Direct type backlight source

A backlight and direct-type technology, which is applied in the field of direct-type backlights, can solve the problems of large thickness of direct-type backlights, and achieve the effects of reducing light mixing distance, reducing thickness, and increasing operating distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

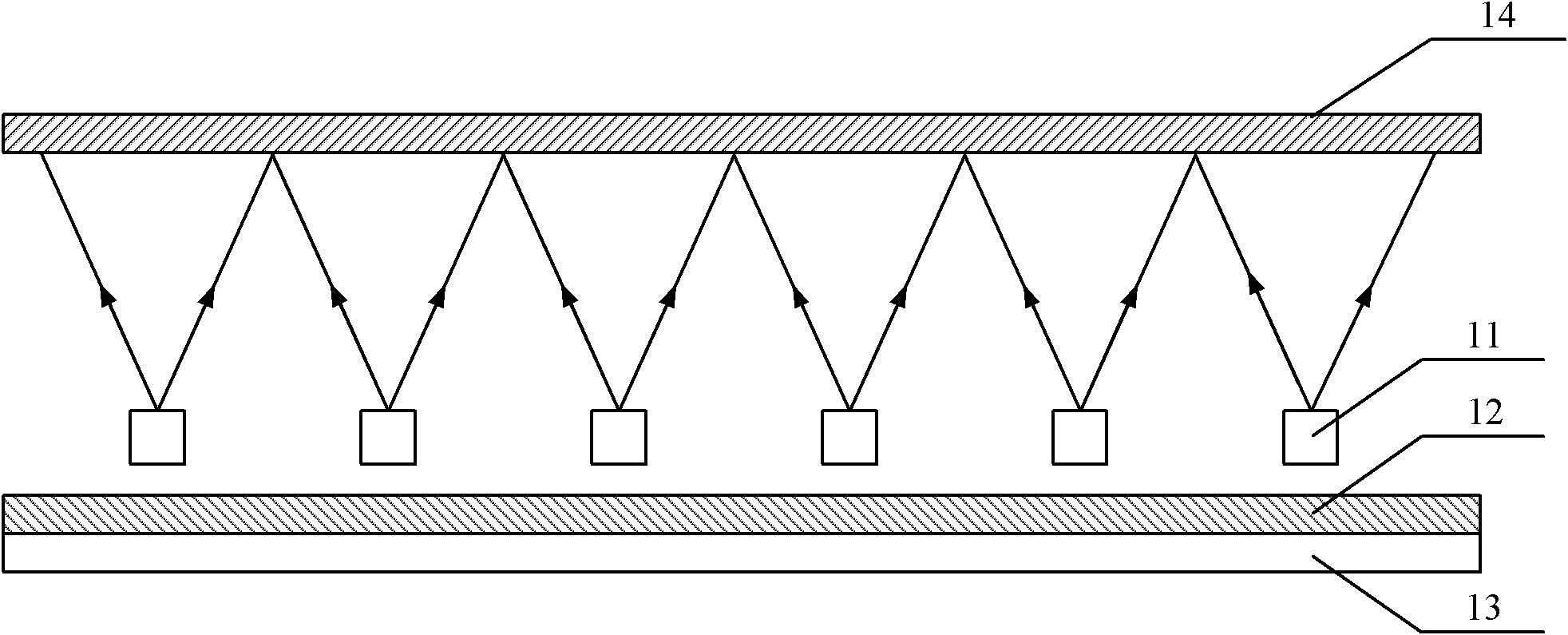

[0029] Embodiment 1 of the present invention provides a direct-lit backlight. The direct-lit backlight is provided with a semi-transparent and semi-reflective layer with a reflectivity greater than 0 and less than 1 between the diffuser and the illuminant. Part of the light emitted by the illuminant Multiple reflections are performed in the cavity formed by the transflective layer and the reflector to fully mix, which is equivalent to increasing the distance between the light diffuser and the illuminant, thereby reducing the thickness of the direct-type backlight. In turn, the thickness of the entire LCD is reduced.

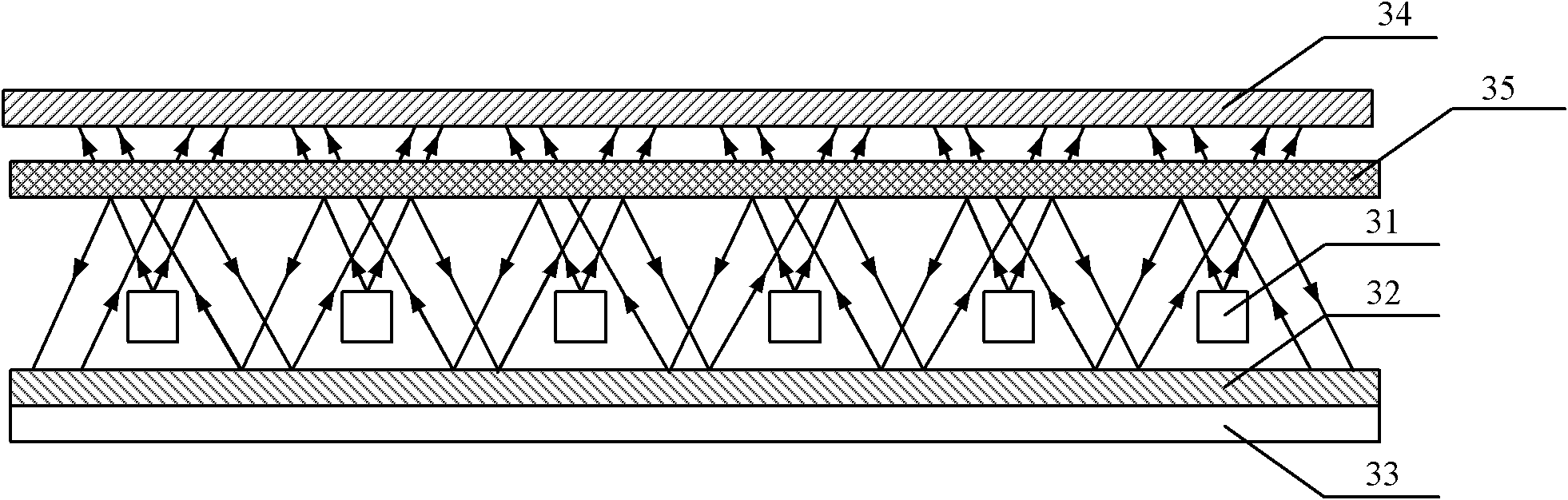

[0030] Such as image 3 As shown, it is a schematic diagram of the cross-sectional structure of the direct-lit backlight proposed in Embodiment 1 of the present invention, which includes several luminous bodies 31 arranged in parallel, a reflective sheet 32 located below the luminous body 31 , and a back plate 33 located below the reflective sheet 32 , the dif...

Embodiment 2

[0048] Such as Figure 13 As shown, it is a schematic diagram of the cross-sectional structure of the direct-lit backlight proposed in Embodiment 2 of the present invention, including several luminous bodies 131 arranged in parallel, a reflective sheet 132 located below the luminous body 131, and a back plate 133 located below the reflective sheet 132 1. The diffusion plate 134 located above the illuminant 131 also includes a surface coating 135 coated on the lower surface of the diffusion plate 134, the surface coating 135 is partially coated on the lower surface of the diffusion plate 134, and the surface coating 135 includes Several coating microstructures in intervals, the reflectivity of the coating microstructures is 1.

[0049] Part of the light emitted by the illuminant 131 reaches the diffuser plate 134, and is output after being diffused by the diffuser plate 134. Then it reaches the diffuser plate 134 or the coating microstructure, so that part of the light emitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com