Directly-down backlight module unit

A backlight module and direct-type technology, which is applied in the field of direct-type backlight modules, can solve problems affecting color purity, LED frequency drift, and shorten working life, and achieve the effects of suppressing spectrum drift, expanding heat dissipation area, and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

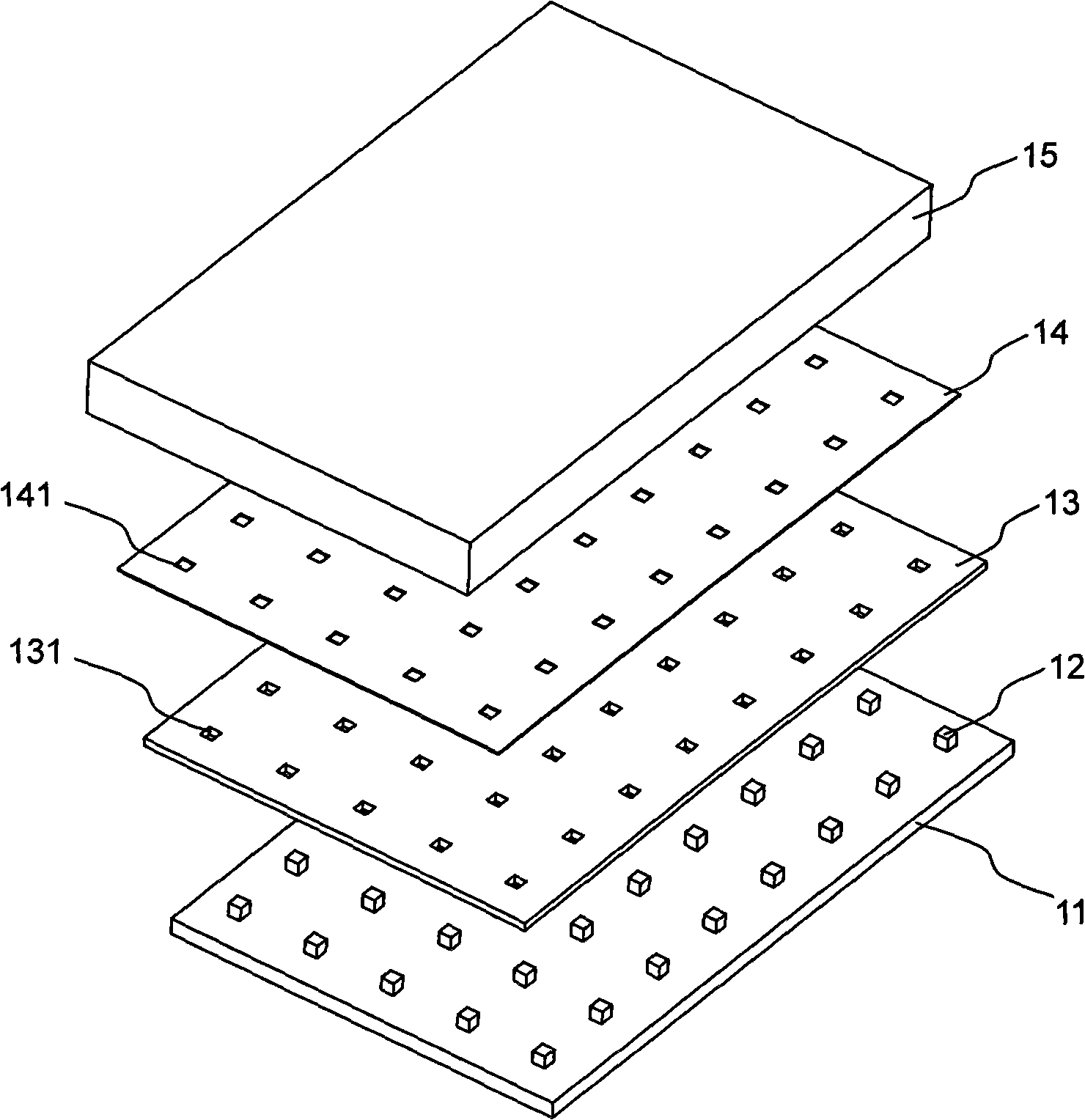

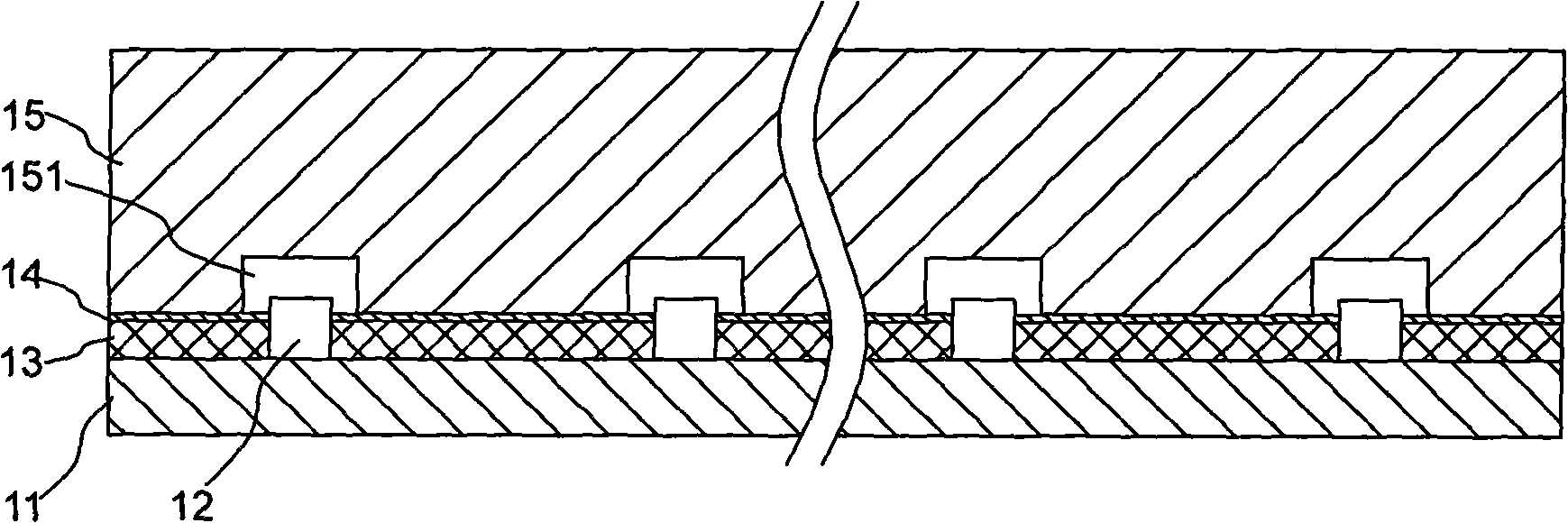

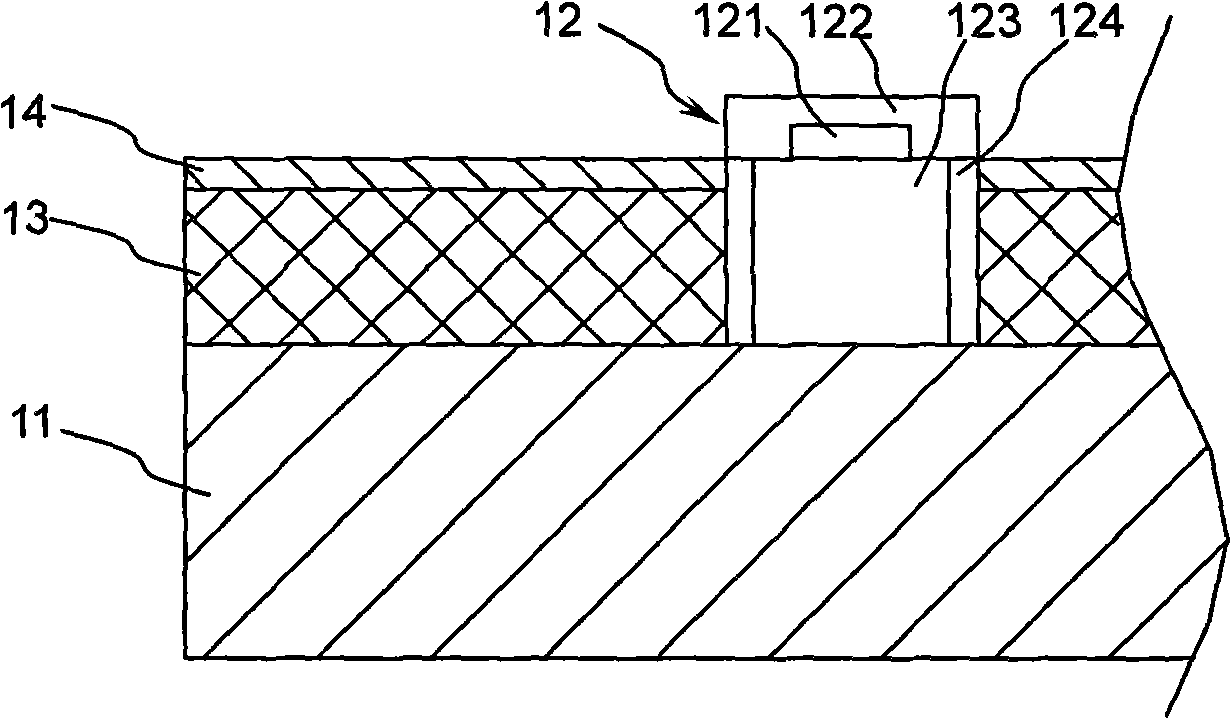

[0020] figure 1 It is an exploded schematic view of the direct type backlight module according to the embodiment of the present invention; figure 2 yes figure 1 A cross-sectional view of a direct-lit backlight module. As shown in the figure, the direct-type backlight module of the present invention includes a backplane 11; several LED light sources 12 are pasted on the backplane 11 by adhesive or solder according to certain arrangement requirements; a printed circuit board (PCB) 13. Place it on the back plate 11, and electrically connect the LED light source 12. There is an opening 131 hollowed out at the corresponding position of the LED light source 12, so that the LED light source 12 can pass through; the reflector 14 is placed on the printed circuit board 13 On the top, there is an opening 141 hollowed out at the corresponding position of the LED lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com