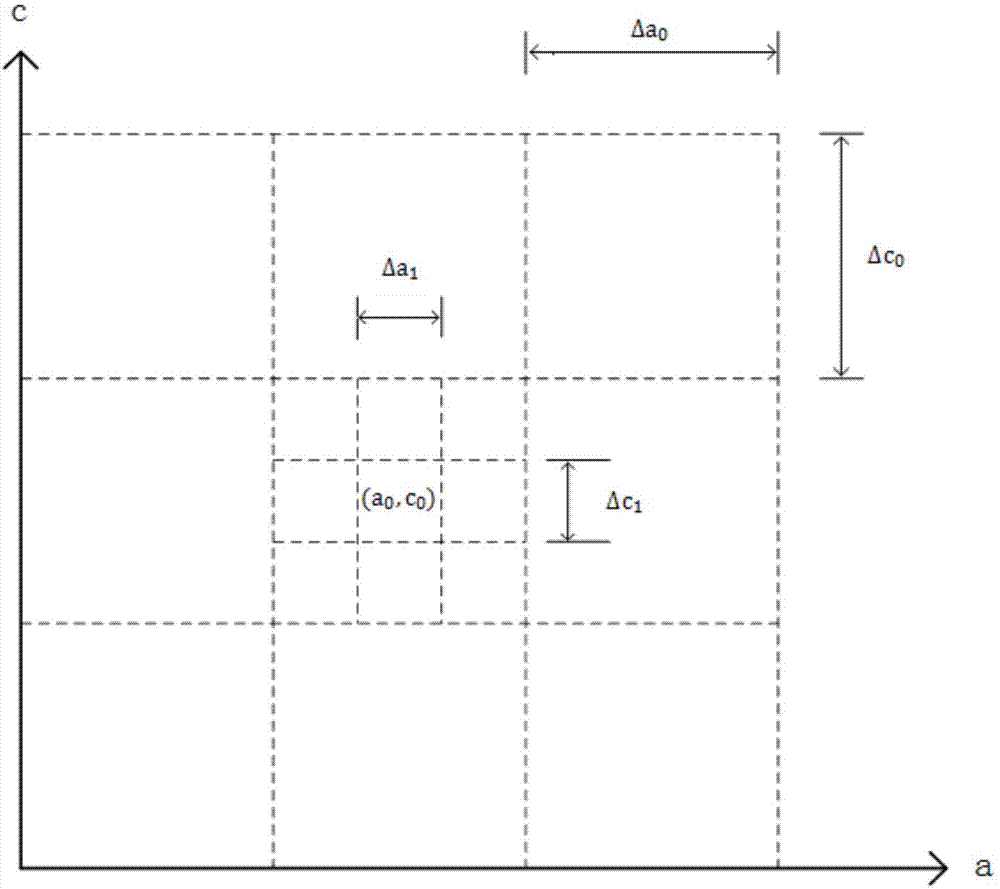

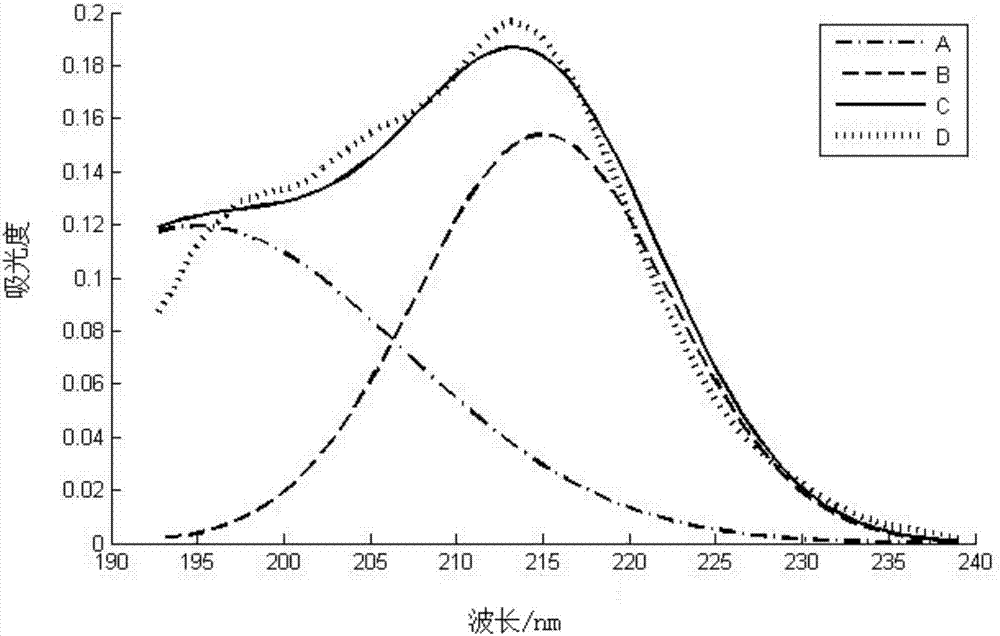

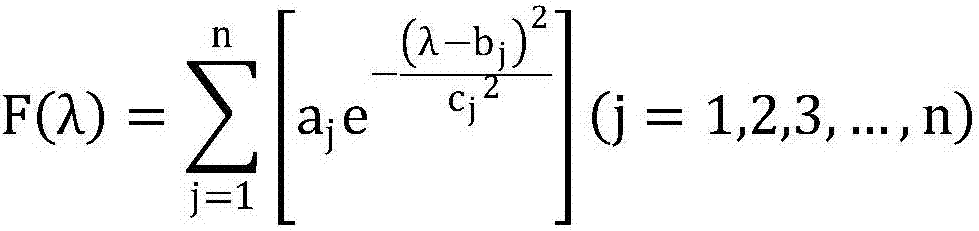

The invention discloses a Gaussian multi-peak fitting-based spectrum analysis algorithm. The Gaussian multi-peak fitting-based spectrum analysis algorithm comprises the following steps: determining an absorption fitting function containing an undetermined Gaussian feature parameter, performing mathematical modeling on fitting error, determining center coordinate and iteration step of an iteration initial value, continuously performing iteration, performing comparison and changing the iteration step length until the optimal fitting error is obtained, and reversely deducing the center coordinate value, namely the to-be-determined feature parameter, of the corresponding division unit by the optimal fitting error, and determining the absorption fitting function so as to decompose the mixed spectrum into a plurality of sub-peaks. The Gaussian multi-peak fitting-based spectrum analysis algorithm has the following advantages: a Gaussian function curve and a spectroscopic data curve have high affinity and can express parameters, such as peak shape, peak height and peak position in the spectrogram, with clear physical significance; and the mixed absorption spectrum curve is decomposed into a plurality of Gaussian function curves, the effective information of the original spectrum data can be remained, the original spectrum data is unified into a small amount of uniquely determined Gaussian feature parameters, and the aims of simplifying the spectrum data and researching the refined structure are fulfilled.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

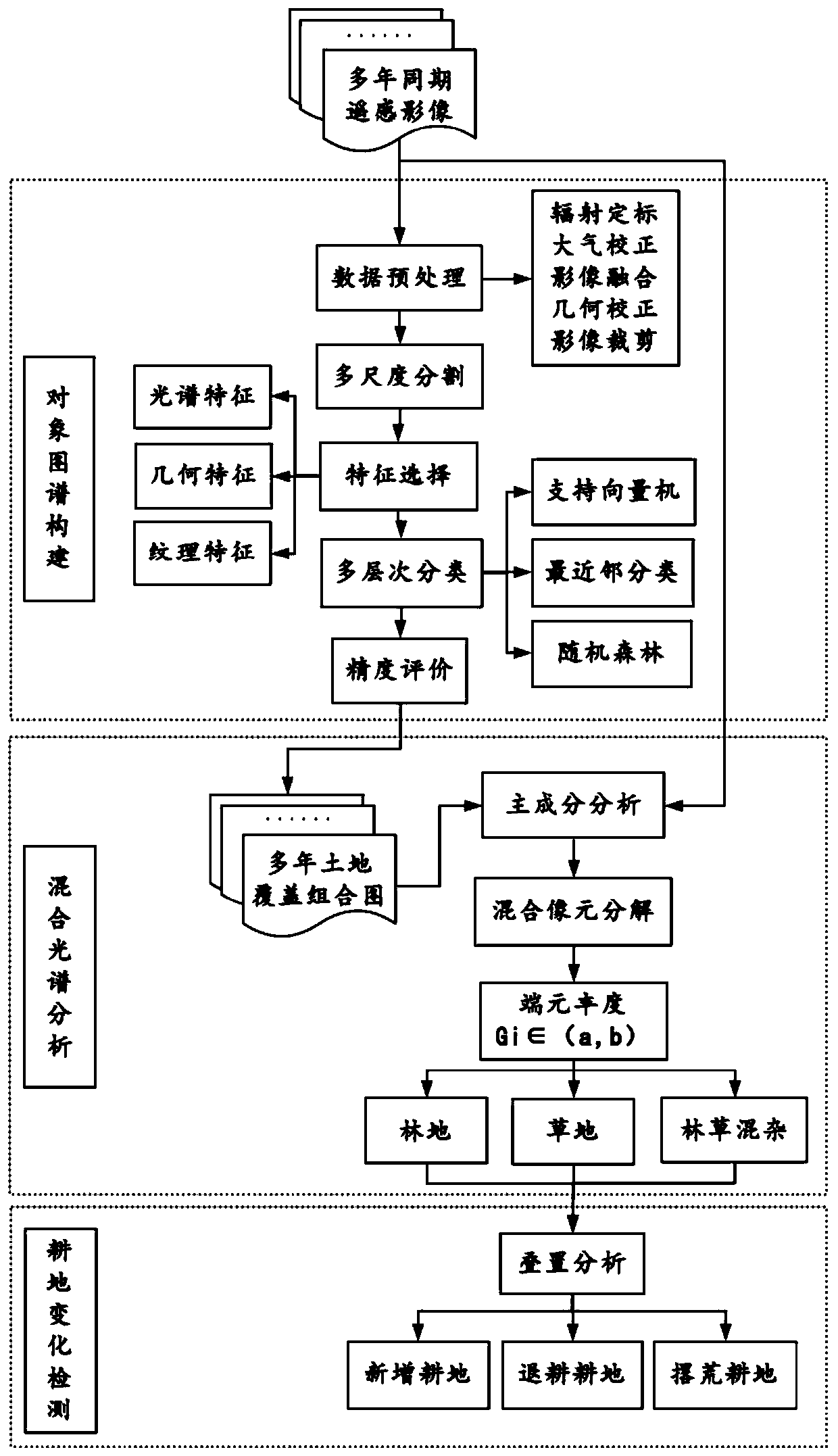

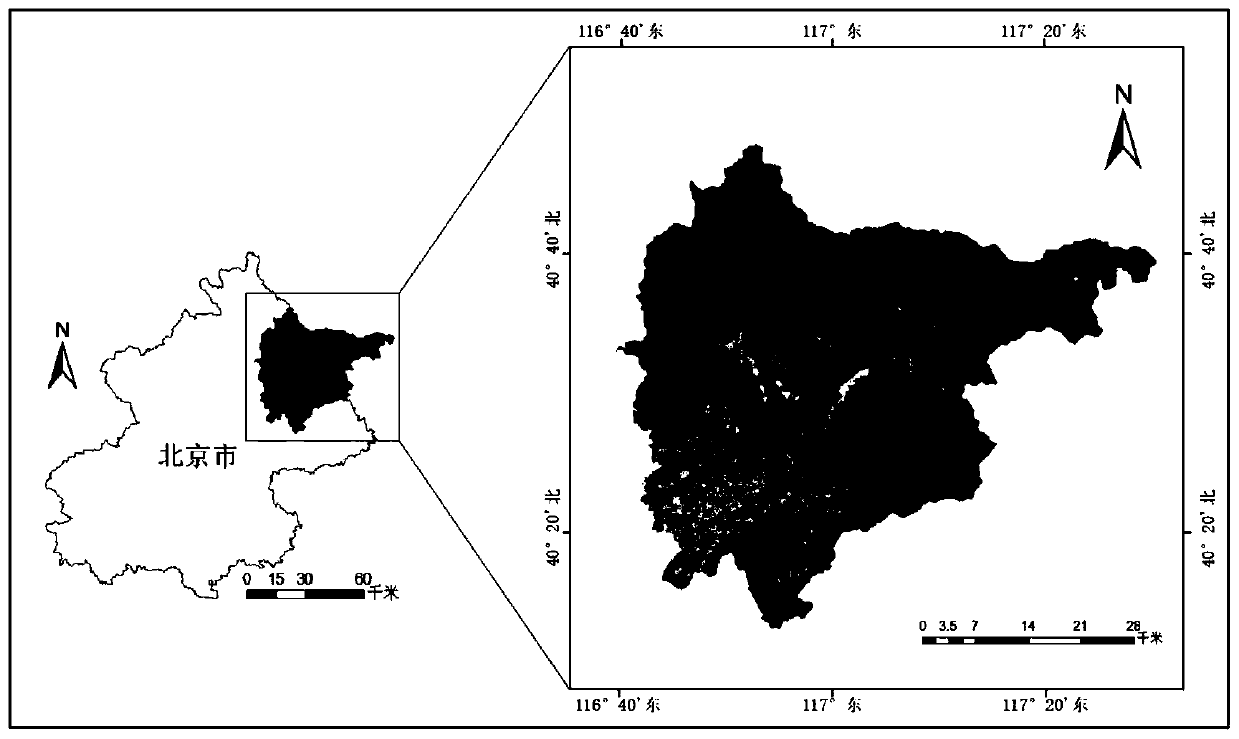

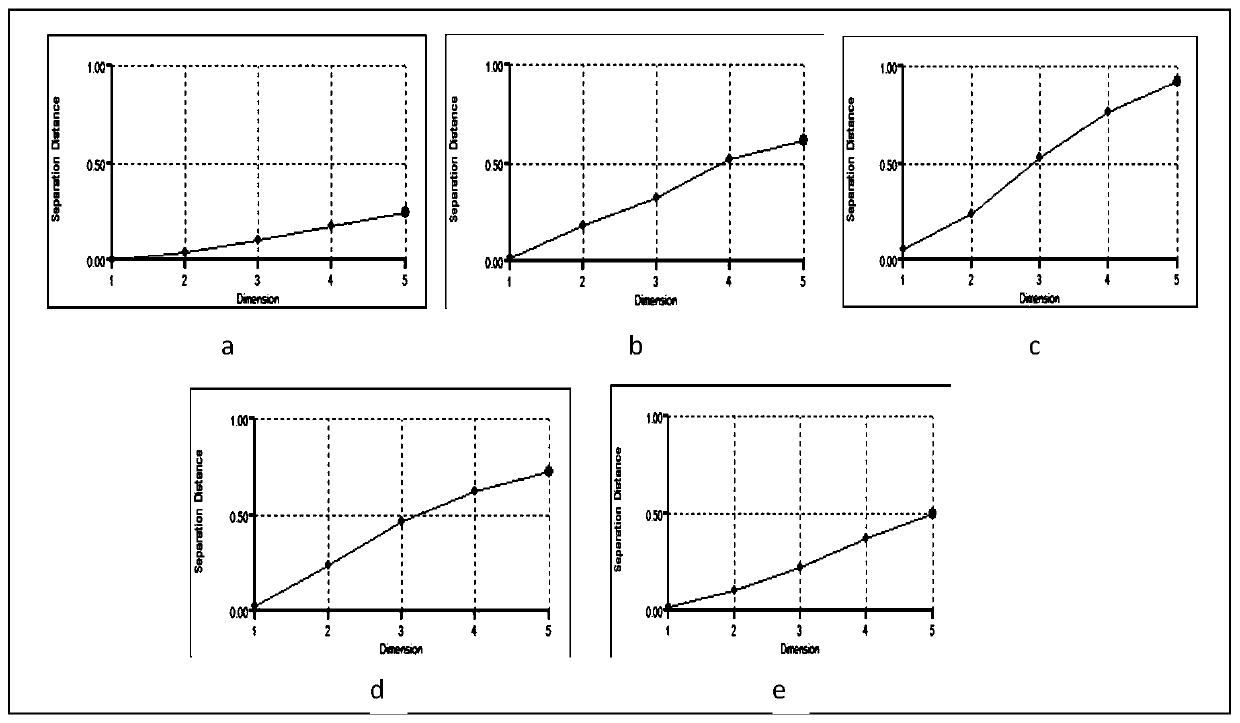

Remote sensing cultivated land change detection method based on object map and mixed spectrum

ActiveCN111598045AImprove detection accuracyHigh precisionScene recognitionFeature extractionMixed spectrum

The invention provides a remote sensing cultivated land change detection method based on an object map and a mixed spectrum. The remote sensing cultivated land change detection method comprises the following steps: step 1, acquiring synchronous remote sensing image data of at least five years; step 2, constructing an object map of the image according to the remote sensing image data; wherein the construction process comprises data preprocessing, image segmentation, feature extraction and image classification; step 3, performing mixed spectrum analysis on the object spectrum; and step 4, detecting the change of the cultivated land through superposition analysis. According to the invention, the difference characteristics of a cultivated land object map and the differentiation characteristicsof mixed spectrum calculation are combined; a corresponding knowledge rule structure is established according to the evolution characteristics of the cultivated land change type, the change of the cultivated land and other ground object types in the change process is described, the detection precision of cultivated land change details is improved, the precision of the whole remote sensing cultivated land change detection method is further improved, and the adaptability of the new detection method is better.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Solar spectrum simulation light source

InactiveCN102487556ASimple structureReasonable designElectrical apparatusElectric lighting sourcesMixed spectrumEffect light

The invention discloses a solar spectrum simulation light source. The light source is formed by a seat body, a halogen tungsten lamp installed on the seat body, an LED white lamp, an LED green lamp and an LED ultraviolet lamp. The LED white lamp, the LED green lamp and the LED ultraviolet lamp form LED lighting set series. The light source has a simple structure. A design is reasonable. Through organically combining the light emitted by the halogen tungsten lamp, the LED white lamp, the LED green lamp and the LED ultraviolet lamp, compared to a xenon lamp spectrum line, a mixed spectrum line is more similar to a solar spectrum line. The solar spectrum can be well simulated. The mixed light source, which accords with practical applications, can be used for making a sun simulator.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

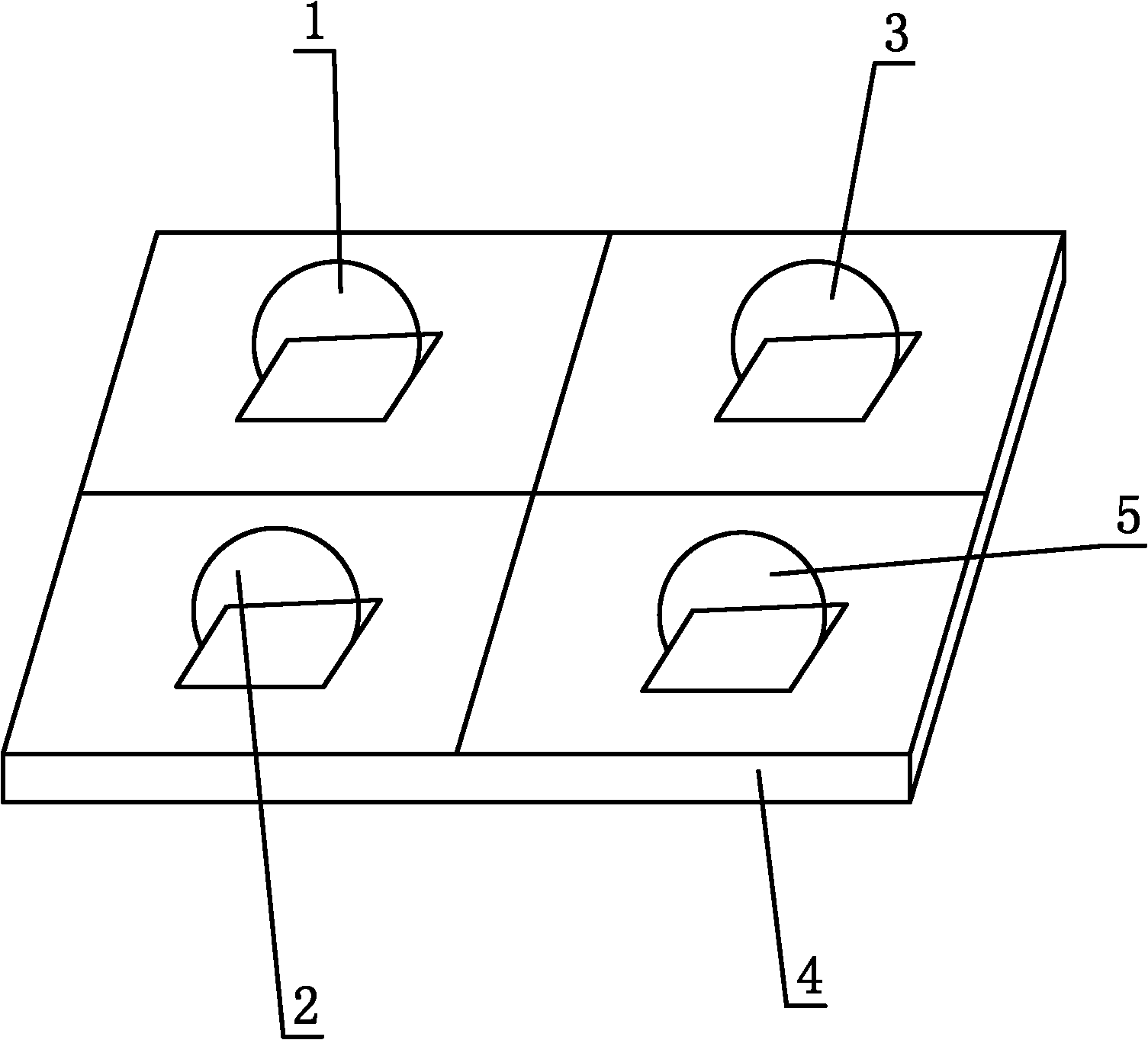

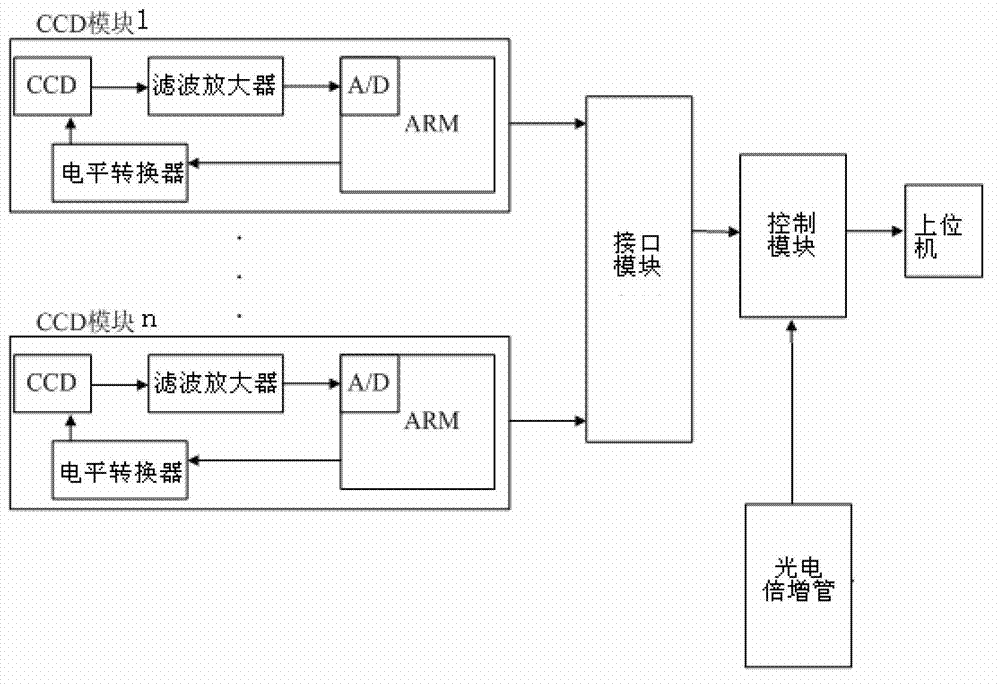

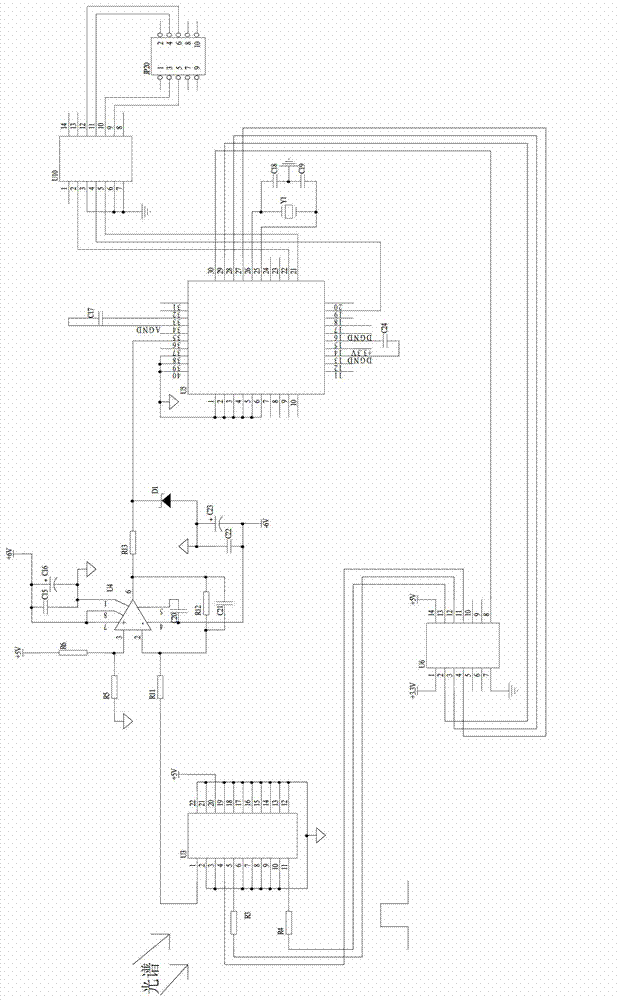

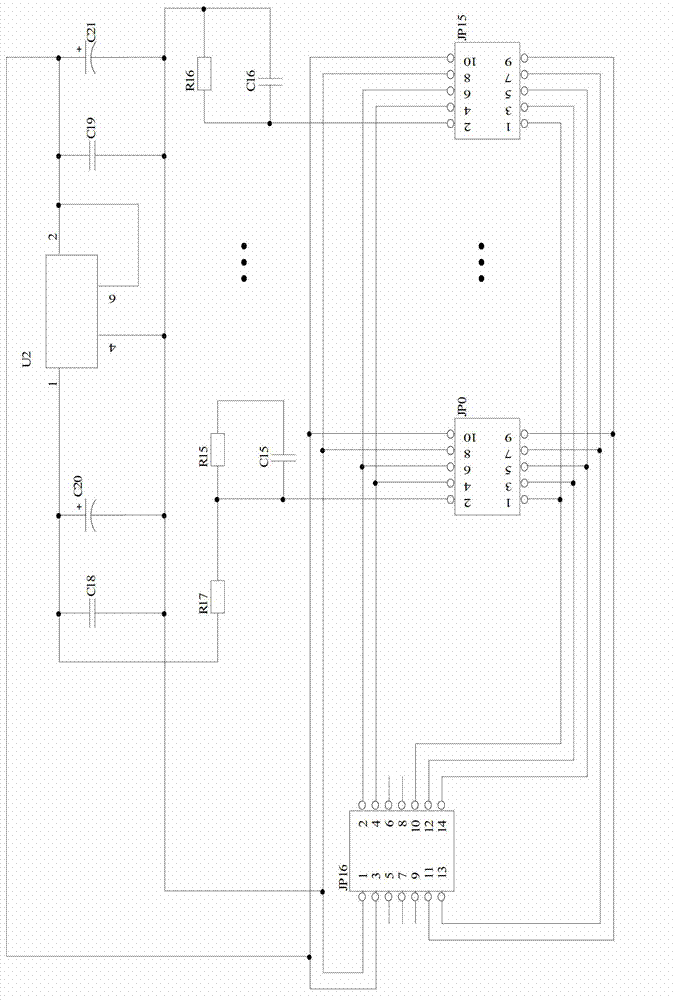

Hybrid spectrometer with charge coupled device (CCD) spectral signal

ActiveCN102967369AImprove integritySimple networkingRadiation pyrometrySpectrum investigationMixed spectrumEngineering

The invention provides a hybrid spectrometer with a charge coupled device (CCD) spectral signal. The hybrid spectrometer comprises a plurality of CCD modules, an interface module, a control module, a photoelectric multiplying tube and an upper computer, wherein the photoelectric multiplying tube is connected with the control module; and the CCD modules are respectively connected with the interface module, the control module and the upper computer sequentially. The hybrid spectrometer has the advantages that the CCD modules are controlled by independent central processing units (CPUs); data and corresponding algorithms can be independently configured; the calculation speed is high, and the algorithms are flexible; and the accuracy and the stability of acquired data are effectively improved. The spectral signal is processed and converted at a front end, so that interference coupling is reduced; and the completeness of the signal is high. The interface module is easy to network and convenient to maintain and debug. The control module seamlessly connects the data acquired by CCDs and the data acquired by the photoelectric multiplying tube; the obtained data are uniformly arranged; the channel data are not distinguished; and analysis software of the upper component is not required to be changed.

Owner:山东东仪光电仪器有限公司 +1

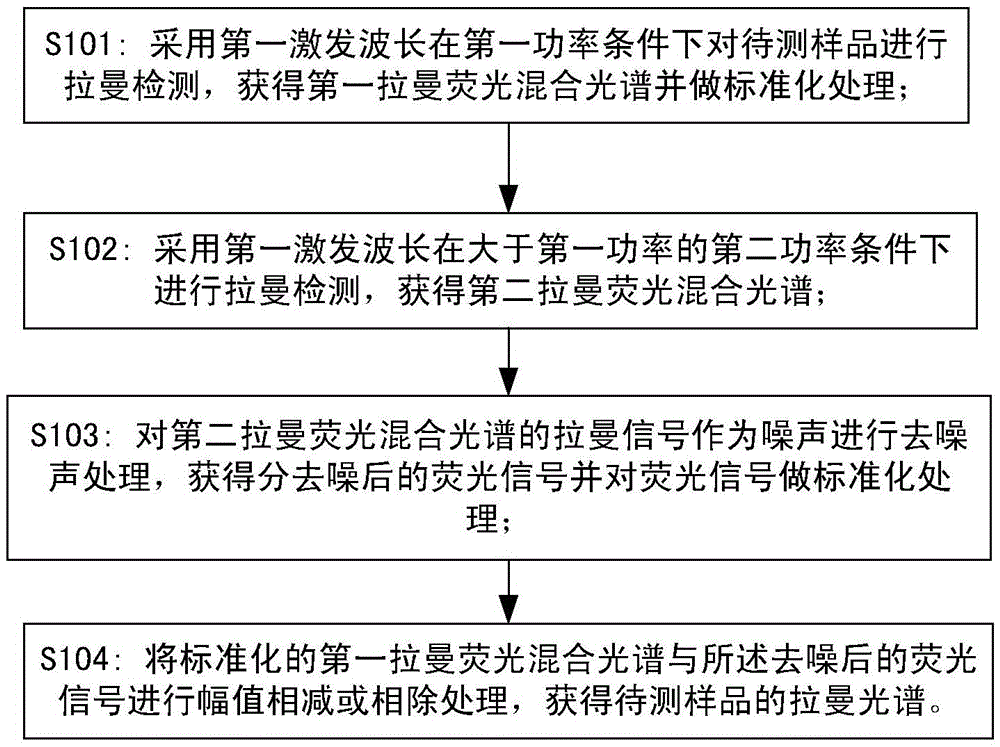

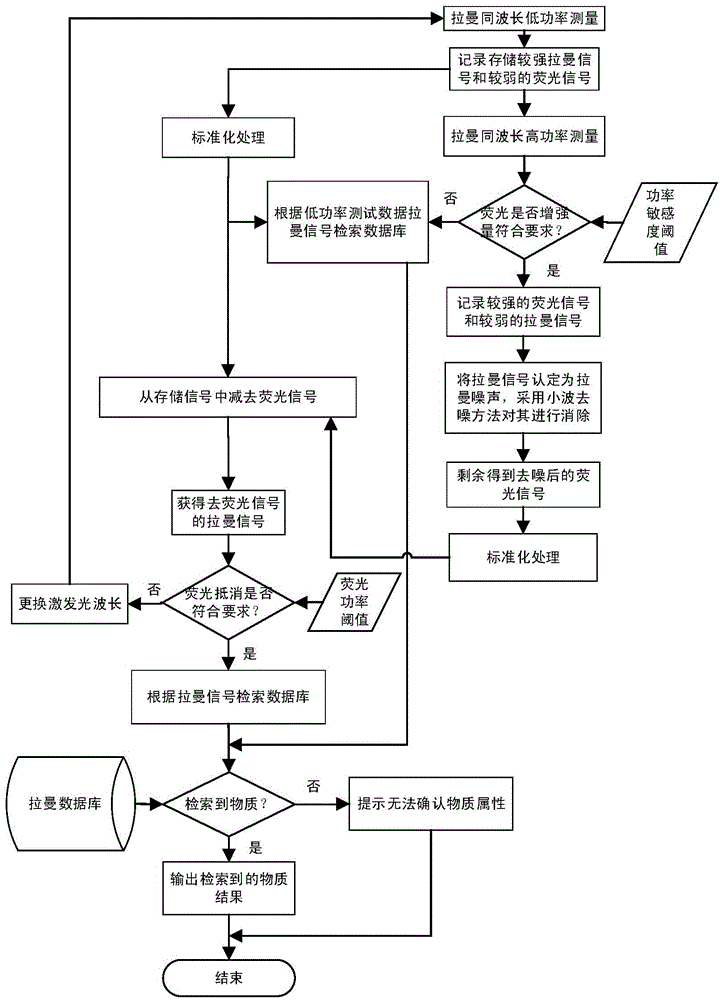

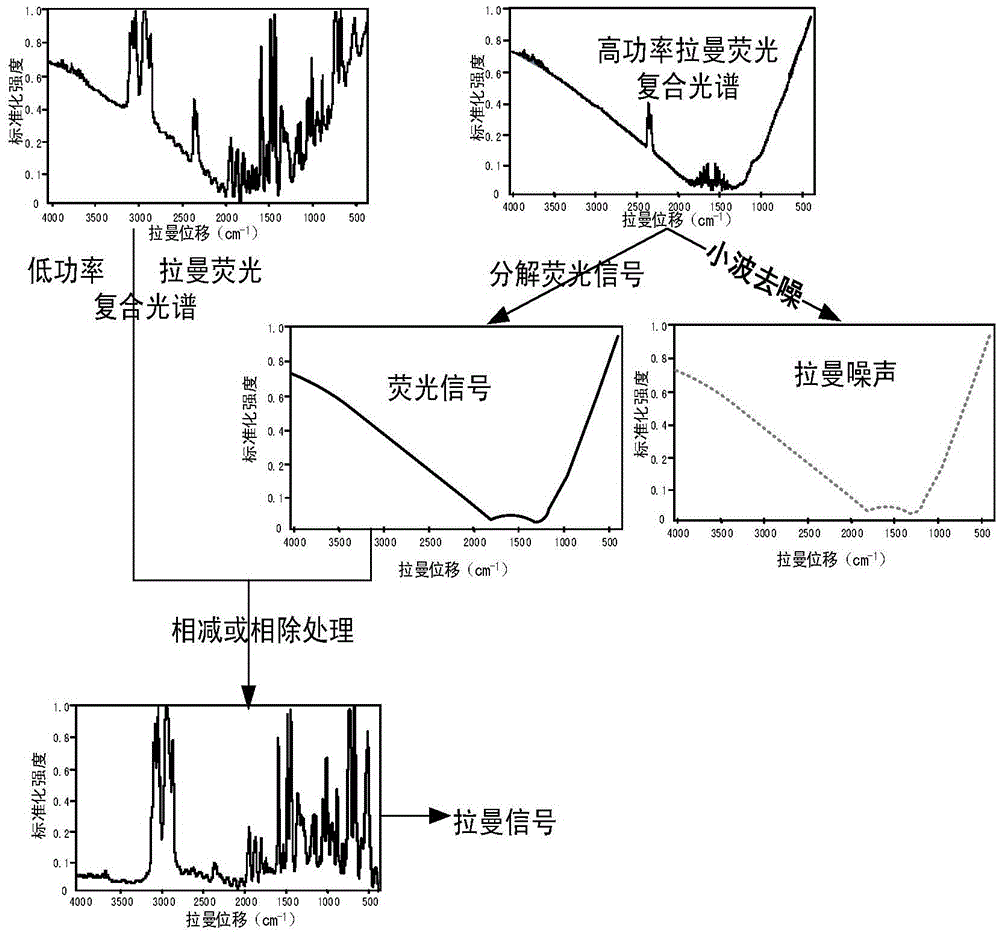

Method for eliminating Raman fluorescence interference of power sensitive substances

The invention provides a method for eliminating Raman fluorescence interference of power sensitive substances. The method is used for solving the problem of fluorescence interference in Raman spectrum measurement and includes the steps that a first Raman fluorescence mixed signal of a to-be-measured sample under the condition of first power is obtained; a second Raman fluorescence mixed spectrum of the to-be-measured sample under the condition of second power larger than the first power is obtained; a Raman signal in the second Raman fluorescence mixed spectrum serves as noise, and is subjected to de-noising processing through a wavelet de-noising mode, and a single fluorescence signal is obtained; a standardized first Raman fluorescence mixed spectrum and the amplitude value of the de-noised fluorescence signal are subjected to fluorescence eliminating processing, and the Raman spectrum of the to-be-measured sample is obtained. By means of the method, the Raman fluorescence interference of the power sensitive substances can be effectively eliminated, and the detection method is simple and reliable.

Owner:BEIJING HTNOVA DETECTION TECH CO LTD

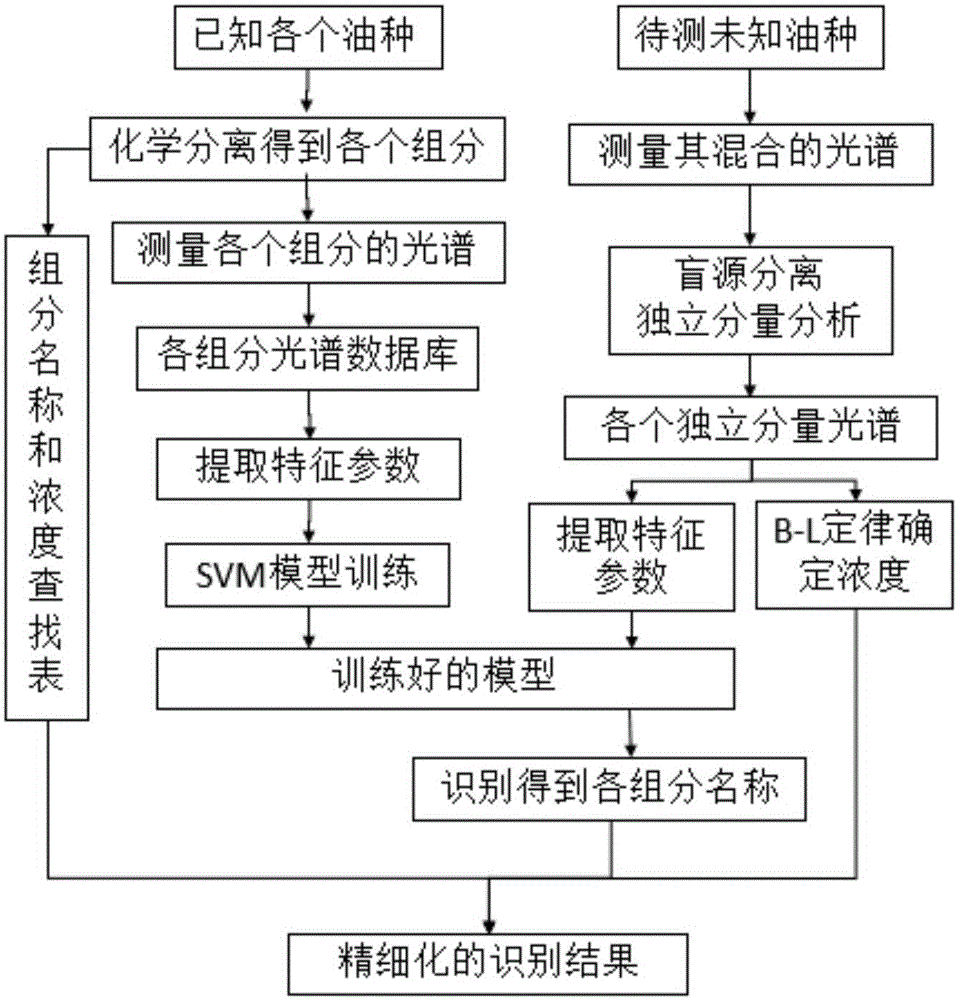

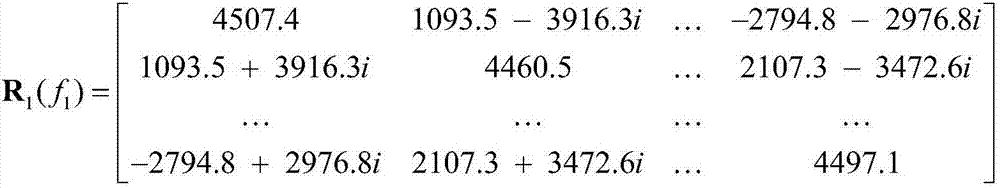

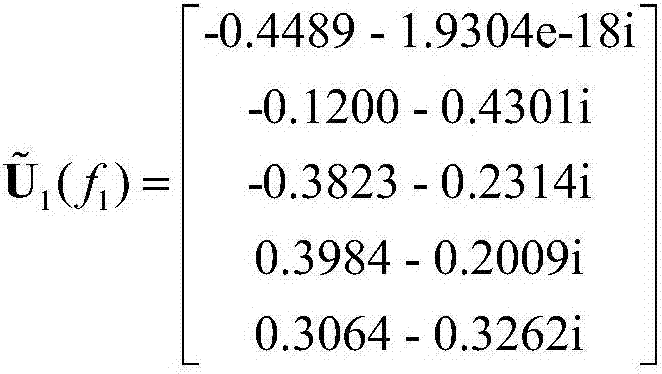

Ocean oil spill fine telemetering method based on blind source separation

InactiveCN105044054ARefined analysisObjective detectionColor/spectral properties measurementsFluorescence/phosphorescenceMixed spectrumBlind signal separation

The invention discloses an ocean oil spill fine telemetering method based on blind source separation. The method includes three processes: a multichannel telemetering system, a mixed spectrum blind signal separation method and spilled oil type recognition method. In the method, a multichannel spectrum observation signal X of a spilled oil sample is obtained through the telemetering system. In the mixed spectrum blind signal separation method, through a quick independent component analysis method, the multichannel spectrum observation signal X is subjected to blind signal separation to obtain a spectrum Y of a plurality of mixed components in the channels respectively, wherein the spectrum Y is the approximation of the main component S in the spilled oil sample and includes hydrocarbons, colloids, asphalts and the content information thereof. The spilled oil type recognition method includes the steps of measuring the characters of the component spectrum, matching the characters of the component spectrum with the spectrum characters of the components in a pattern bank, and further correctly recognizing the components and the contents of the spilled oil. By means of the three steps, the types and the components of the spilled oil can be accurately analyzed, thereby quickly identifying illegal oil spill sources.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

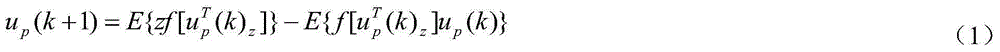

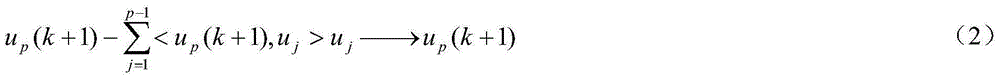

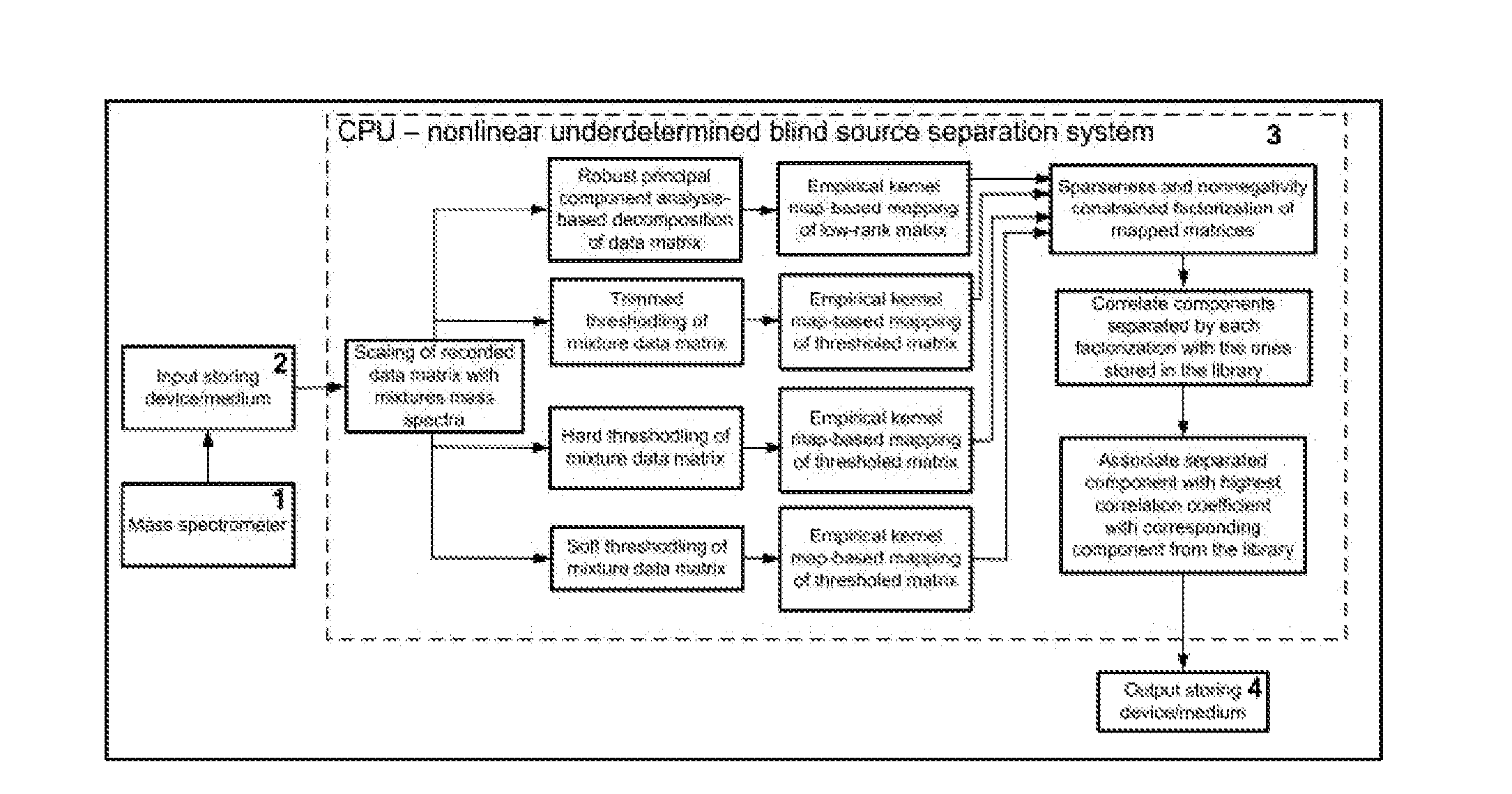

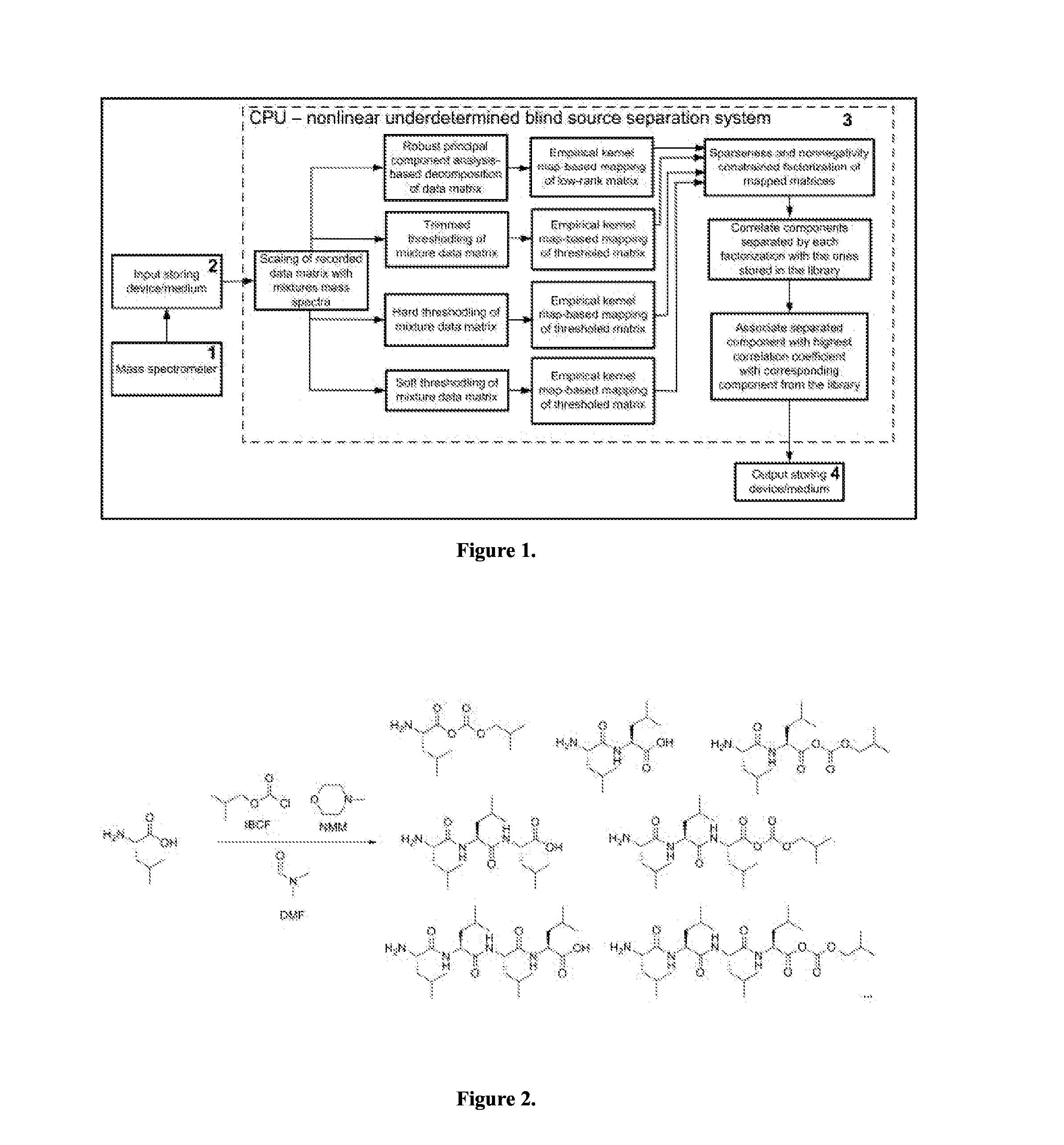

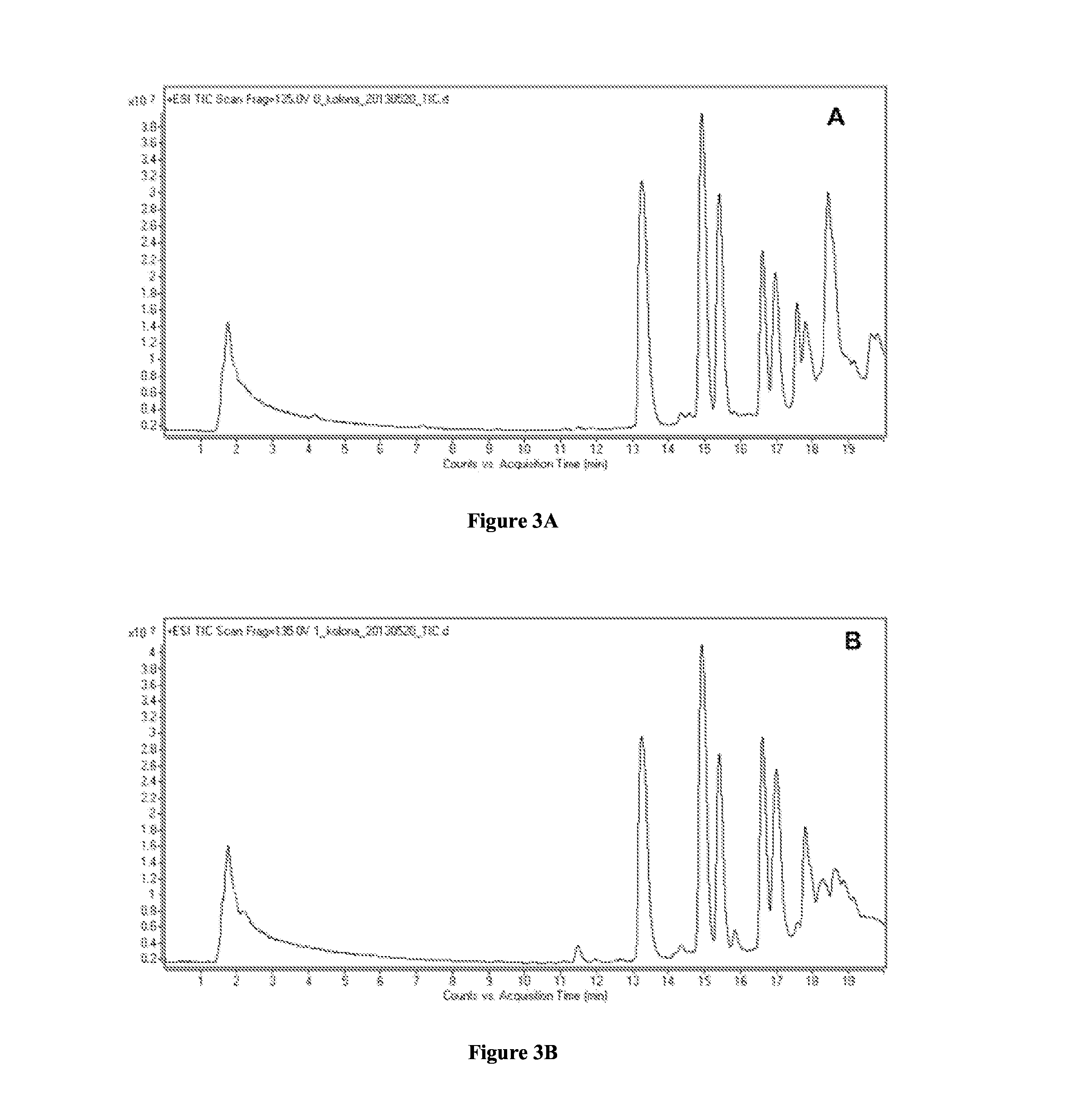

Method and apparatus for underdetermined blind separation of correlated pure components from nonlinear mixture mass spectra

InactiveUS20150206727A1Reduce errorsMass spectrometersBiological testingChemical synthesisNatural source

The present invention relates to a computer-implemented method and apparatus for data processing for the purpose of blind separation of nonnegative correlated pure components from smaller number of nonlinear mixtures of mass spectra. More specific, the invention relates to preprocessing of recorded matrix of mixtures spectra by robust principal component analysis, trimmed thresholding, hard thresholding and soft thresholding; empirical kernel map-based nonlinear mappings of preprocessed matrix of mixtures mass spectra into reproducible kernel Hilbert space and linear sparseness and nonnegativity constrained factorization of mapped matrices therein. Thereby, preprocessing of recorded matrix of mixtures mass spectra is performed to suppress higher order monomials of the pure components that are induced by nonlinear mixtures. Components separated by each factorization are correlated with the ones stored in the library. Thereby, component from the library is associated with the separated component by which it has the highest correlation coefficient. Value of the correlation coefficient indicates degree of pureness of the separated component. Separated components that are not assigned to the pure components from the library can be considered as candidates for new pure components. Identified pure components can be used for identification of compounds in chemical synthesis, food quality inspection or pollution inspection, identification and characterization of compounds obtained from natural sources (microorganisms, plants and animals), or in instrumental diagnostics—determination and identification of metabolites and biomarkers present in biological fluids (urine, blood plasma, cerebrospinal fluid, saliva, amniotic fluid, bile, tears, etc.) or tissue extracts.

Owner:RUDJER BOSKOVIC INST

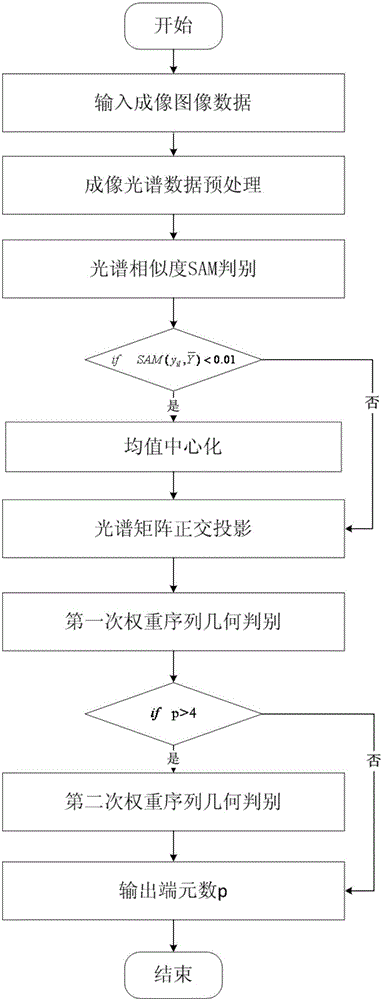

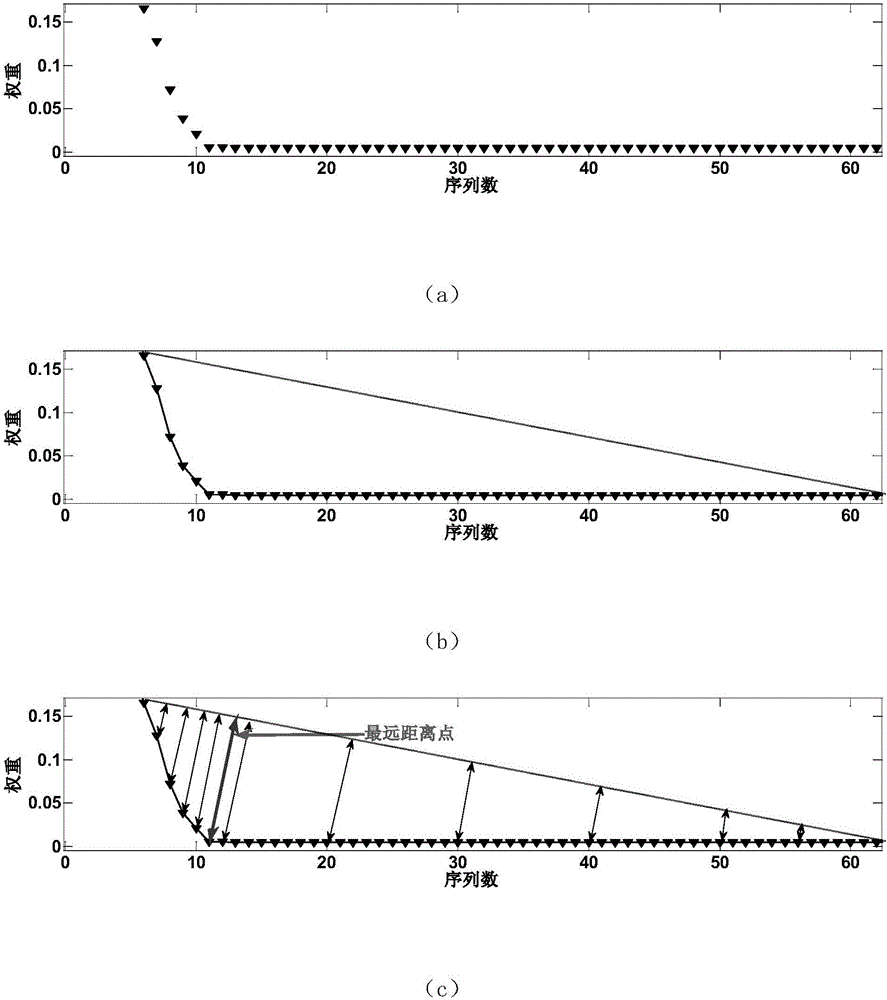

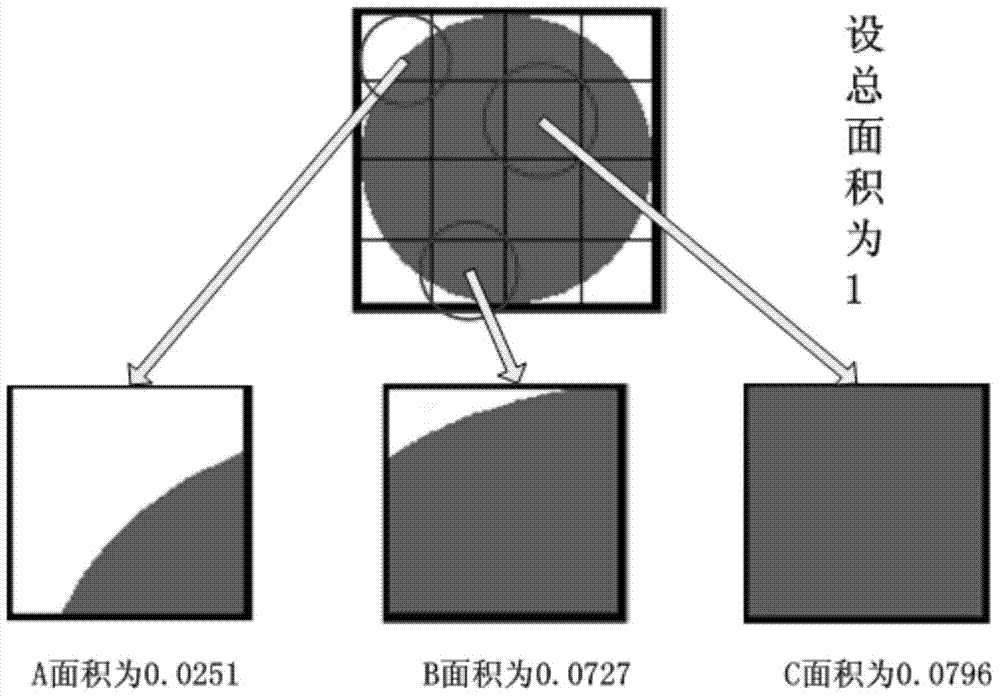

Pure substance quantity determination method in imaging spectrum mixed pixels

ActiveCN105761272AHigh degree of automationEnhance the intensity of spectral informationImage enhancementImage analysisSignal-to-noise ratio (imaging)Mixed spectrum

The invention discloses a pure substance quantity determination method in imaging spectrum mixed pixels, comprising: employing an imaging spectrometer to obtain mixed pixel spectrum data; performing smoothing preprocessing on primary spectra with a lower signal to noise ratio; performing similarity discrimination on obtained pixel spectra, and performing mean centralized processing on primary spectra of higher similarity; simplifying eigenvalue decomposition to project a spectrum matrix onto orthogonal subspaces; descending normalizing obtained subspace eigenvalues to be a weight sequence; and establishing a weight sequence two-dimensional coordinate system, and determining the quantity of mixed pixel pure substances through a geometrical distance automatic distinction mode. The method can efficiently and accurately detect the quantity of mixed pixel pure substances without any prior information, is not only suitable for close range imaging spectra (such as microscopic imaging spectrum) and remote sensing high spectra, but also suitable for grade determination of a non imaging spectrum (such as infrared spectroscopic analysis) black system group.

Owner:BEIHANG UNIV

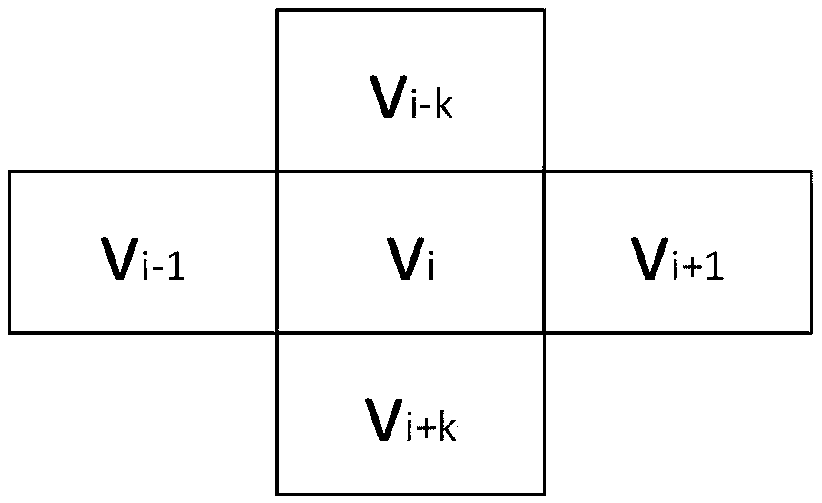

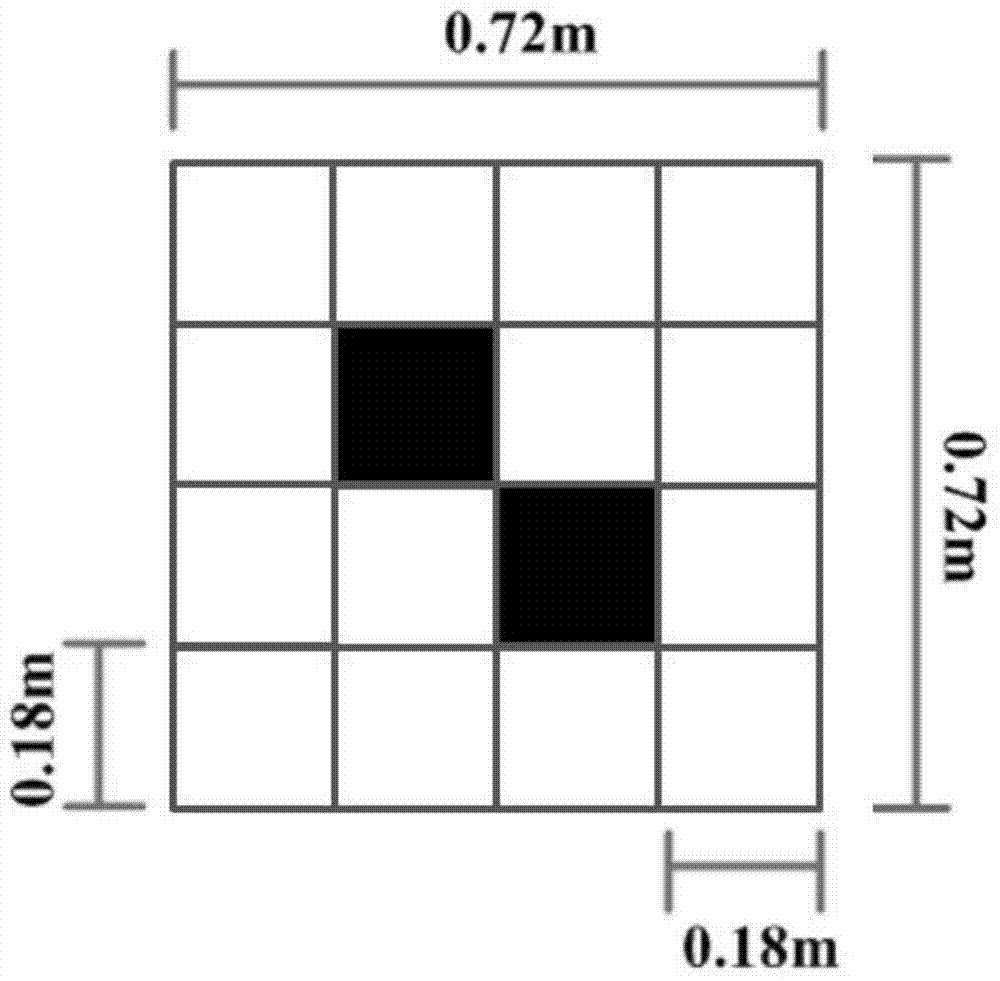

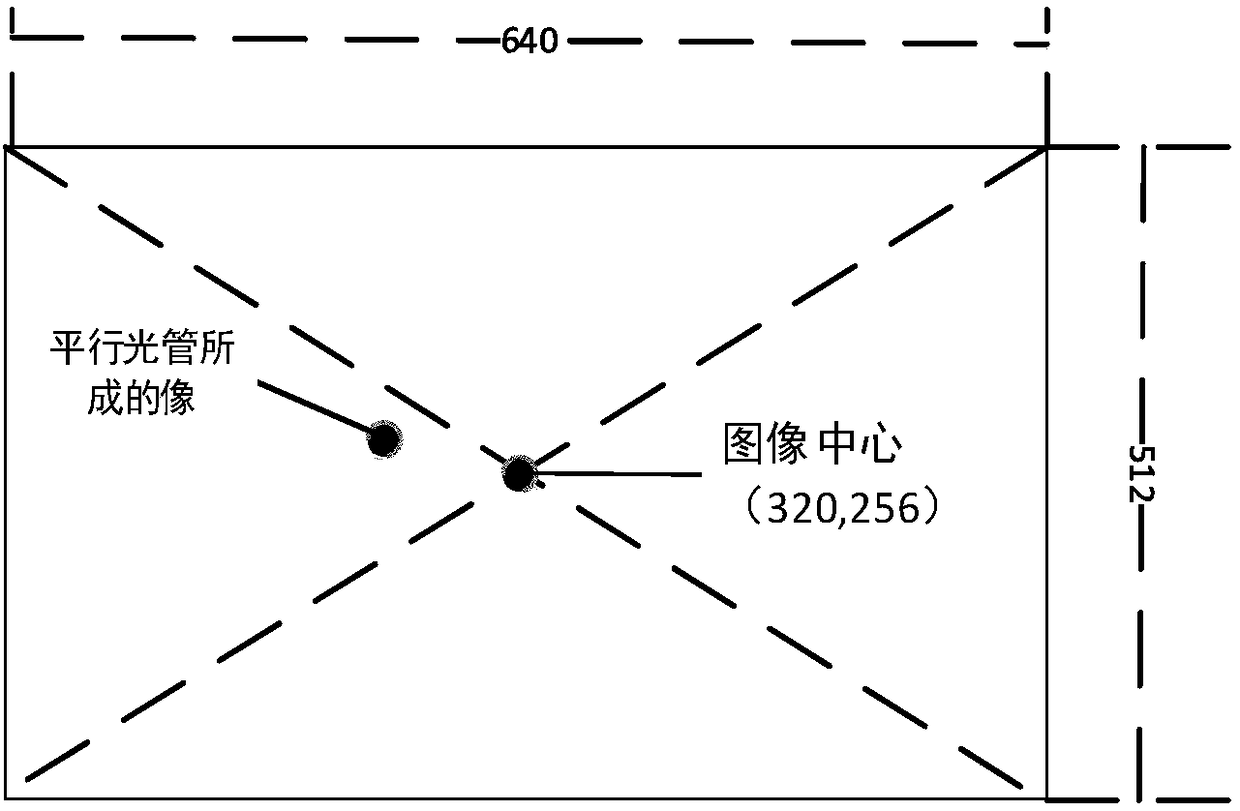

Weld width prediction method before molten pool forming based on mixed spectrum vision

ActiveCN109447939AGood contour effectReduce complexityImage enhancementImage analysisVisual monitoringMixed spectrum

The invention discloses a weld width prediction method before molten pool forming based on mixed spectrum vision, which adopts mixed spectrum imaging to provide rich spectrum dimension information formolten pool, can significantly improve imaging quality of molten pool, and is conducive to improving accuracy of molten pool contour extraction. The method comprises extracting the molten pool contour can obtain the external contour features of the image and prepare for the analysis of the geometric characteristics of the molten pool, which is conducive to the visual monitoring of the welding process from the image. The method of the invention realizes accurate prediction of welding seam width before molten pool forming based on mixed spectrum vision, the monitoring of weld pool can be changed from image visual level to three-dimensional visual perception level. The prediction of weld width can help to observe the changes of weld pool more intuitively and adjust the corresponding weldingparameters to control the welding quality.

Owner:NANJING UNIV OF SCI & TECH

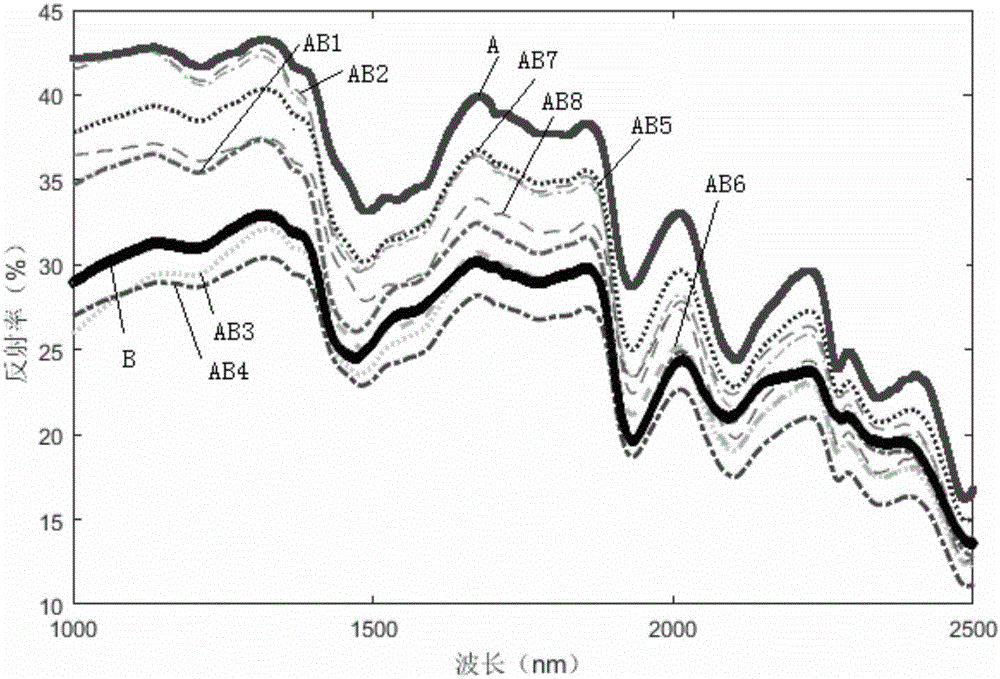

Soil and vegetation mixed spectrum measurement method and simulation system

ActiveCN103499529AClear physical meaningClear featuresColor/spectral properties measurementsVegetationDigital number

The invention discloses a soil and vegetation mixed spectrum measurement method and a simulation system. The system comprises a field spectrograph, an observation zone and a computer processing unit, wherein the field spectrograph is used for observing the DN (digital number) values of a soil and vegetation mixed sample and a reference plate in the observation zone so as to obtain the DN value of the reference plate and the DN value of a mixed pixel spectrograph; the field spectrograph is connected with the computer processing unit through a data line, and calculates the actual reflection rate R of the observation zone according to the DN value of the reference plate and the DN value of the mixed pixel spectrum at different soil and vegetation proportions; the established spectrum mixed model is verified or improved by utilizing the actual reflection rate R of the observation zone, and finally, the spectrum of different soil and vegetation mixed proportions is calculated by utilizing the determined spectrum mixed model. According to the soil and vegetation mixed spectrum measurement method and the simulation system disclosed by the invention, the mixed spectrum research from qualitative to quantitative research development is promoted; the mixed pixel spectrum inversion accuracy is improved; the soil and vegetation mixed spectrum measurement method and the simulation system has important guidance and demonstration significance to the soil and vegetation spectrum inversion at different cover degree conditions.

Owner:PEKING UNIV

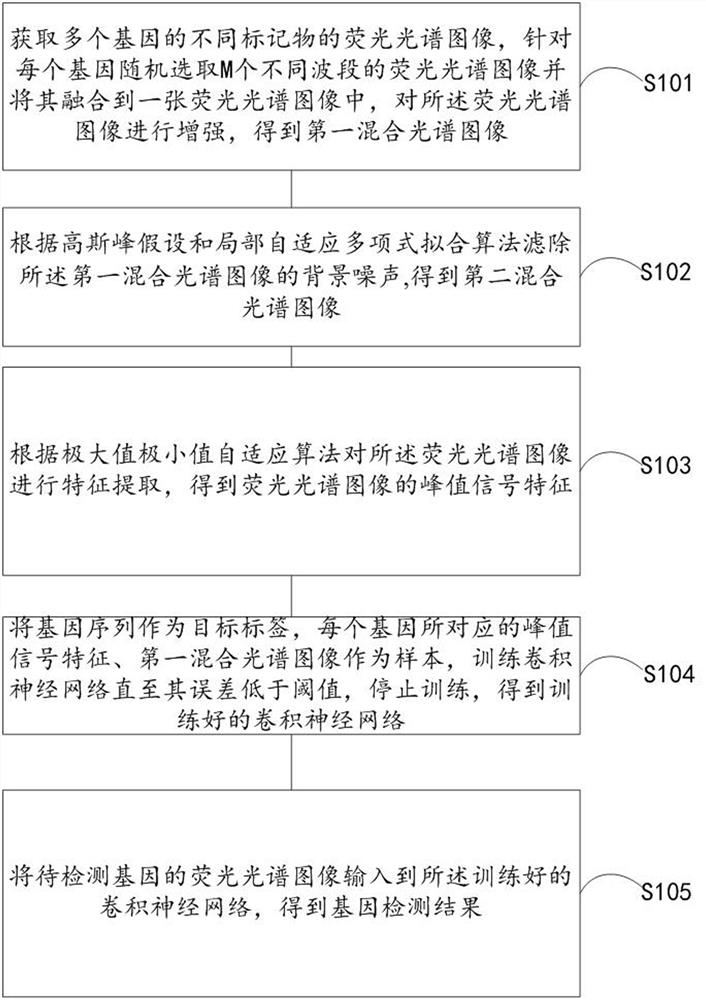

Gene detection method and device based on deep learning and fluorescence spectrum

ActiveCN112309498AImprove signal-to-noise ratioShorten the generation timeImage enhancementImage analysisFluorescent spectraMixed spectrum

The invention relates to a gene detection method and device based on deep learning and fluorescence spectra. The method comprises the steps: acquiring fluorescence spectrum images of different markersof a plurality of genes, randomly selecting M fluorescence spectrum images of different wavebands for each gene, fusing the fluorescence spectrum images into a mixed fluorescence spectrum image, enhancing the fluorescence spectrum images; filtering background noise of the mixed spectrum image according to Gaussian peak hypothesis and a local adaptive polynomial fitting algorithm, and then performing feature extraction on a second mixed spectrum image according to a maximum value and minimum value adaptive algorithm to obtain peak signal features of the fluorescence spectrum images; and training a convolutional neural network model according to the data, and acquiring a gene detection result by using the convolutional neural network model. According to the method, traditional filtering andimage processing are combined, and the feature extraction is carried out on the fluorescence spectrum images; and the fluorescence spectra of different markers in the sample improve the robustness, generalization ability and accuracy of the convolutional neural network model.

Owner:WUHAN NEUROPHTH BIOTECHNOLOGY LTD CO

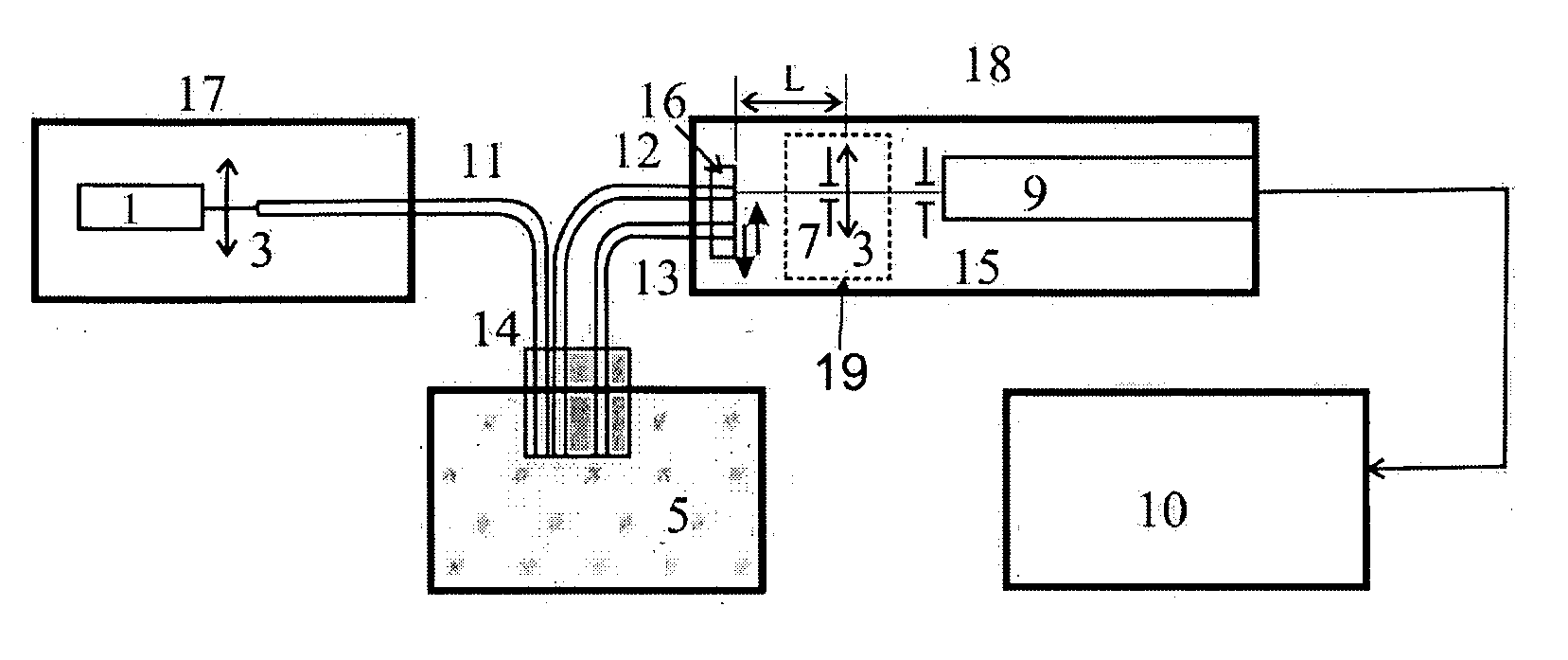

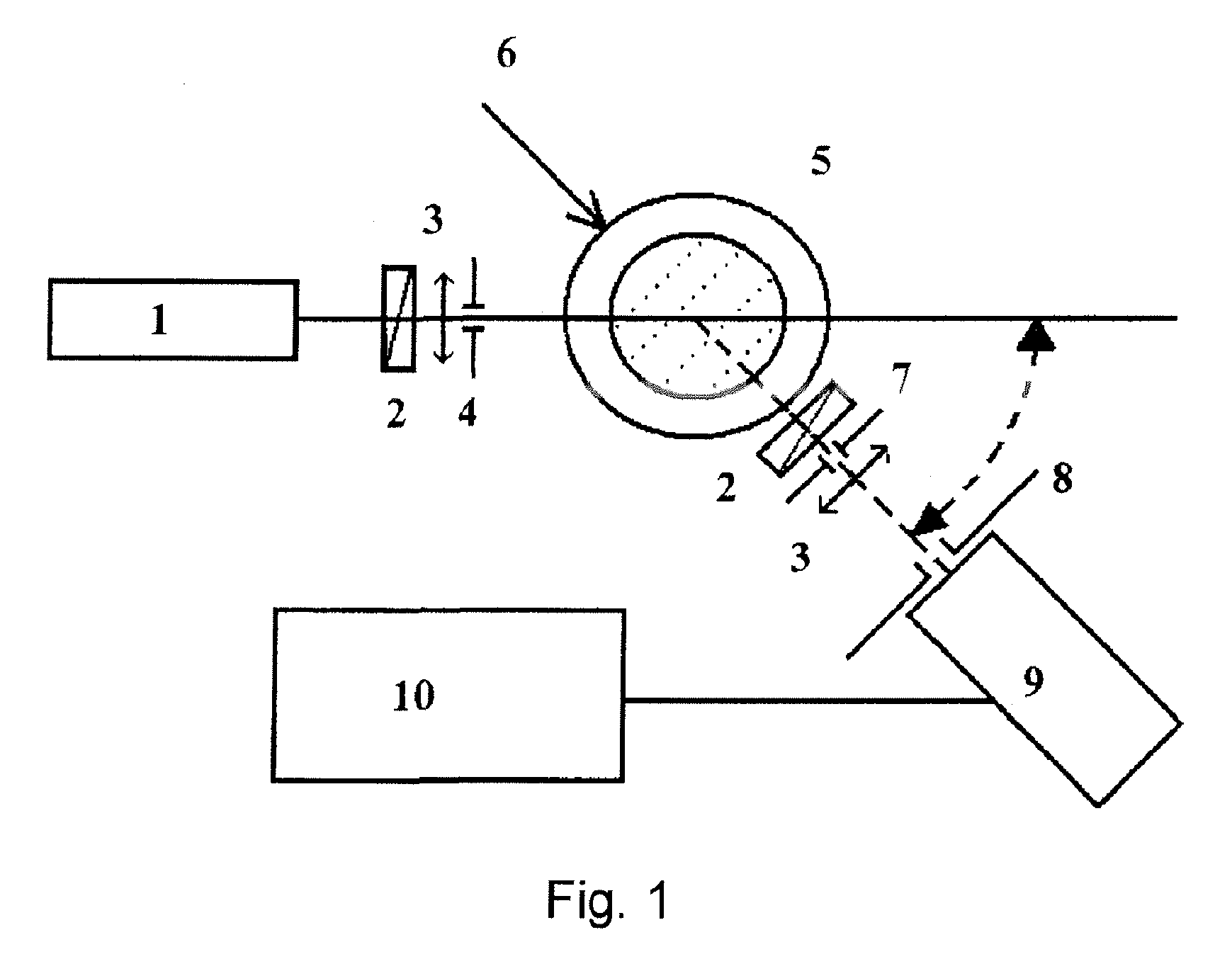

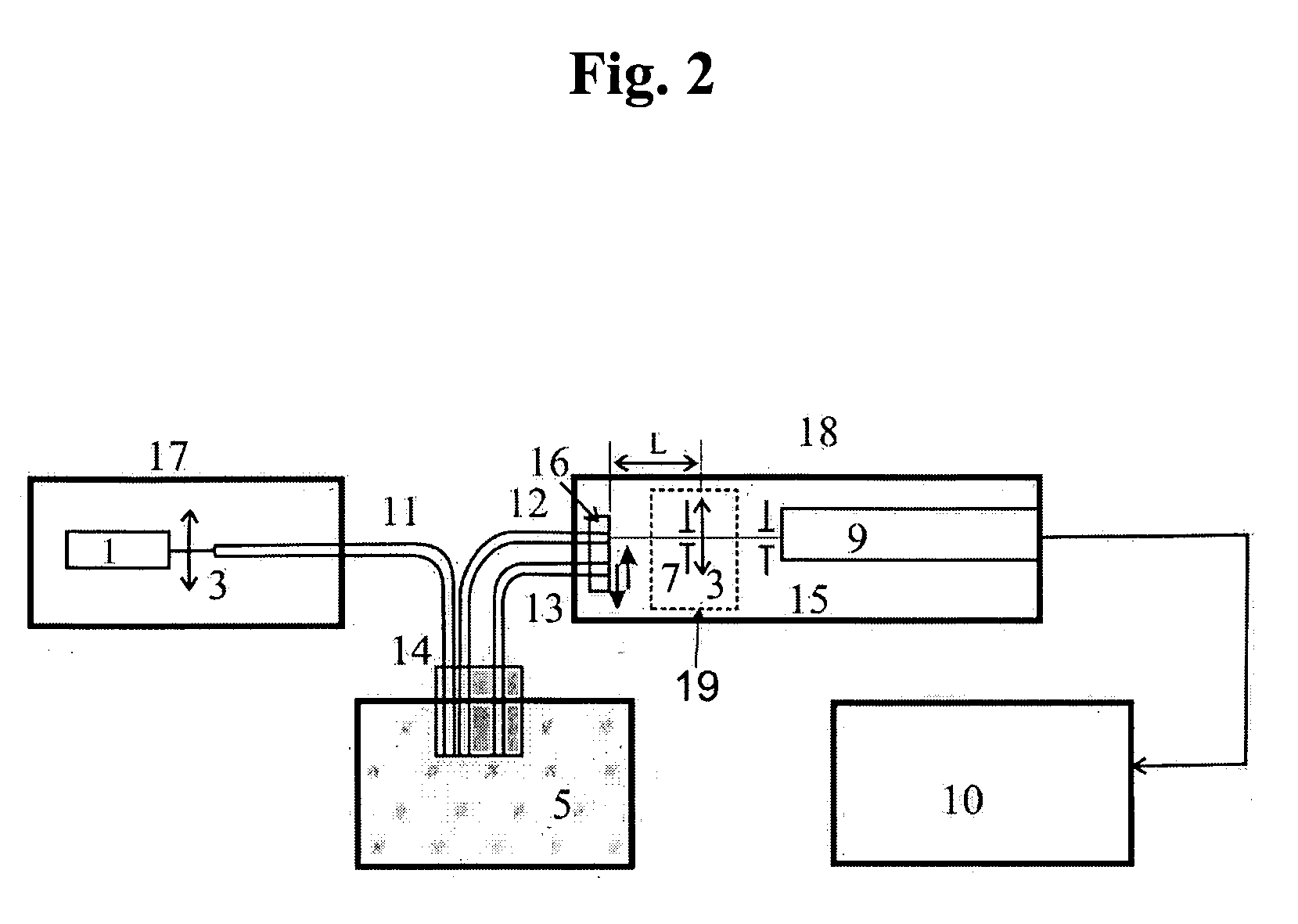

Method and apparatus for measuring particle sizes in a liquid field of the invention

InactiveUS20090213372A1Material analysis by optical meansParticle size analysisWorking fluidPetroleum product

The invention relates to processes for measuring and controlling particle sizes in micro- and nanoemulsions, colloidal solutions and suspensions of particles in liquids and gases. The invention is applicable in chemical processes, in particular, in petrochemistry, transportation of petroleum products, oil and gas, in food and medical industries, medical research, for producing nanoparticles for electronic and electrical industry, controlling the state of operating fluids in mechanical and power engineering, i.e. for controlling the processes for producing or using colloidal solutions, emulsions and suspensions of solid or liquid particles.A new method of measuring sizes of particles suspended in a liquid using optical mixing spectroscopy of scattered light and an apparatus for implementing the method are disclosed. The method consists in making measurements by a fiber optic probe introduced into a medium under investigation, the probe comprising several multiple or single mode optical fibers. One of the optical fibers transmits light into the medium, while the other optical fibers transmit scattered light to a device for providing spatial coherence of the light and then to a light detector. Auxiliary optical fibers are used to determine the relationship between spectral line widths of multiple and single light scattering when measurements are conducted in very turbid media and for determining particle sizes from multiple rather than single scattering spectrum. The attained technical result is that the method does not require the use of single mode optical fibers and integrated optics, and placing a suspension sample into an optical cell as it is common in conventional methods. The method exhibits an enhanced immunity to interference caused by dust in the sample. Therefore the invented method enables particle size measurements both in laboratory cells and test tubers, and directly in pipelines of production units, barrels, tanks and other reservoirs with finished product, chemical reactors, canisters and trays of machining tools, etc. The method can be used both invasively and noninvasively, i.e. for studying a medium through a transparent window.

Owner:FEDERALNOE GOSUDARSTVENNOE BJUDZHETNOE UCHREZHDENIE NAUKI FIZICHESKIJ INST IM P N LEBEDEVA ROSSIJSKOJ AKADI NAUK FIAN

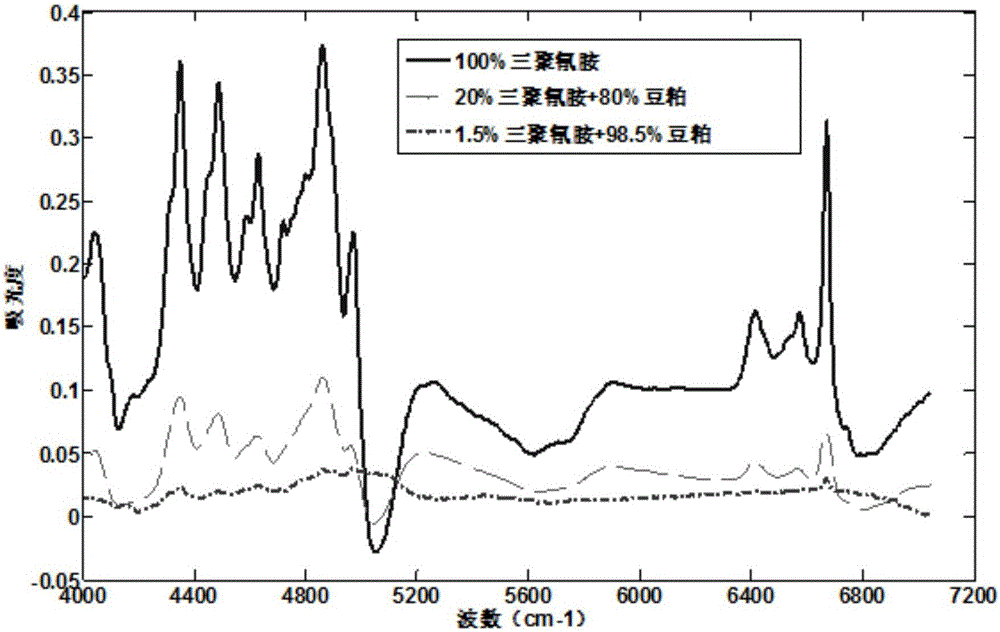

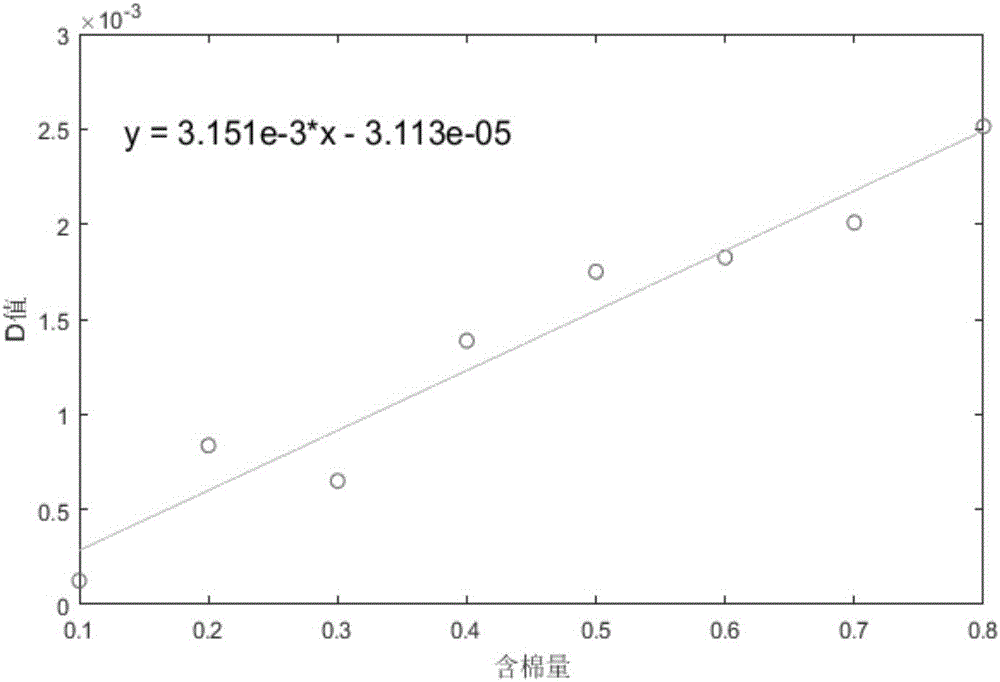

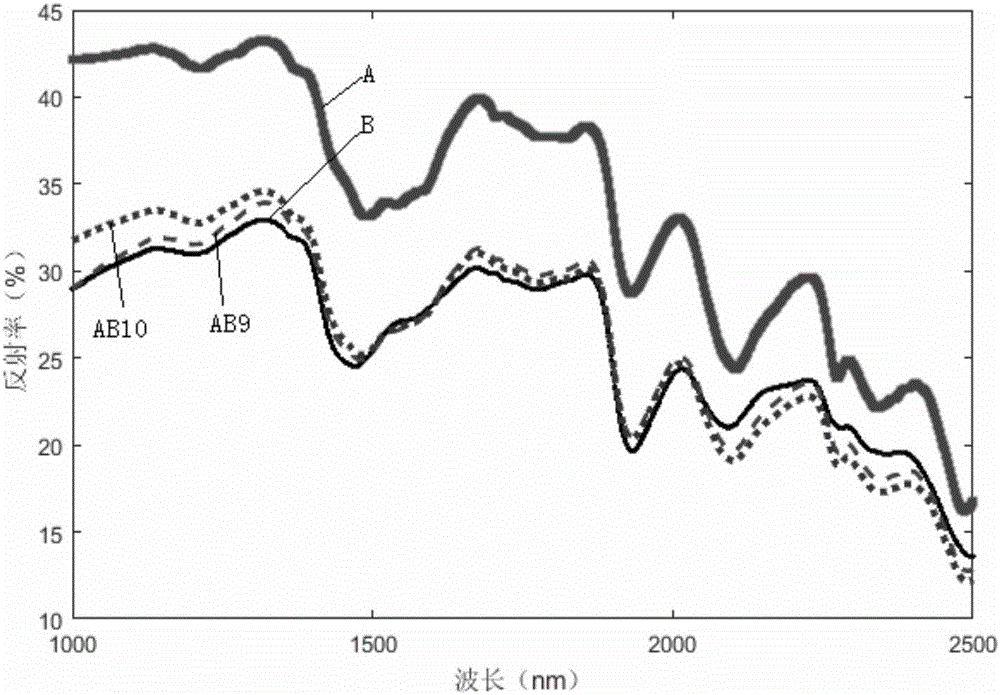

Method for direct quantitative measurement of binary mixed system by near infrared spectrum

Relating to a measurement method of a binary mixed system in the optical field, the invention provides a method for direct quantitative measurement of binary mixed system by near infrared spectrum. The method includes: collecting the near infrared spectrum of each component, establishing a moving window, selecting a near infrared spectrum B of a component b, moving the moving window from the left end of the near infrared spectrum B to the right, calculating the angle of the near infrared spectrum B and the angle of a near infrared mixed spectrum AB respectively to obtain a series of angle values, and calculating a variance D of the series of angle values; calculating the series variance Di of the near infrared spectrum B and a near infrared mixed spectrum AB under different content of the component b respectively; drawing a standard curve of different content of the component b and the series variance Di, and according to the standard curve, determining the ratio of component a and component b in the to-be-measured binary mixed system ab, thus realizing component quantification of the measured object. The method provided by the invention has the characteristics of simplicity, low cost, and low work intensity, can realize quantification without following a strict photometric value.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

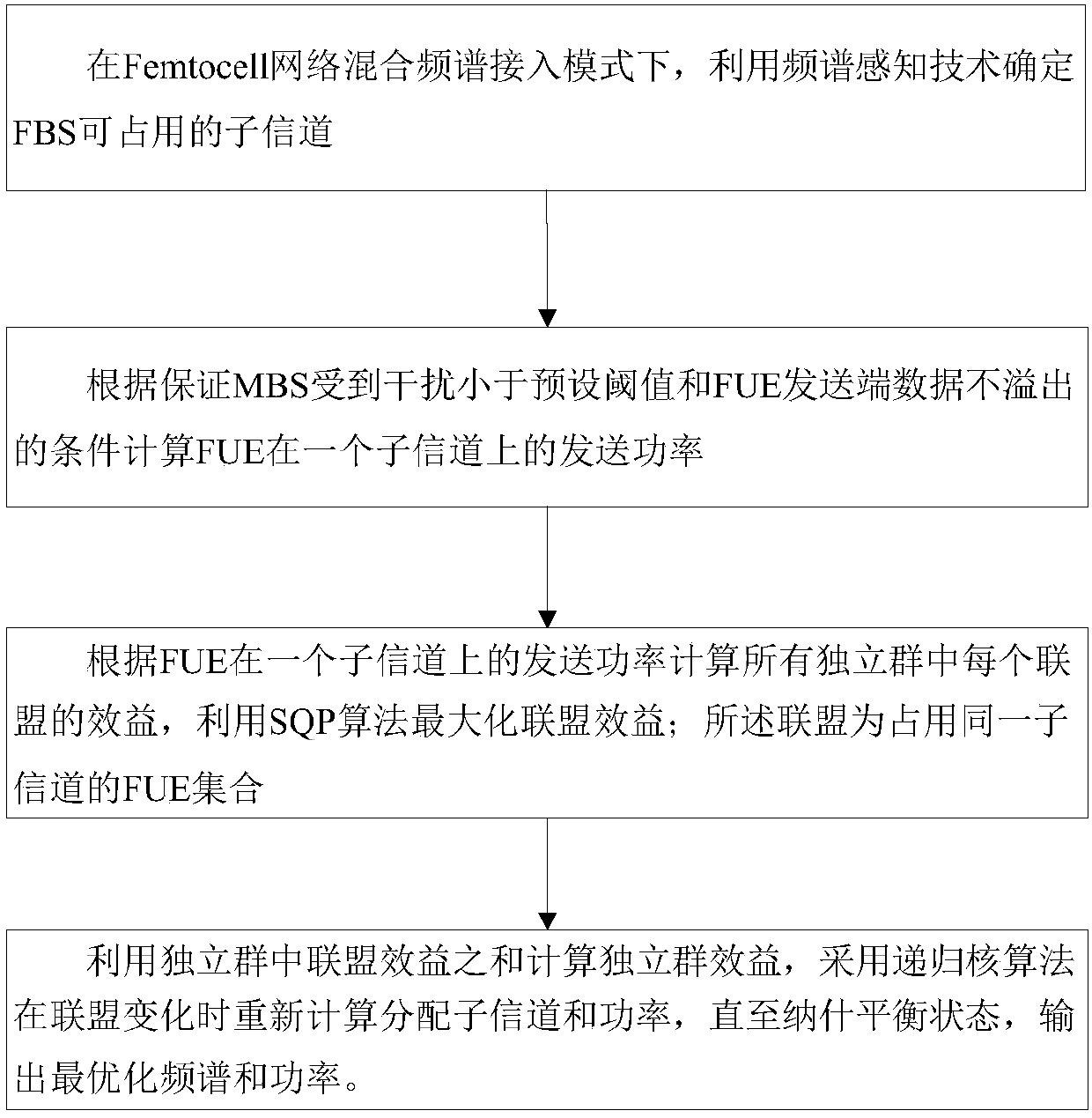

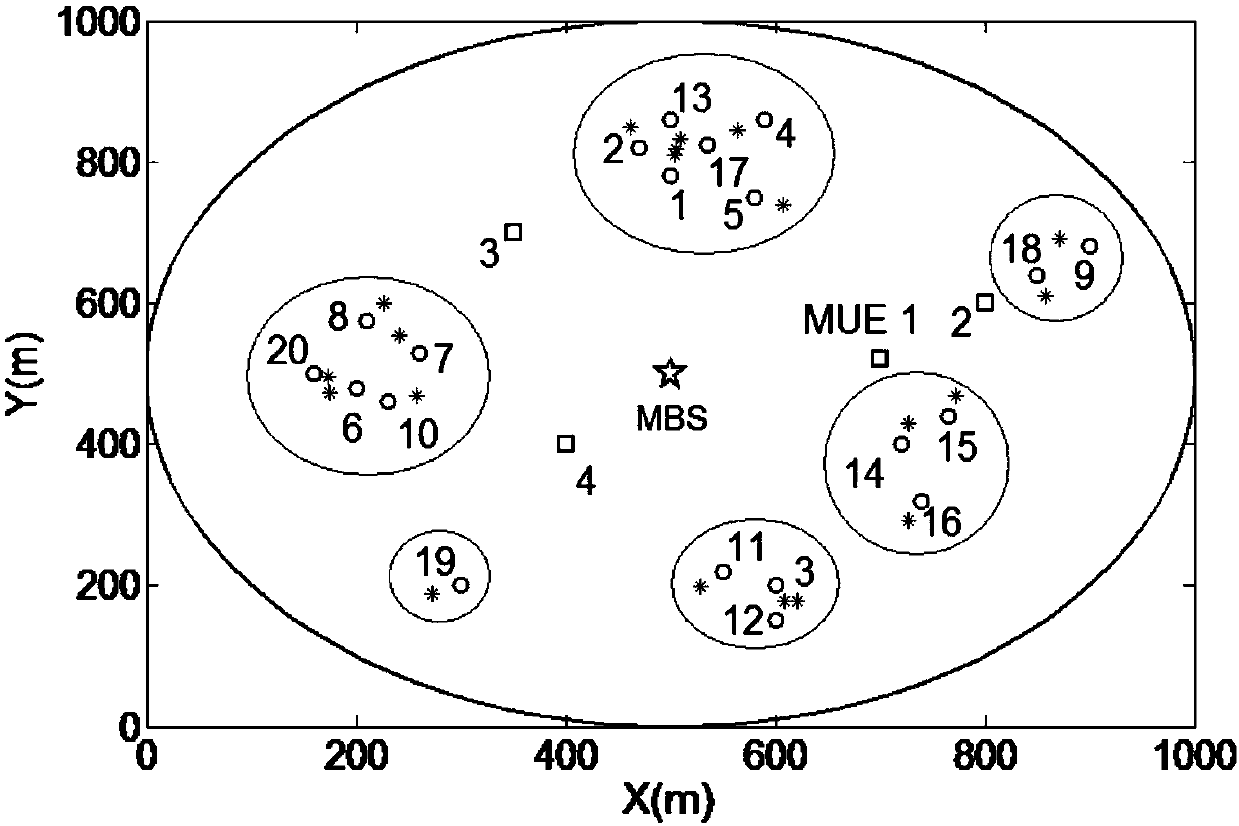

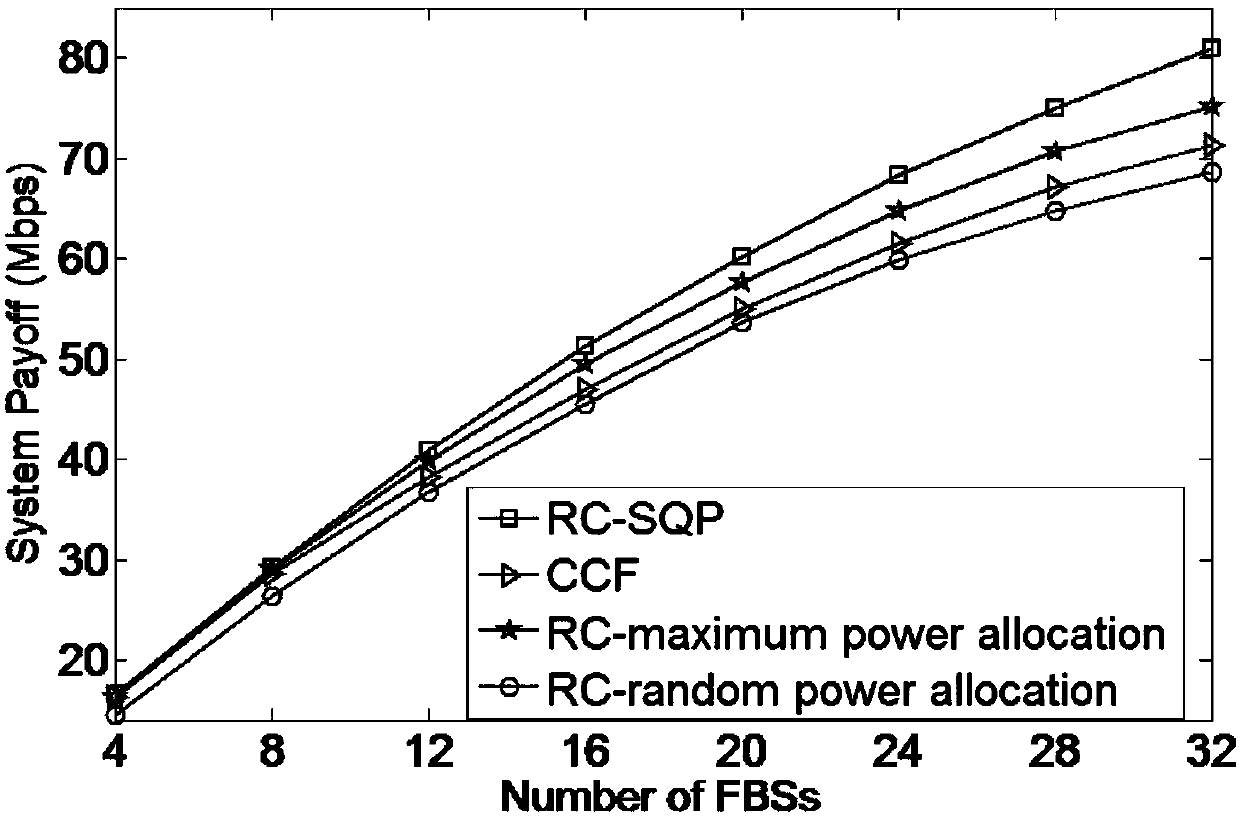

Spectrum and power allocation method, device and system for Femtocell network

InactiveCN108616996AImprove throughputBenefits are not compromisedTransmission monitoringWireless communicationMixed spectrumFrequency spectrum

The invention discloses a spectrum and power allocation method, device and system for a Femtocell network. The spectrum and power allocation method comprises the steps of determining sub-channels capable of being occupied by an FBS (Femtocell Base Station) by using a spectrum sensing technology in a mixed spectrum access mode of the Femtocell network; calculating the transmitting power of FUE (Femtocell User Equipment) on one sub-channel according to the conditions that the interference received by the MBS is ensured to be less than a preset threshold and that transmitting terminal data of theFUE does not overflow; calculating the benefit of each alliance in all independent groups according to the transmitting power of the FUE on one sub-channel; and maximizing the alliance benefit by using an SQP algorithm, wherein the alliance is an FUE set occupying the same sub-channel; calculating the benefit of each independent group by using the sum of the alliance benefits in each independentgroup, calculating the allocated sub-channel and power again when the alliance changes by adopting a recursive accounting method until a Nash equilibrium state, and outputting the optimal spectrum andpower.

Owner:SHANDONG UNIV

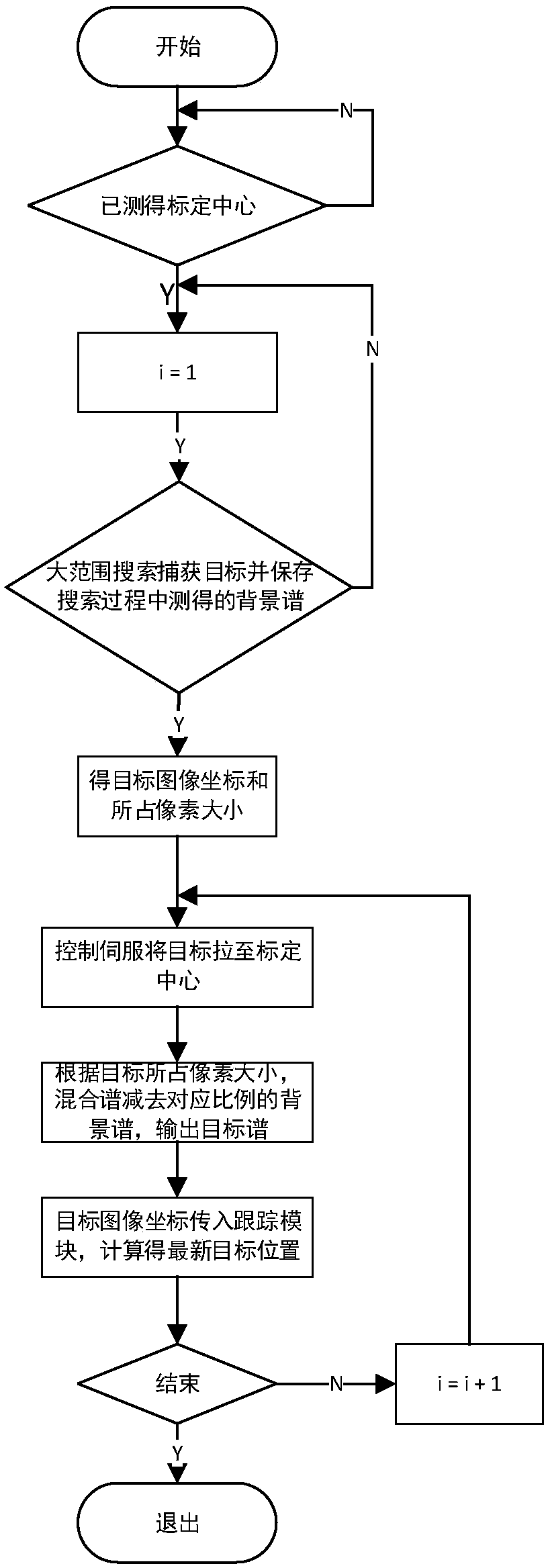

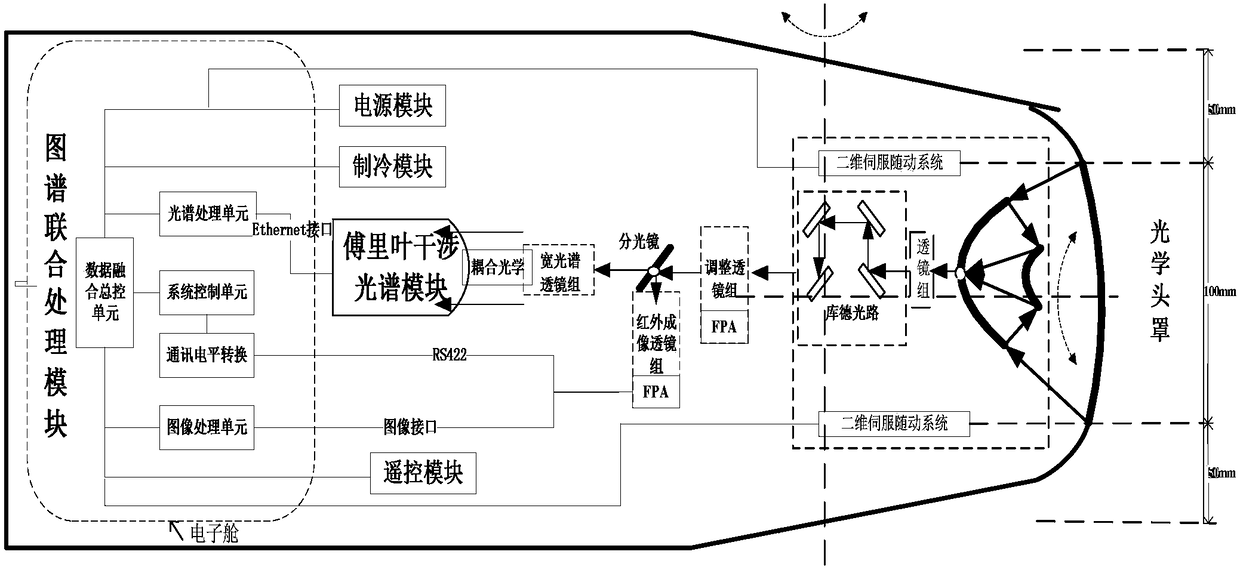

Accurate spectrum measuring method for moving target

ActiveCN108305290AAvoid difficultiesReduce the impactImage analysisSpectrum investigationSpectral responseBackground spectrum

The invention discloses an accurate spectrum measuring method for a moving target. The method comprises the steps that (1) a point with the greatest spectral response on the imaging image surface of amap correlation detection system is determined, and the point is set as a calibration center; (2) the target is searched and captured in a large range; on one hand, the background spectrum measured during the search process is recorded; on the other hand, the target is captured, and if the target is captured, the image coordinate of the target and the number of pixels occupied by the target are determined until the target is captured; (3) according to the distance between the image coordinate of the target and the calibration center, the control of a servo mechanism is used to quickly pull the target to the calibration center to measure the spectrum of the target at the position of the calibration center; and (4) according to the number of pixels occupied by the target in the step (2), the proportion of the background in a spectrum measuring range is determined, and the background spectrum is subtracted from the mixed spectrum acquired by the map correlation detection system accordingto the proportion of the background to acquire the target spectrum. According to the invention, the accurate target spectrum can be acquired.

Owner:HUAZHONG UNIV OF SCI & TECH

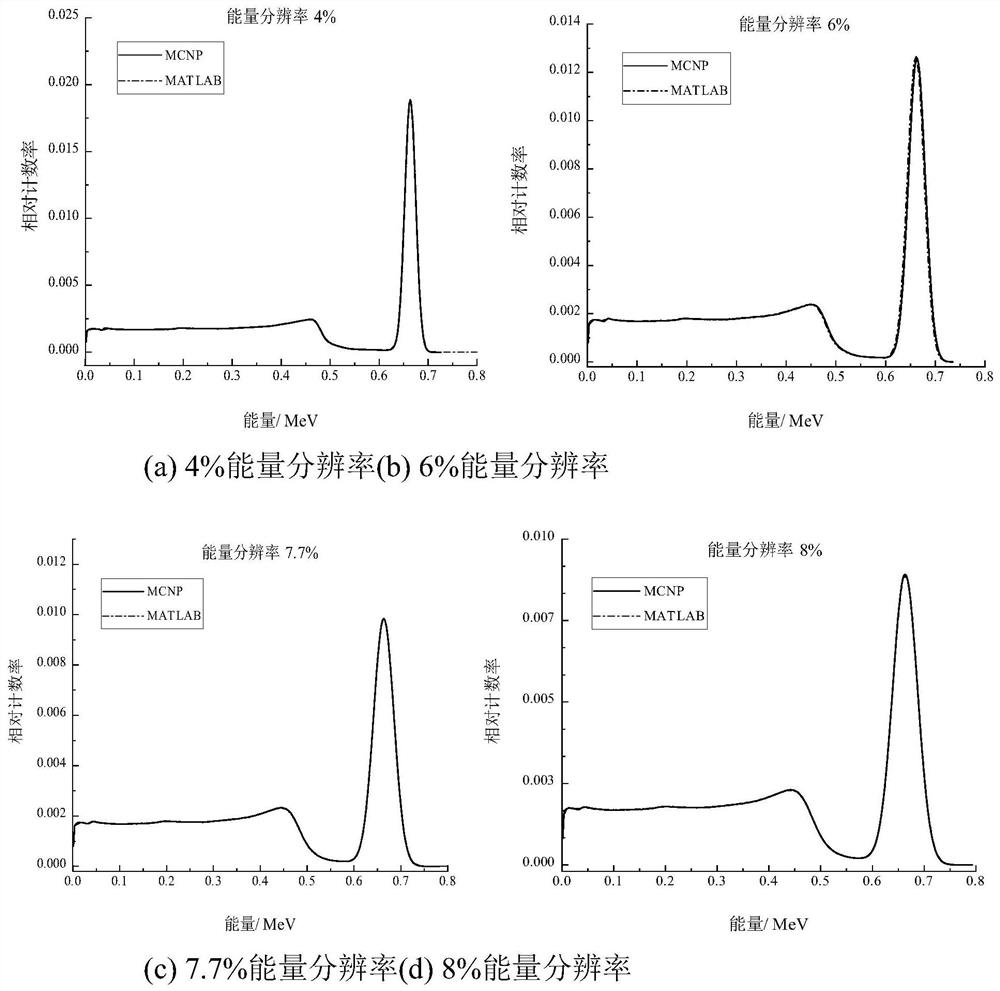

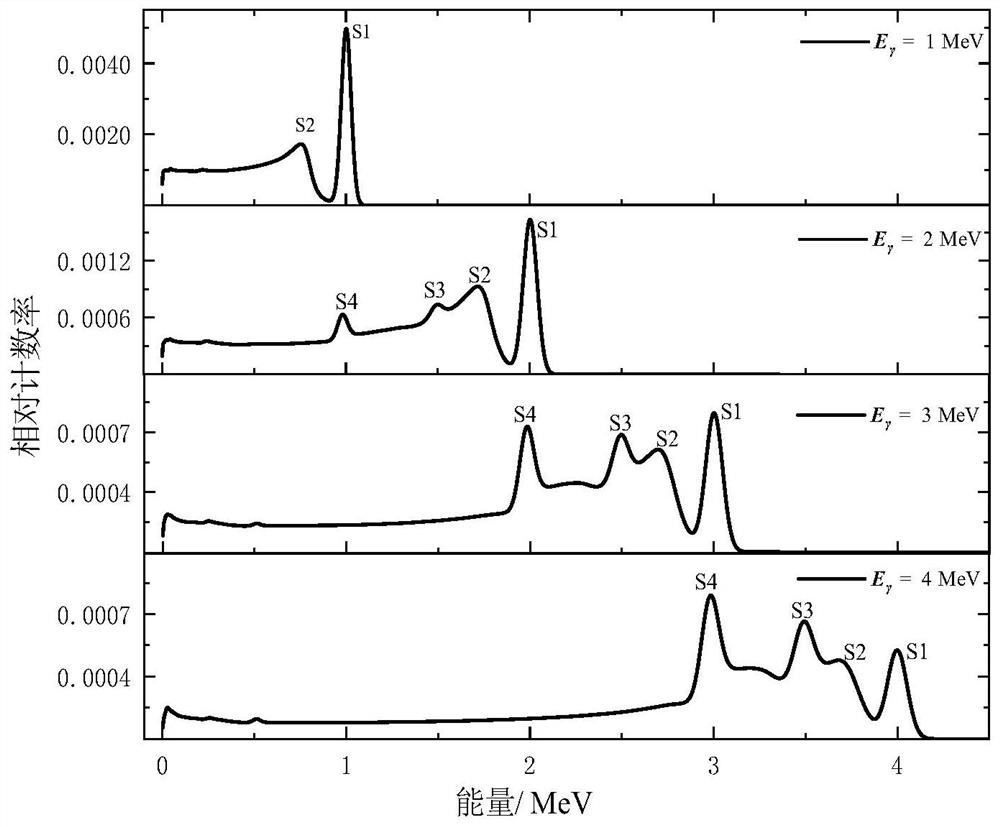

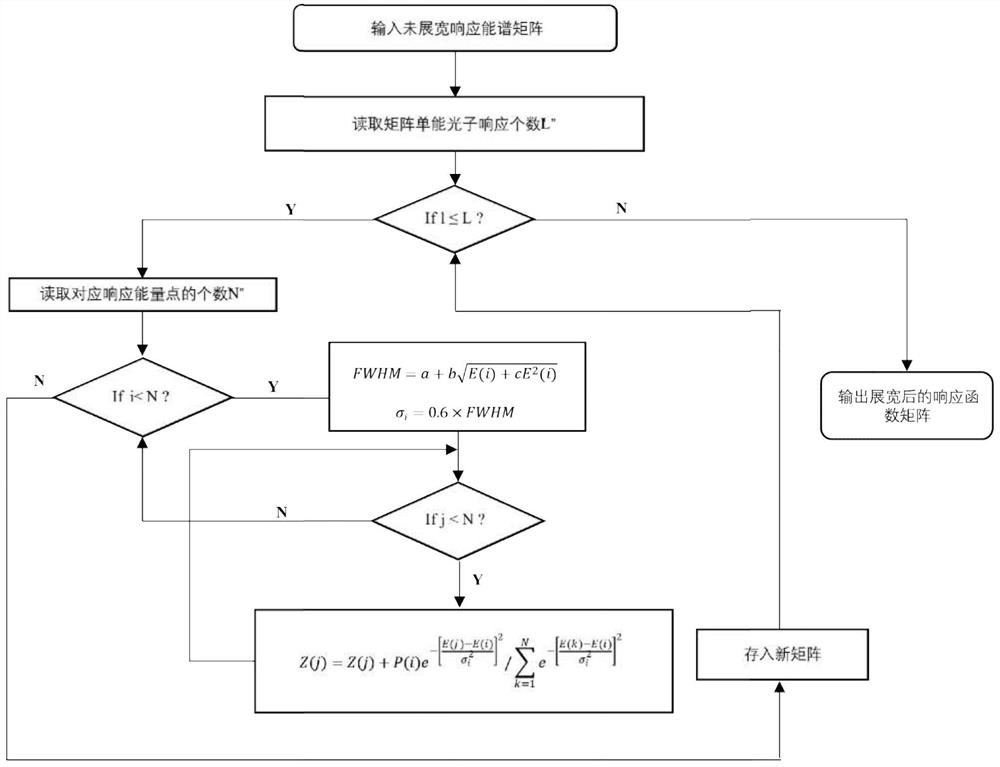

Gaussian broadening and spectrum unfolding method of gamma response function of detector

ActiveCN112906193ASmall fluctuationImprove accuracyX-ray spectral distribution measurementDesign optimisation/simulationMixed spectrumBatch processing

The invention discloses a Gaussian broadening and spectrum unfolding method for a gamma response function of a detector, which comprises the following steps of: firstly, performing Gaussian broadening on each energy point in a certain unbroadened energy spectrum by adopting Gaussian broadening of an analytical method according to a relationship between full width at half maximum and energy to obtain a response function under a specific energy resolution; secondly, broadening the unbroadened energy spectrums of the incident photons with different energies in sequence by using an MATLAB batch processing program to obtain a response matrix formed by response functions under different energies; and finally, solving the mixed gamma energy spectrum by using a weighted least square method in combination with the response matrix. According to the method, the response matrix broadened by the analytical method is reliable, after the change of the energy resolution of the mixed spectrum is simulated, the fluctuation of solving the mixed spectrum by the response matrix under the corresponding energy resolution is small, the accuracy is high, and the solving effect of the weighted least square method under the corresponding energy resolution is good. Gaussian broadening is carried out by adopting an analytical method, broadening parameters can be adjusted according to reality, and a more convenient mode is provided for constructing a response matrix under the corresponding energy resolution.

Owner:LANZHOU UNIVERSITY

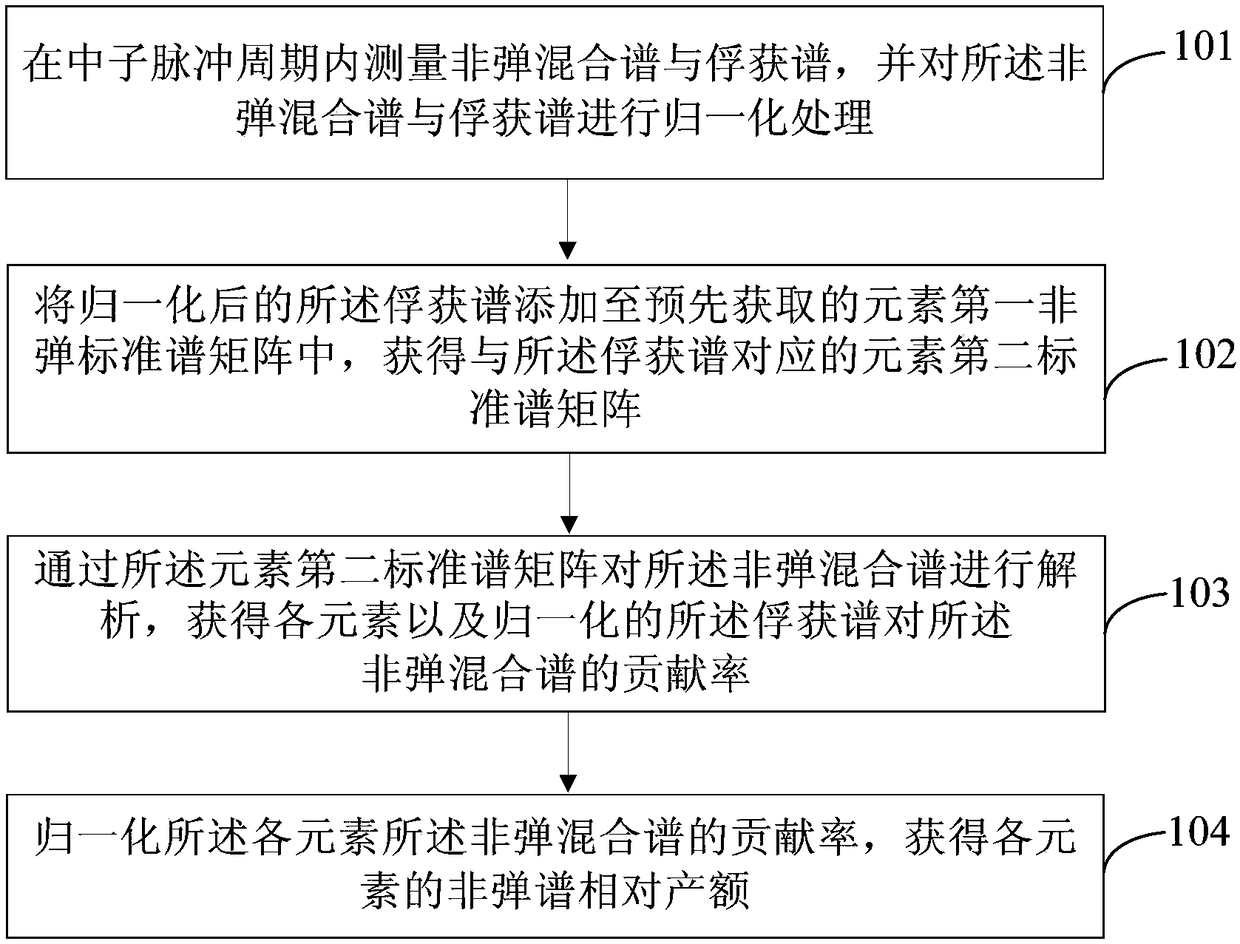

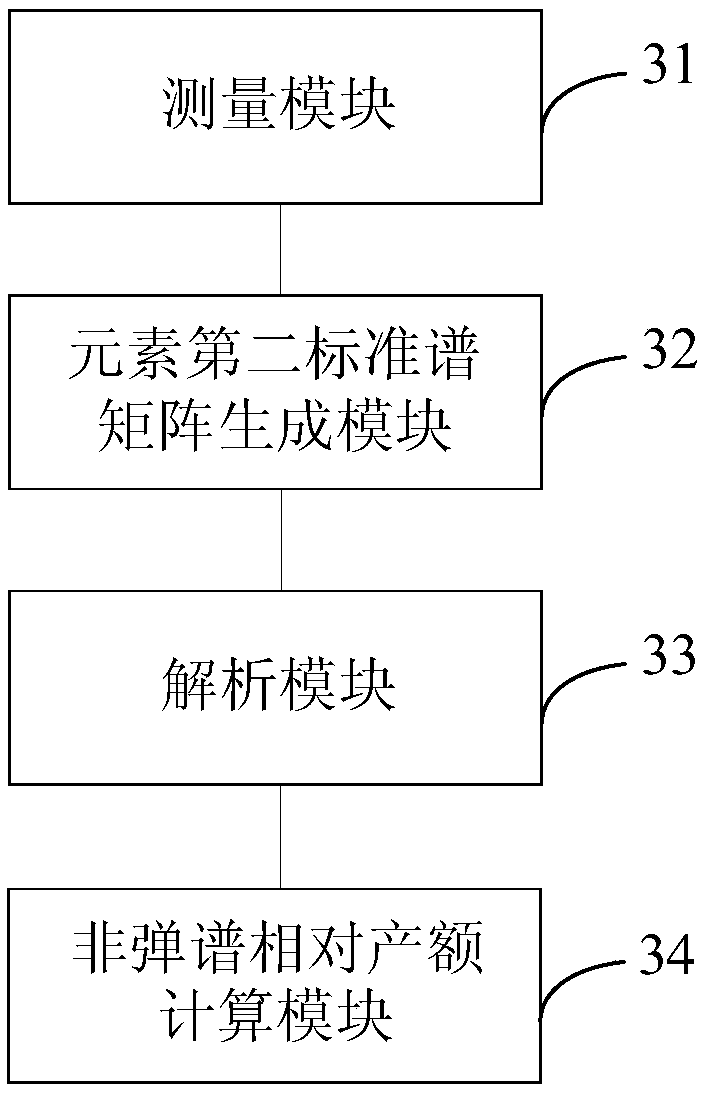

Inelastic scattering gamma-ray spectrometry analysis method and device

ActiveCN108535786AAvoid oilyAvoid accuracyNuclear radiation detectionInelastic scatteringMixed spectrum

The invention provides an inelastic scattering gamma-ray spectrometry analysis method and device. The method comprises the steps as follows: inelastic mixed spectrum and capture spectrum are measuredin a neutron pulse cycle and subjected to normalization processing; the normalized capture spectrum is added to an element first inelastic standard spectrum matrix obtained in advance, and an elementsecond standard spectrum matrix corresponding to the capture spectrum is obtained; the inelastic mixed spectrum is analyzed through the element second standard spectrum matrix, and contribution ratesof elements and the normalized capture spectrum for the inelastic mixed spectrum are obtained; the contribution rates of all the elements for the inelastic mixed spectrum are normalized, and inelasticspectrum relative yields of all the elements are obtained. Pure inelastic spectrum is not required to be obtained firstly during measurement of inelastic spectrum relative yields of all the elements,so that the defect of inaccurate underground stratum oil saturation due to defects of a fixed pure spectrum coefficient method which is mainly adopted at present can be overcome.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

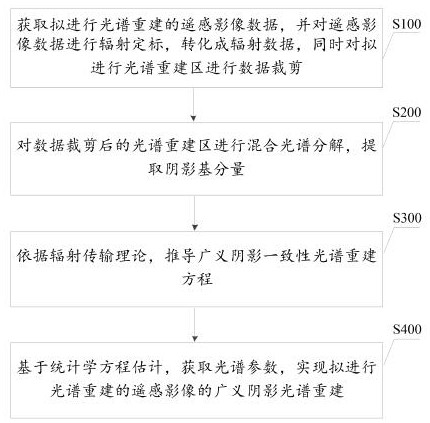

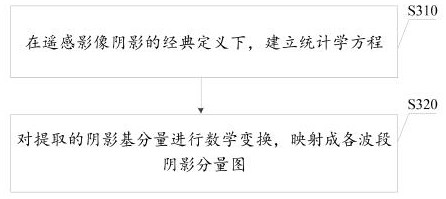

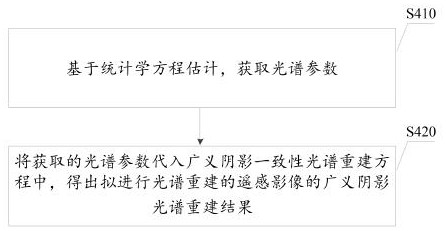

Remote sensing image generalized shadow spectrum reconstruction method and system based on statistics

ActiveCN111738916ANatural color transitionEliminate miscorrectionsImage enhancementImage analysisMixed spectrumComputer vision

The invention discloses a remote sensing image generalized shadow spectrum reconstruction method and system based on statistics, and the method comprises the steps: obtaining remote sensing image datato be subjected to spectrum reconstruction, carrying out the radiometric calibration of the remote sensing image data, converting the remote sensing image data into radiation data, and carrying out the data cutting of a to-be-subjected spectrum reconstruction region; performing mixed spectrum decomposition on the spectrum reconstruction area after data cutting, and extracting a shadow base component; deducing a generalized shadow consistency spectrum reconstruction equation according to a radiation transmission theory; and based on statistical equation estimation, obtaining spectral parameters, and realizing generalized shadow spectral reconstruction of the remote sensing image to be subjected to spectral reconstruction. According to the method, the classical definition of traditional remote sensing image shadows is broken through, a generalized shadow consistency spectrum reconstruction equation is derived, the reconstruction result is natural in color transition, the texture is moreprominent, no edge effect exists, and the effect is very remarkable; and the fidelity of the information recorded by the image data is kept to the greatest extent.

Owner:湖南省有色地质勘查研究院 +1

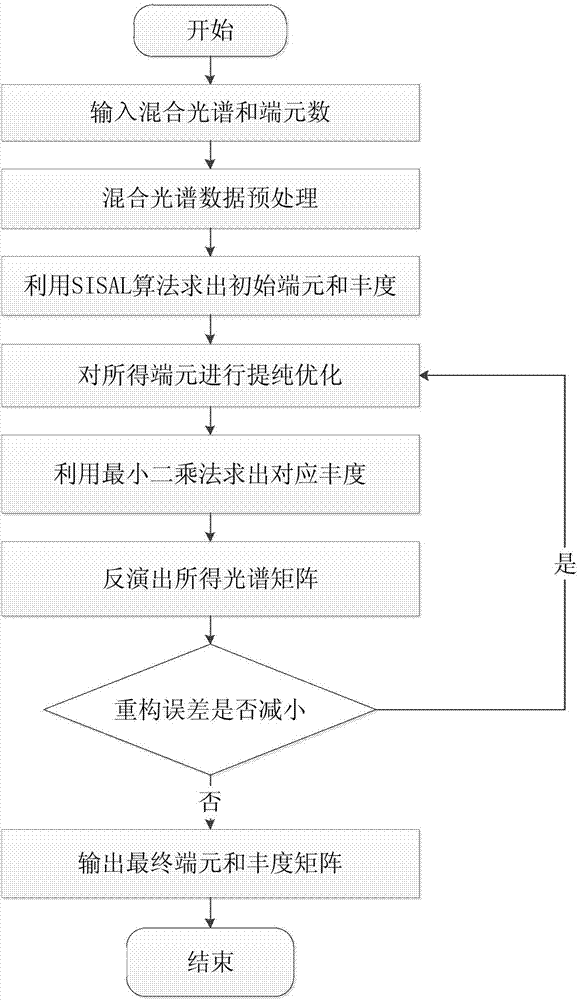

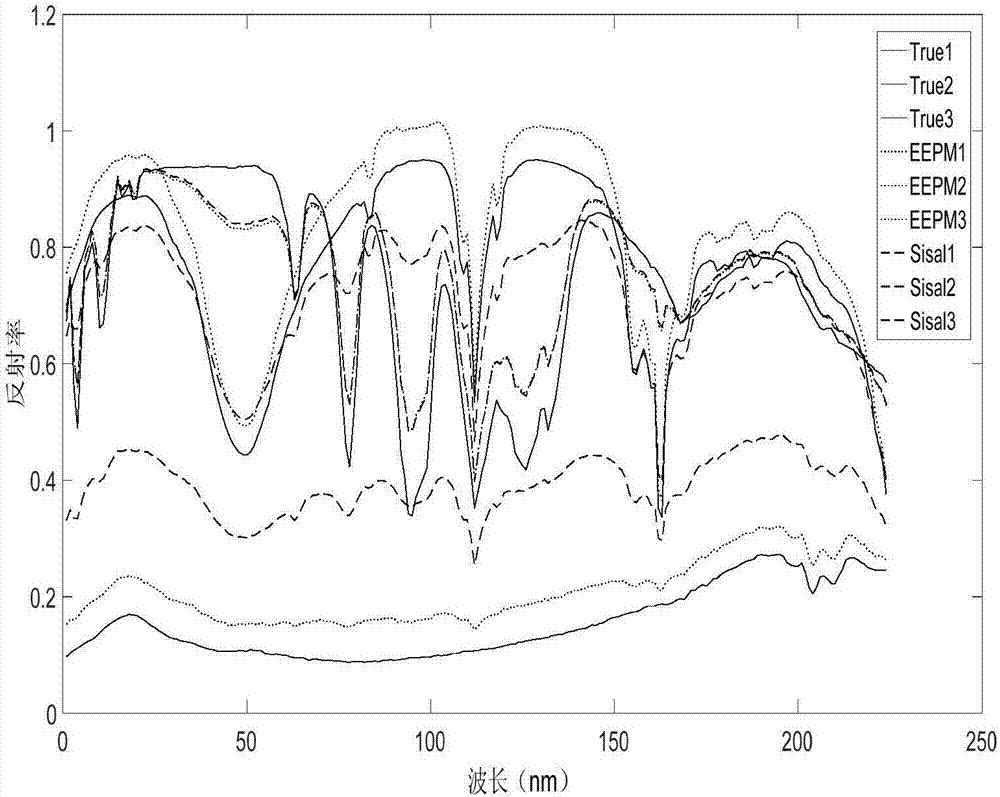

Purification and optimization-based space target spectrum de-mixing method

ActiveCN107977943AChoose accuratelyApproximately accurateImage enhancementImage analysisMixed spectrumPurification methods

The invention discloses a purification and optimization-based space target spectrum de-mixing method. The method comprises the following steps of: firstly extracting an end member of an original sparse spectrum by adoption of variable division augmented Lagrange algorithm through a purification method, wherein the purification method is capable of effectively selecting an initial end member of a mixed spectrum so as to decrease a calculated amount; carrying out iterative purification and optimization on the initially extracted end member by utilizing an end member purification and optimizationmethod, wherein the optimized end member approaches a real end member step by step; and finally comparing the purified and optimized end member and an abundance with the original spectrum, and continuously carrying out purification until a reconstruction error of the purified end member is greater than a minimum value of a previous error, wherein the obtain end member and the abundance are optimal solutions. The method has the advantages of being strong in robustness and high in speed, and is capable of carrying out correct solution under the condition of low information amount.

Owner:BEIHANG UNIV

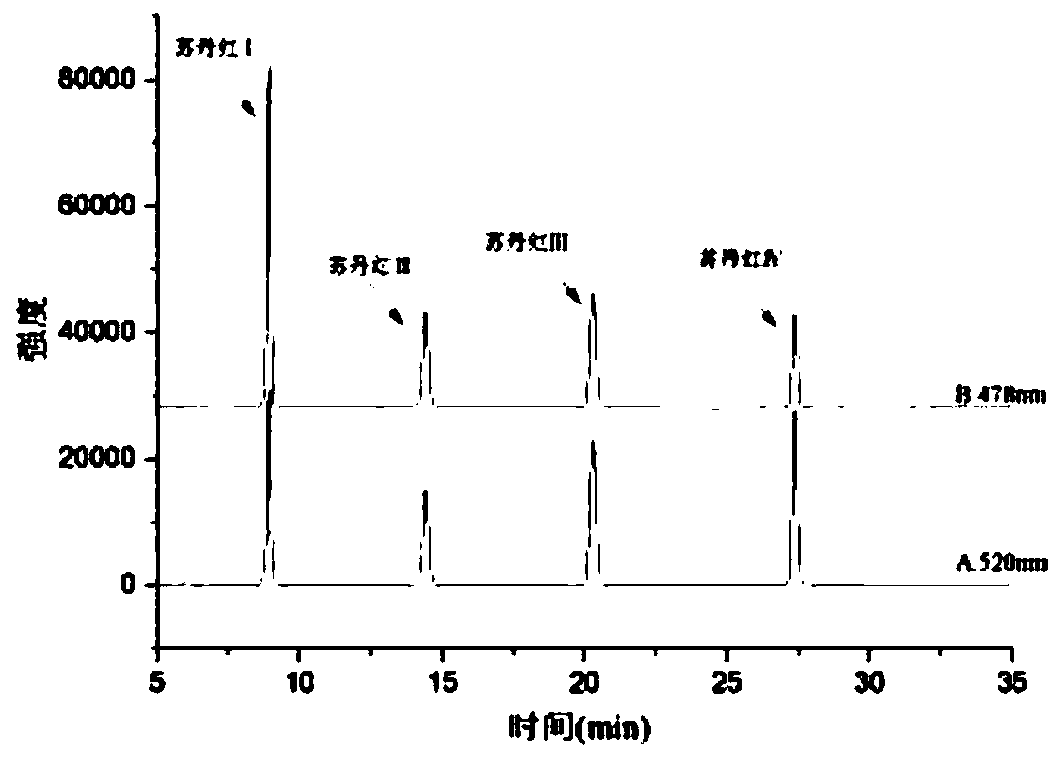

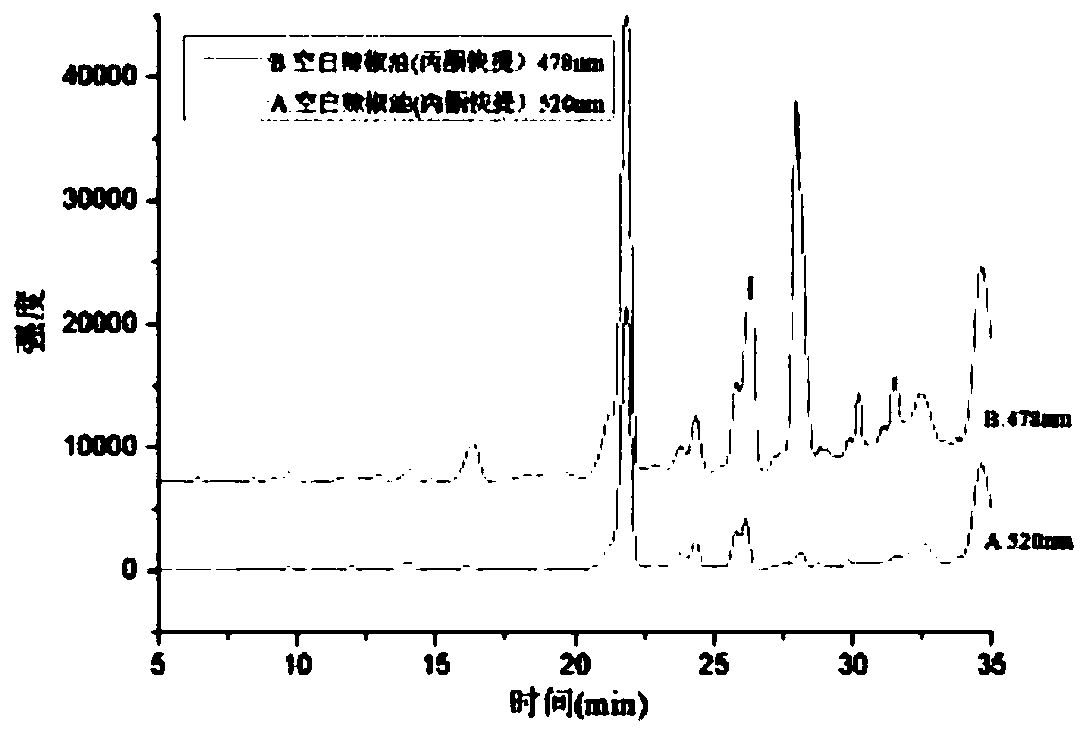

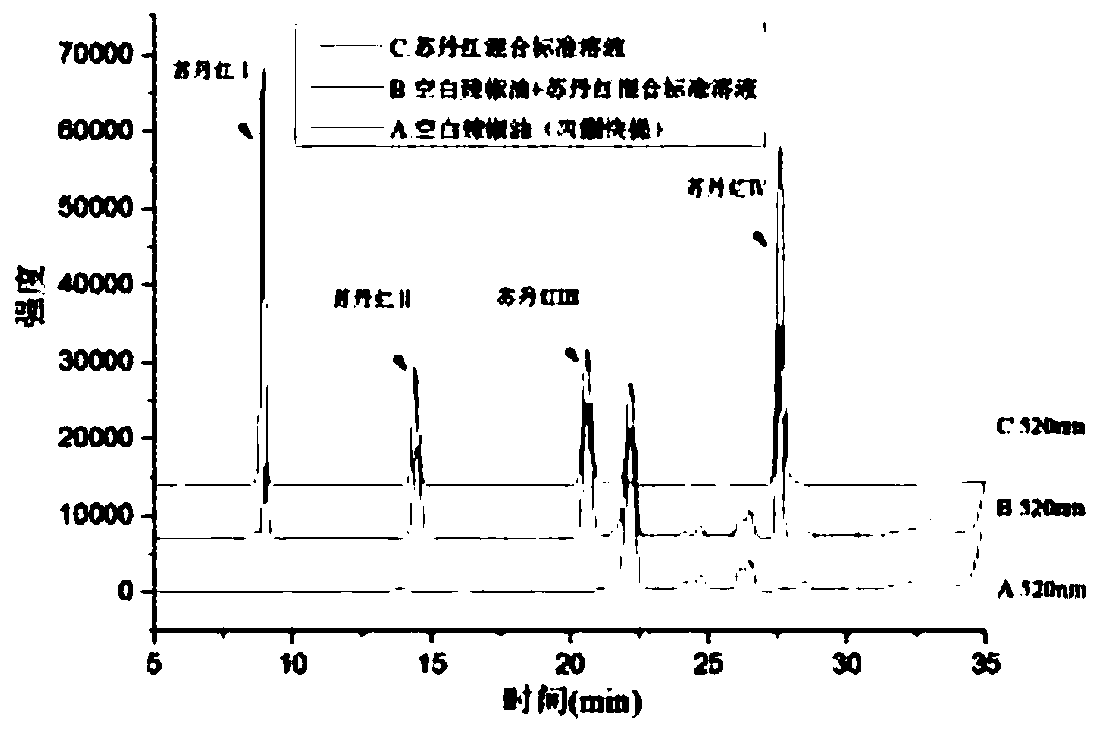

Method for rapidly detecting Sudan red in pepper products

InactiveCN109765326AExperiment operation is simpleShorten the timeComponent separationFiberSpectral database

The invention relates to a Sudan red detection method and in particular to a method for rapidly detecting Sudan red in pepper products. According to the method, a pepper product is rapidly extracted by using acetone and acetonitrile so as to obtain extracting solution S, a liquid chromatography-ultraviolet visible fiber optic spectrometer is applied to analyzing the extracting solution S, and dataprocessing is carried out to obtain a background spectral database N which does not contain Sudan red; ultraviolet-visible spectral databases V of a series of Sudan red standard products with concentrations; and finally, a vector-subspace included angle criterion method is used for analyzing Sudan red in the pepper product: the to-be-detected product is rapidly extracted to obtain extracting solution C and ultraviolet-visible spectral data of the extracting solution C is acquired to calculate the content of Sudan red in the to-be-detected pepper product. The method is rapid and good in effectand is capable of respectively carrying out qualitative recognition and quantitative analysis on pure spectrums of Sudan red I, II, III and IV in mixed spectrums of marked samples.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

Deconvolution of Mixed Spectra

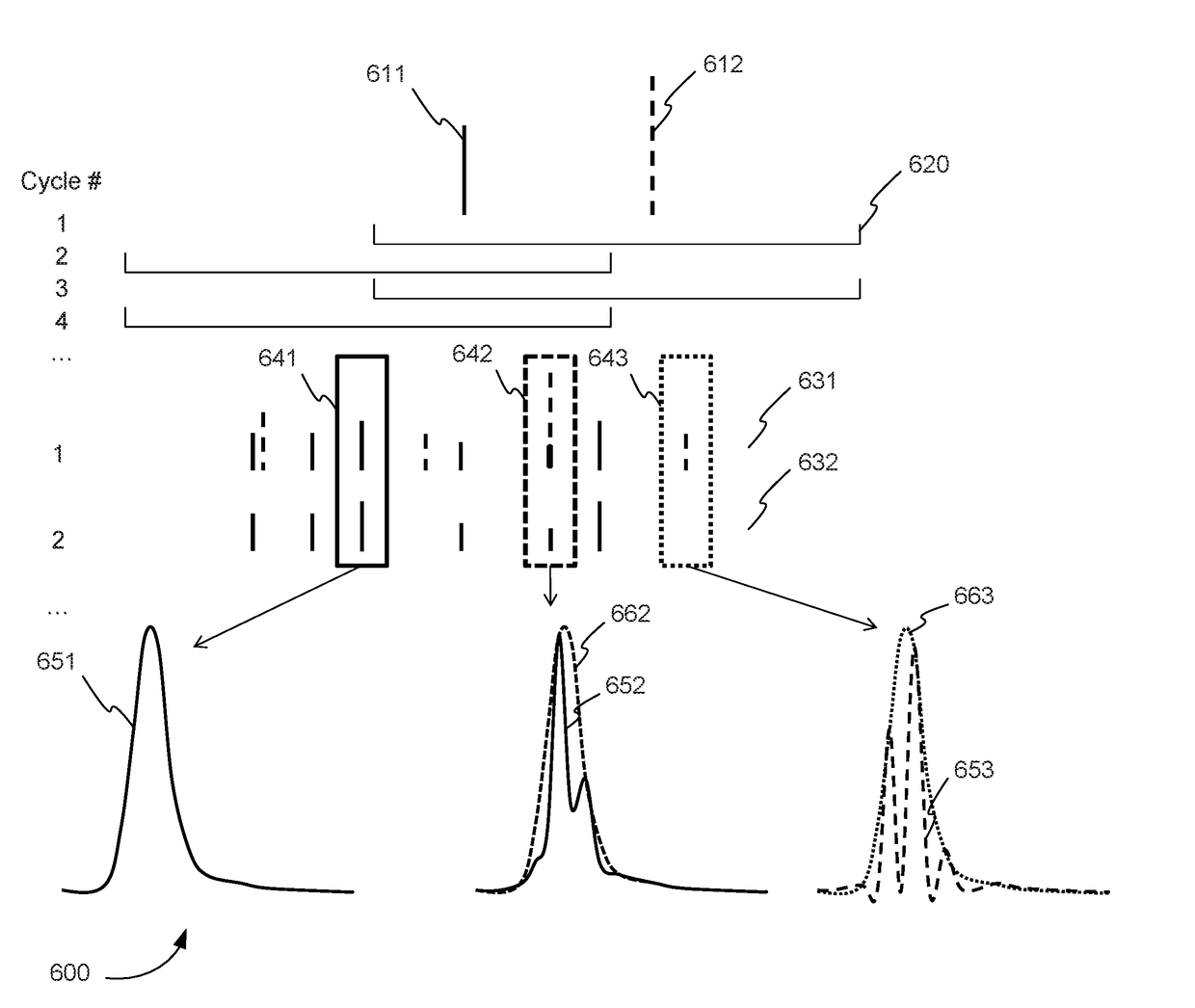

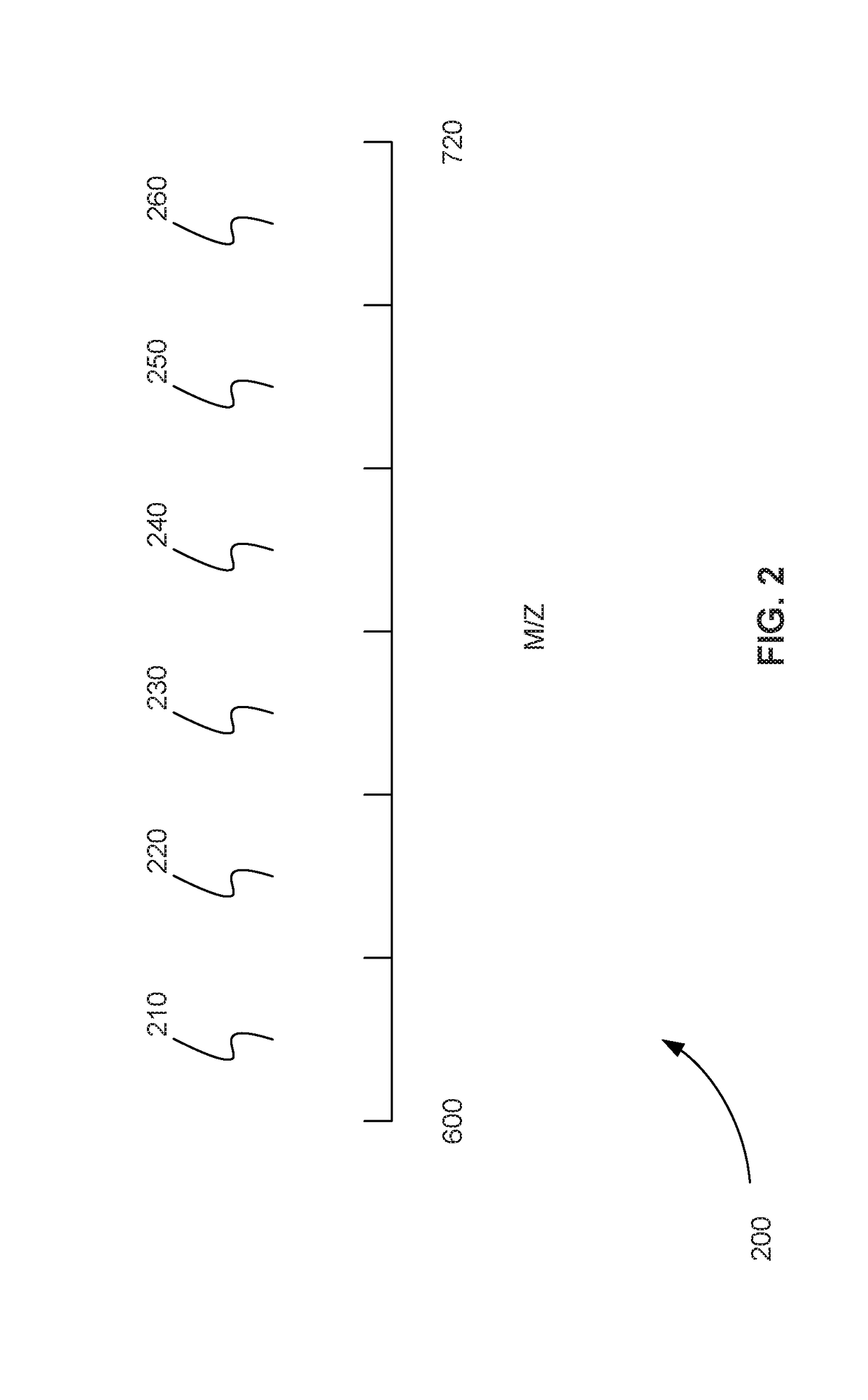

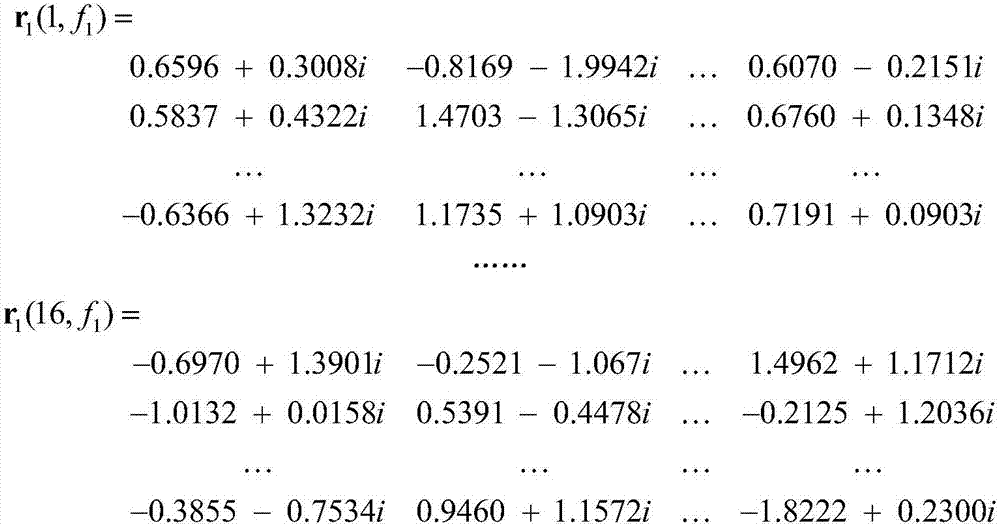

ActiveUS20180240658A1Good reproducibilityImprove comprehensivenessSamples introduction/extractionParticle spectrometer methodsIon beamInitial window

An m / z range of an ion beam is divided into two or more precursor ion mass selection windows. A pattern of two or more different window m / z ranges to be used during two or more successive cycles for at least one precursor ion mass selection window is determined. The pattern includes an initial window m / z range and one or more successively different window m / z ranges. Each of the one or more successively different window m / z ranges includes at least a portion of the initial window m / z range. A tandem mass spectrometer is instructed to select and fragment the two or more precursor ion mass selection windows during each cycle of a plurality of cycles and to repeatedly use the pattern for each group of two or more successive cycles of the plurality of cycles for the selection and fragmentation of the at least one precursor ion mass selection window.

Owner:DH TECH DEVMENT PTE

Under-sampled multi-array cooperative frequency-measuring and direct-positioning method

The invention belongs to the technical field of electronic information, and in particular relates to a method for measuring the frequency of a target signal from a mixed spectrum and directly positioning the target signal by utilizing multiple under-sampled array receiving signal vectors. An under-sampled multi-array cooperative frequency-measuring and direct-positioning method comprises the steps of: initializing at first, then, according to the L frame of each array and continuous N sampling receiving signal vectors of each frame, determining a sample autocorrelation matrix of the array receiving signal vectors, furthermore, determining the signal subspace of the array, then, determining the numerical value of an empty spectrum corresponding to the position grid point and each frequency grid point in a position grid point set and a frequency grid point set by utilizing the signal subspaces of all the arrays, and finally, determining the position grid point and the frequency grind point corresponding to the maximum value of a spatial spectrum as the position and the frequency of the target signal. By means of the under-sampled multi-array cooperative frequency-measuring and direct-positioning method disclosed by the invention, the multiple array receiving signal vectors are utilized; under the uniform sampling condition that the sampling rate is lower than the Nyquist sampling rate, the frequency of the target signal can be rapidly recovered from the mixed spectrum; and simultaneously, the target signal can be directly positioned.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

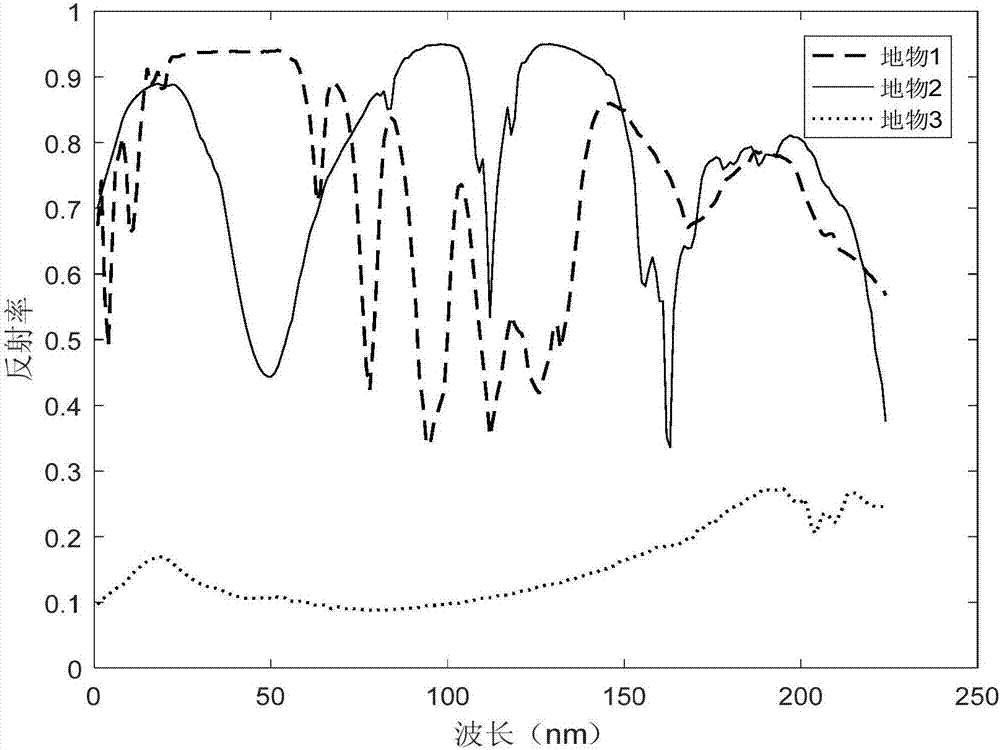

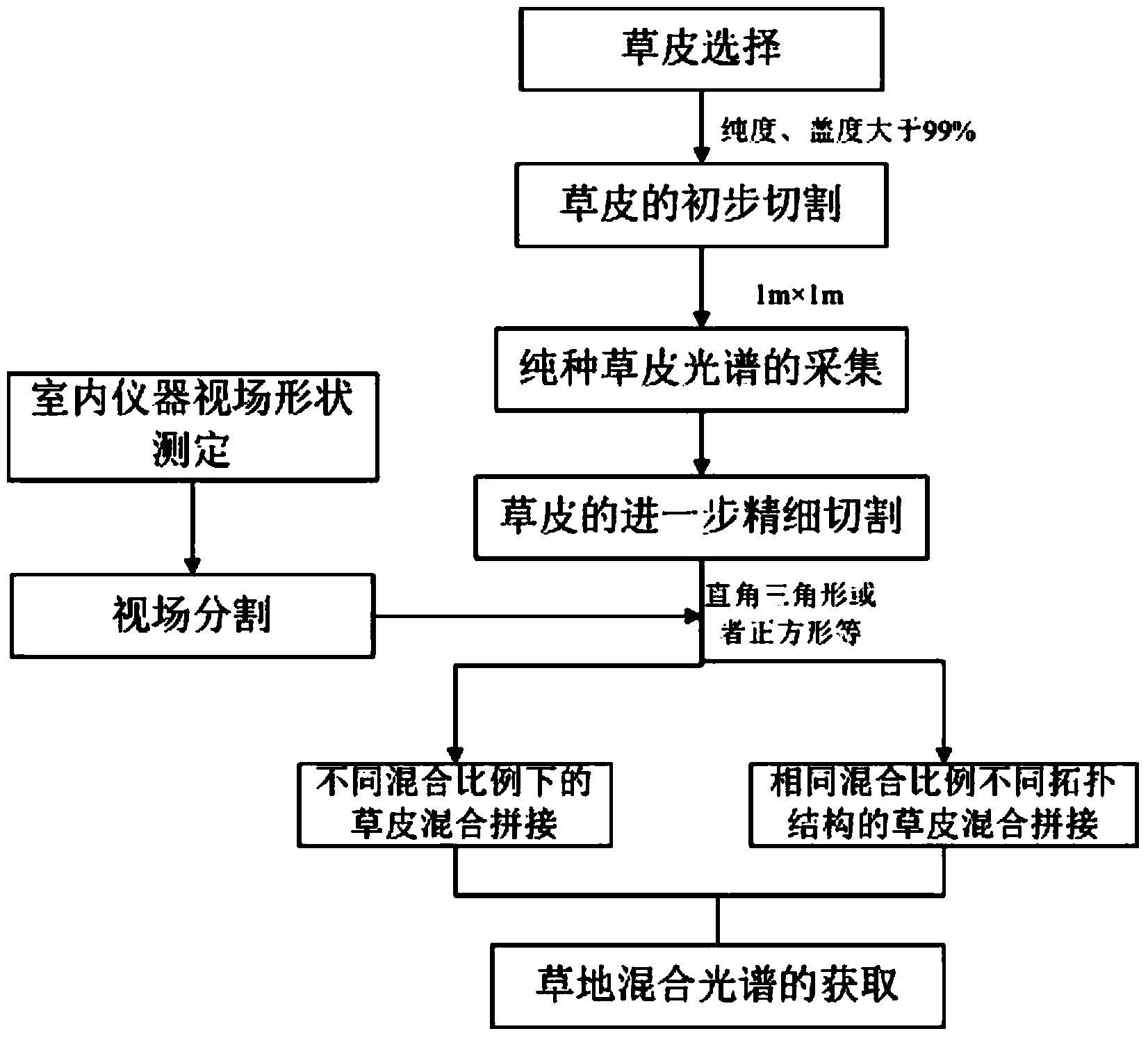

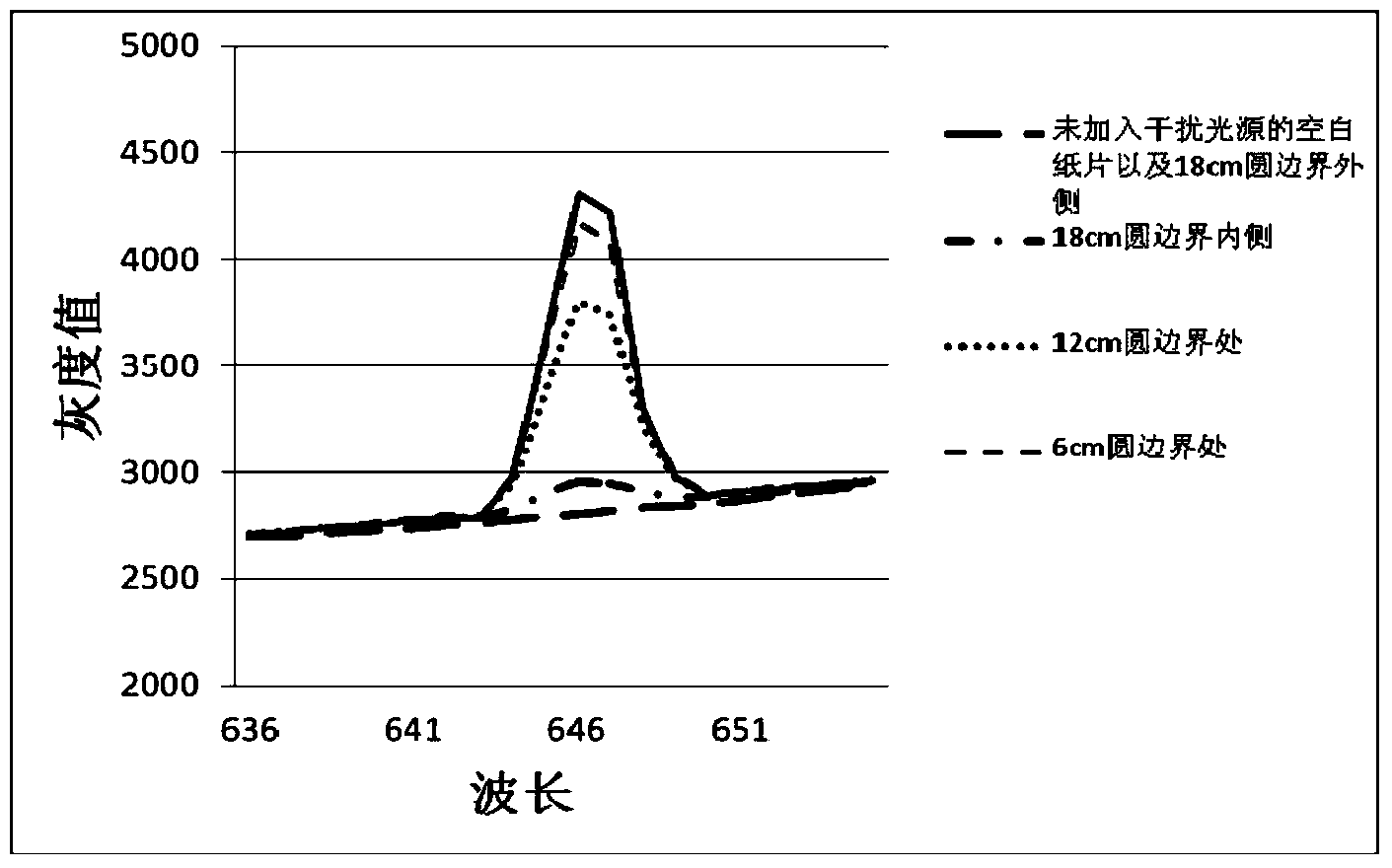

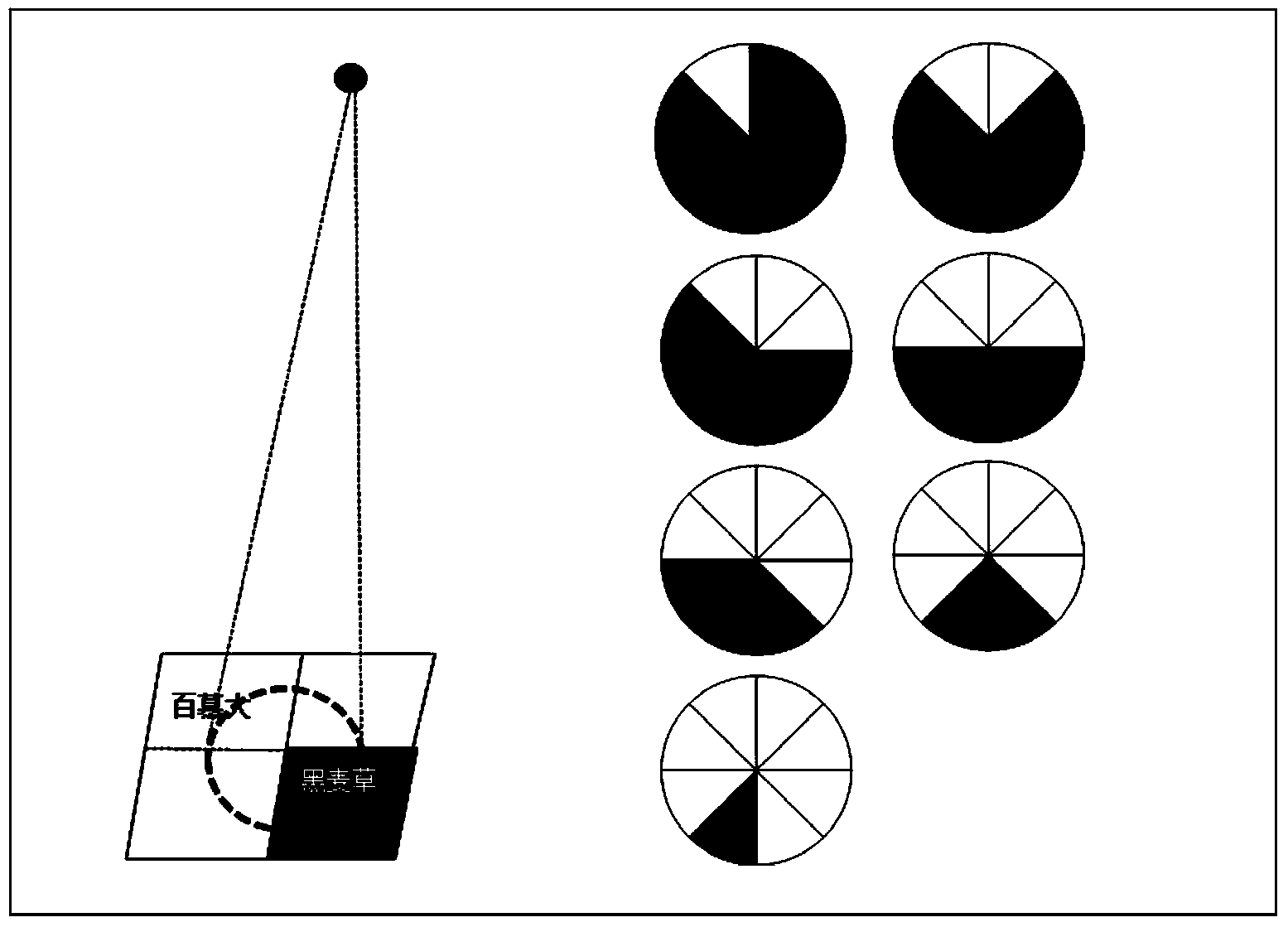

Controllable-abundance grassland mixed spectrum acquisition experimental method

ActiveCN103674247AEasy accessAccurate acquisitionSpectrum investigationColor/spectral properties measurementsMixed spectrumExperimental methods

The invention discloses a controllable-abundance grassland mixed spectrum acquisition experimental method. The method includes: measuring the shape of a view field of a spectrograph detector by a 'laser beam interference method'; manually splicing turfs into a grassland mixed pixel in the domain range of view field; simulating natural mixed grasslands different in type, mixing ratio and topological location distribution so as to acquire end element spectrum and mixed spectrum data. The method is applicable to the construction and precision verification of a grassland remote-sensing mixed pixel unmixing model. The method has the advantages that the limitation that the end element spectrum is hard to acquire and unmixing abundances are difficult to verify during unmixing study of natural grasslands is overcome, abundances of the end elements in the grassland mixed spectrum are controllable, mass mixed spectral data with known abundances can be obtained, unmixing accuracy of various mixed spectrum models can be accurately verified, and the method is reliable and has practical value.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com