Light mixing film for mixing light from light emitting diode backlight source and light emitting diode backlight source

A technology of light-emitting diodes and backlight sources, which is applied to semiconductor devices, light sources, point light sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

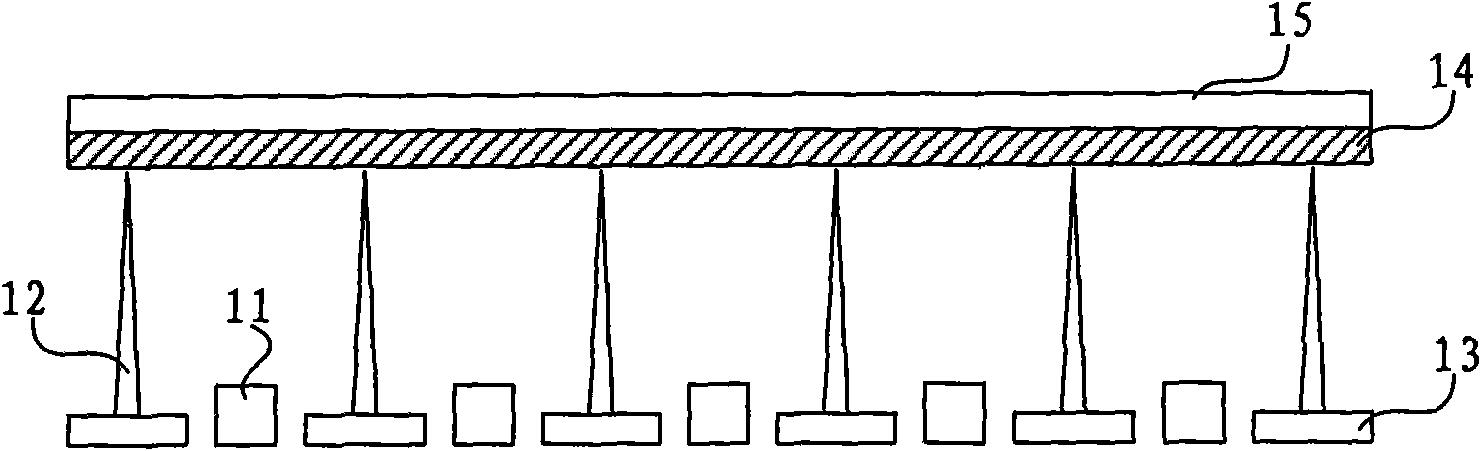

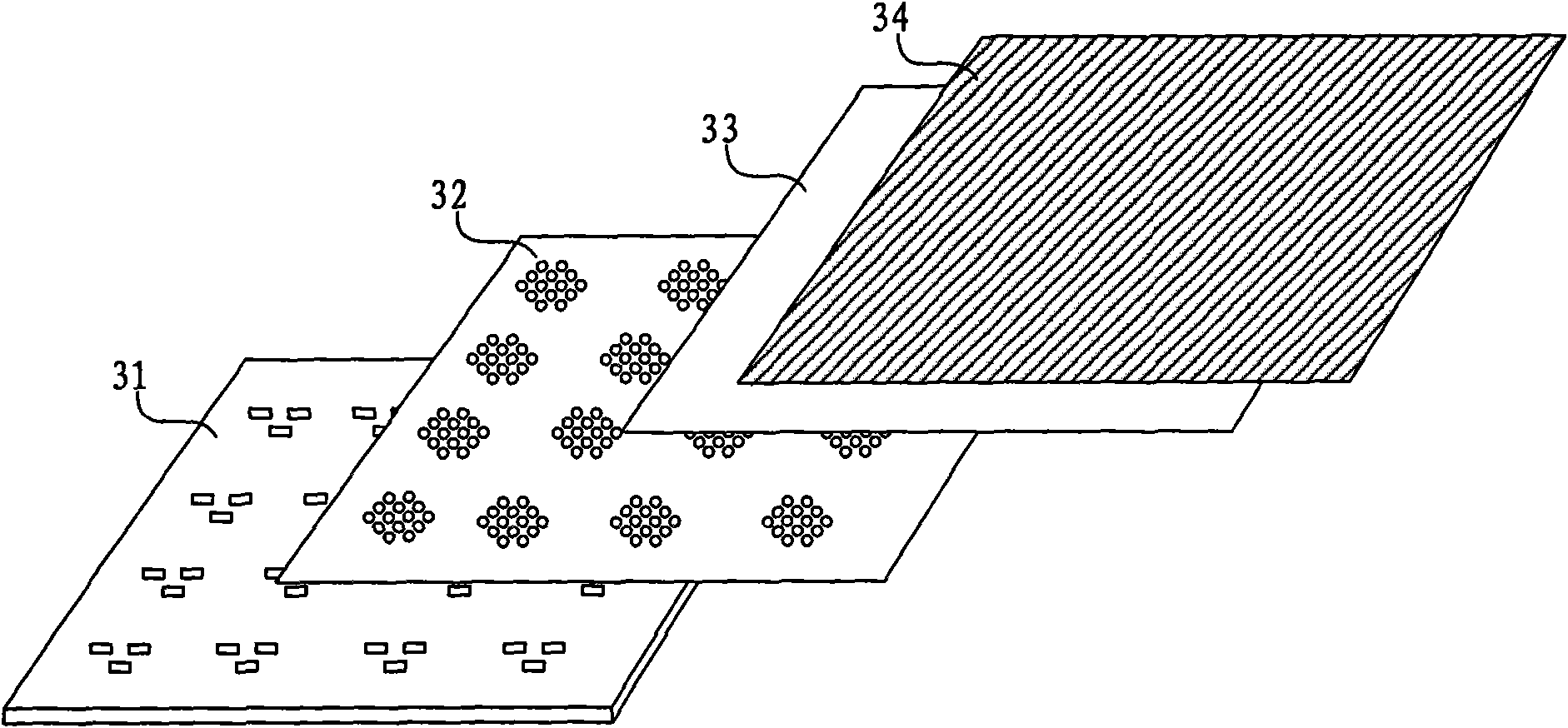

[0015] In order to achieve uniform light mixing without increasing the light mixing distance of the direct LED backlight and the number of LEDs, the embodiment of the present invention adds a layer of light mixing film above the LED lamp group, and the light mixing film corresponds to each A set of dots is set directly above a group of LED lights, which can partially transmit the strong light emitted by the LEDs and partially reflect it back to the bottom reflective film, thus reducing the generation of bright spots and mixing the light evenly within a shorter distance .

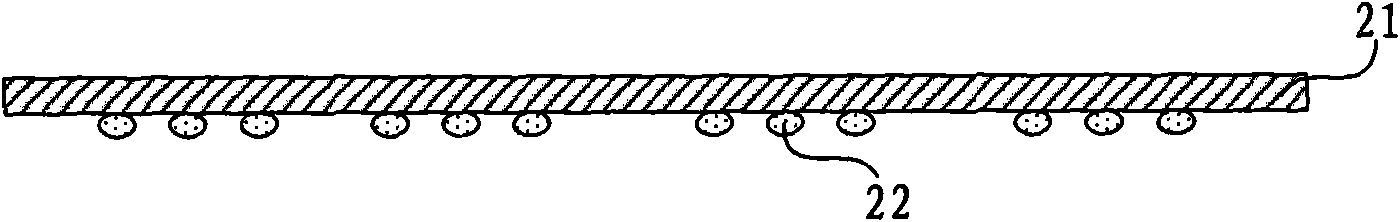

[0016] figure 2 It is a structural schematic diagram of an embodiment of the light mixing film used for light mixing of light-emitting diode backlight sources in the present invention. The light mixing film includes a substrate 21 and dots 22 arranged on the substrate 21 . The substrate 21 can be made of a light-transmitting material with high transmittance such as polymethyl methacrylate (PMMA), polycarb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com