Polyphenyl plate, polyphenyl particle plastered composite thermal-insulating wall and construction process

A technology of polystyrene particles and composite thermal insulation, which is applied in the direction of thermal insulation and building components, can solve the problems of failing to meet the design requirements of building energy-saving thermal insulation, the decline of wall thermal insulation effect, and complicated construction, so as to improve the wall thermal insulation effect and construction Simple, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

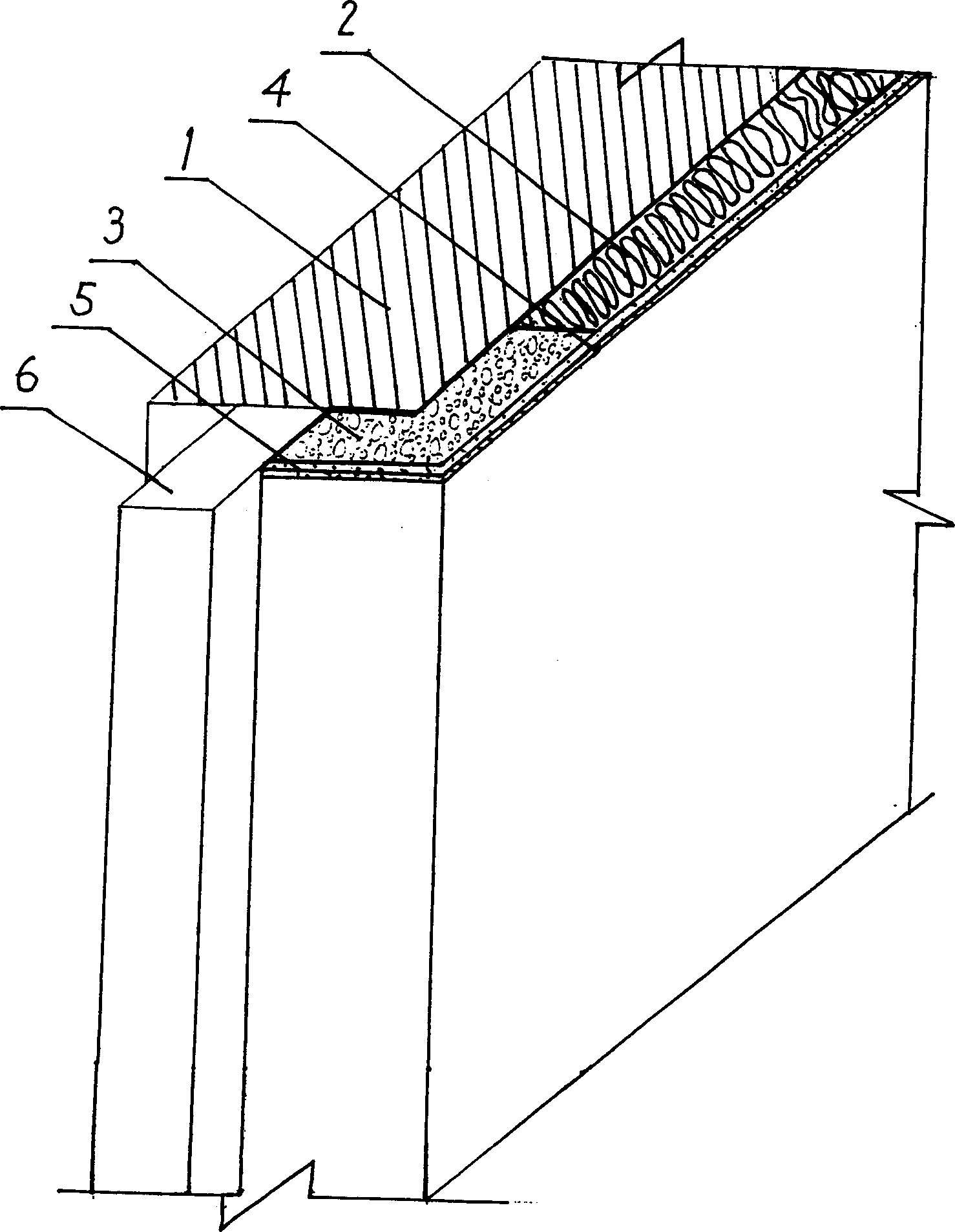

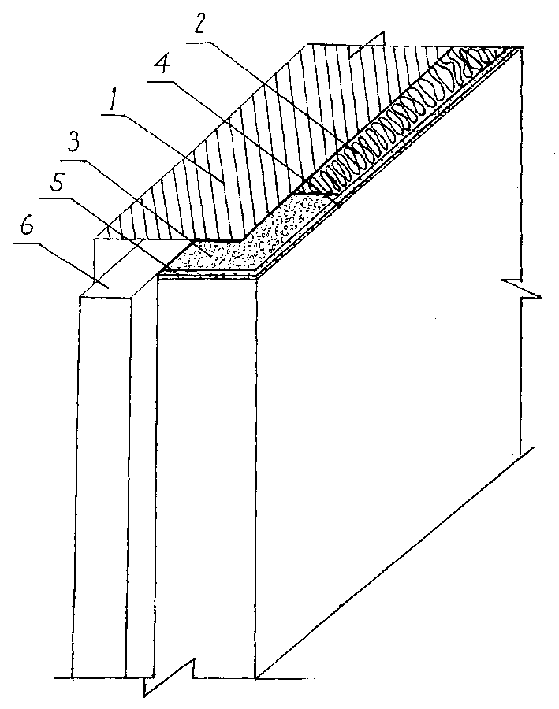

[0020] As shown in the figure, the base layer 1 of this thermal insulation wall can be concrete, brick or other blocks. In the larger area of the insulation layer and where it is easy to paste boards, use polystyrene boards 2 for construction; use polystyrene particles or polystyrene boards at doors, windows 6 or sides, corners, and parts that are difficult to carry out board construction. Particles mixed with perlite particles on-site preparation or pre-mixed thermal insulation plastering material 3 construction. Make these vulnerable parts both thermal insulation and high strength. The overcoat layer 4 can be an anti-cracking mortar layer with a built-in fiber mesh cloth 5, and the surface is covered with flexible putty and decorative paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com