Weld width prediction method before molten pool forming based on mixed spectrum vision

A technology of mixing spectrum and weld width, which is applied in image analysis, image enhancement, instruments, etc., can solve problems such as poor imaging quality, achieve good results, improve accuracy, and reduce device complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following is a detailed description of the embodiments in conjunction with the accompanying drawings, but the provided embodiments are not intended to limit the scope of the present invention, and the description of the structure and operation is not intended to limit the order of execution. Any recombination of components Structures, resulting devices with equivalent functions are all within the scope of the present invention.

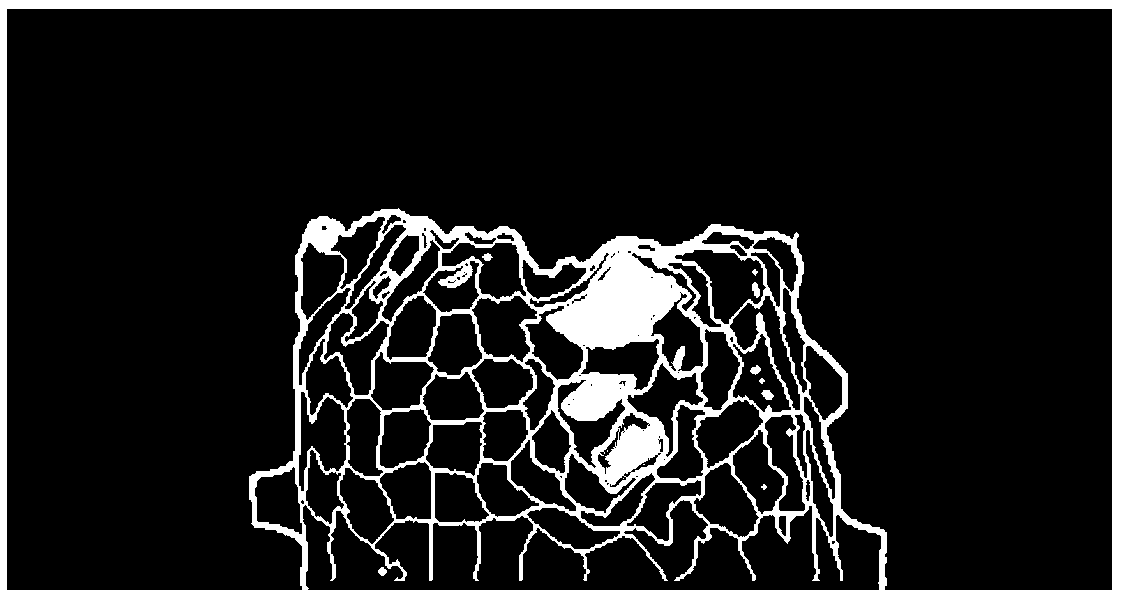

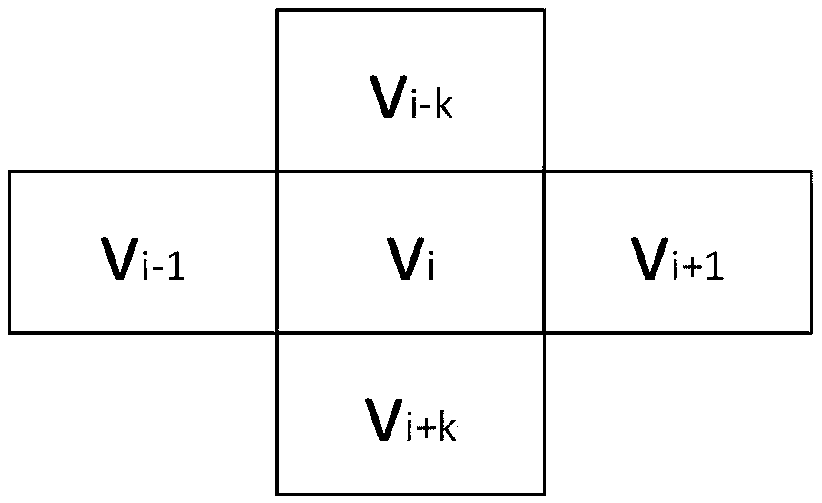

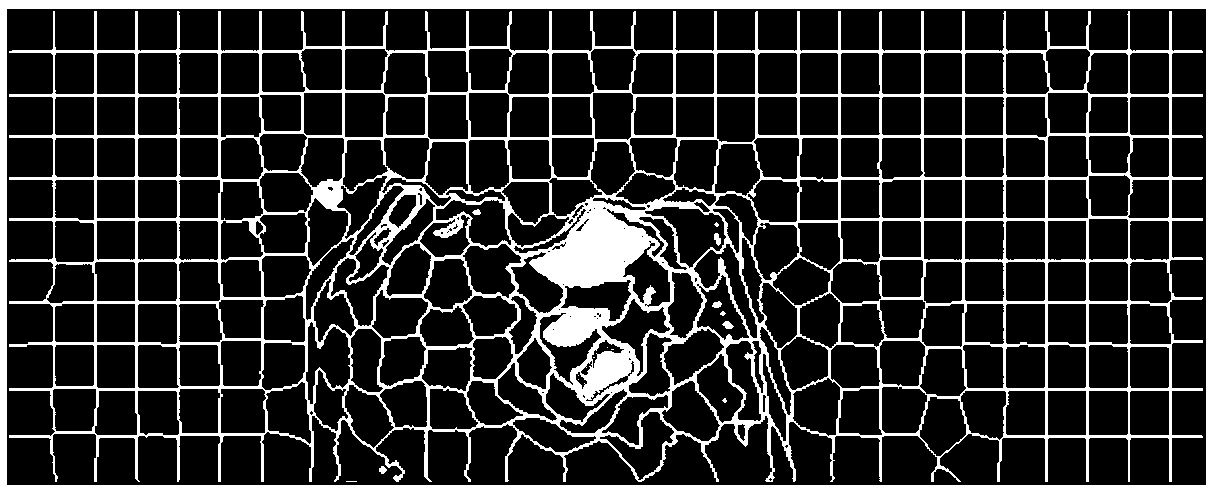

[0058] The method for extracting the outline of the melting pool based on gradient and grayscale superpixel merging optimization of the present invention obtains the outline of the melting pool image through this method. The online method for predicting the width of the weld before forming based on the molten pool profile includes the following steps:

[0059] Step 1. A passive molten pool vision sensing system based on mixed-spectrum dual-band imaging was established. The two optical paths were respectively filtered with an 850nm high-pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com