Winding machine for row socket power harness and method for winding power harness

A technology for power cords and winding machines, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of uneven product appearance, excessive labor and time, and high labor intensity, and eliminate weak links. , the effect of saving labor and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

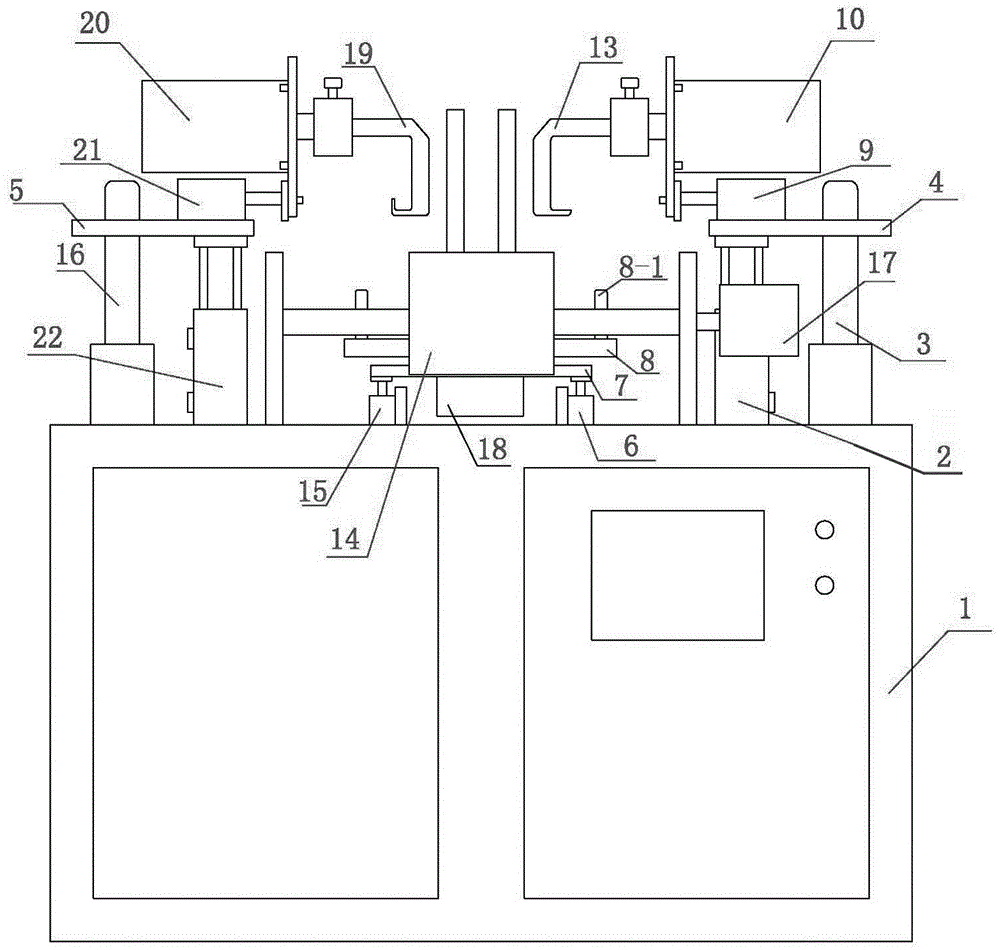

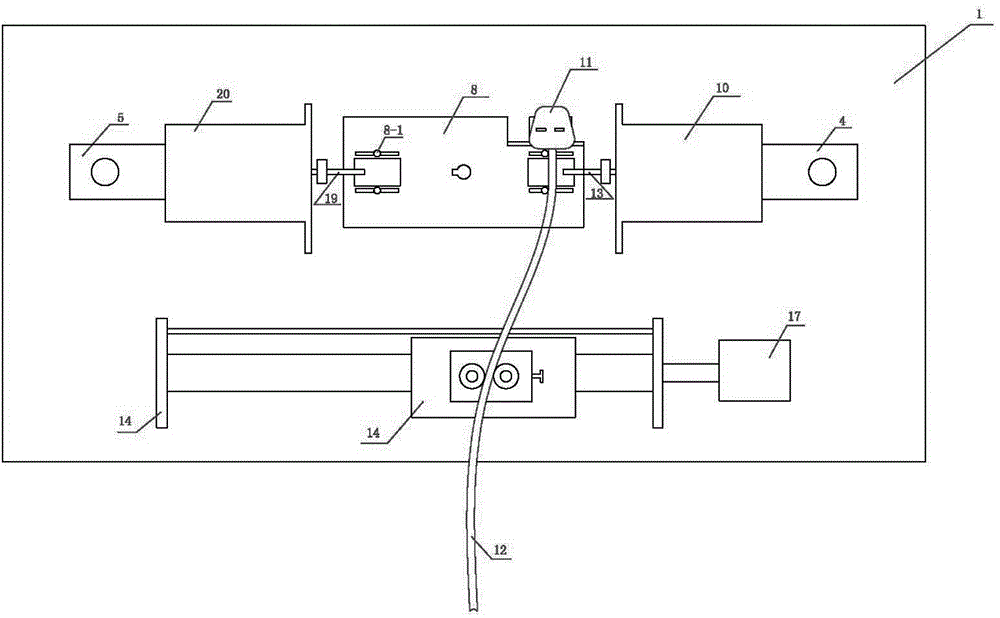

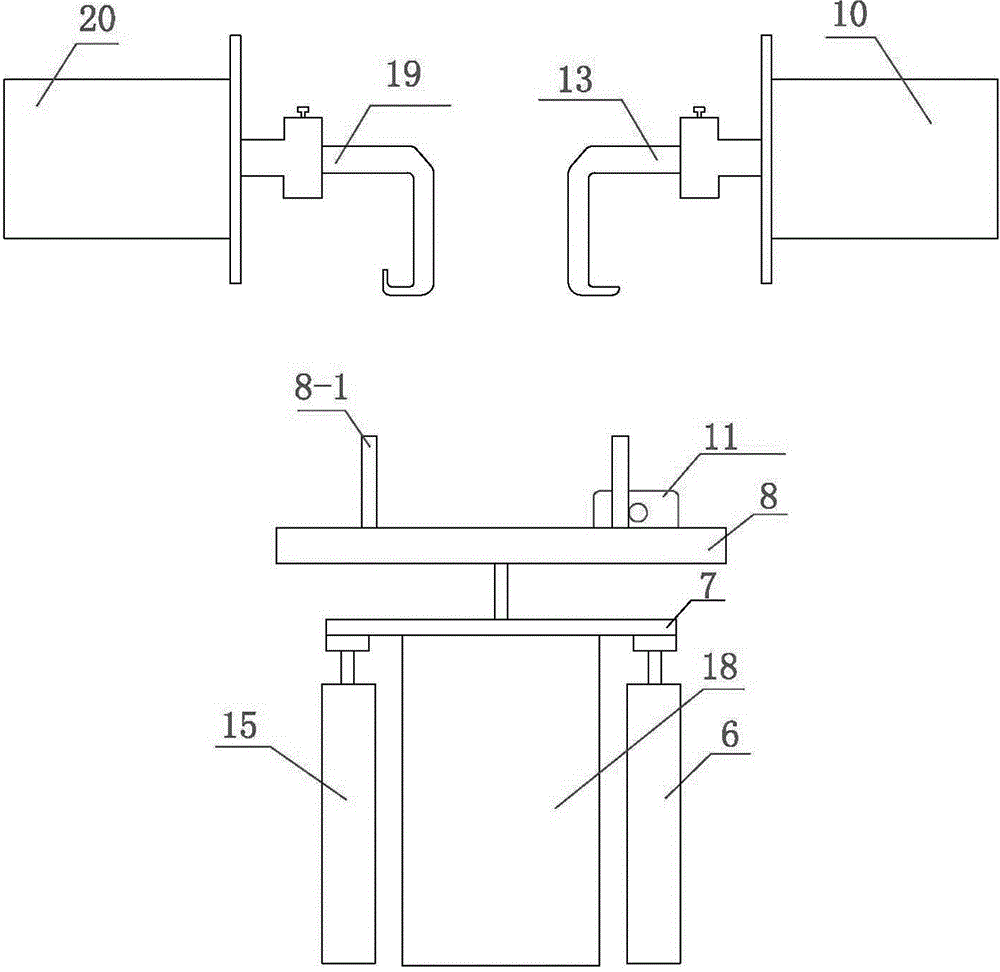

[0025] see figure 1 , figure 2 As shown, a row socket power wire harness winding machine consists of a chassis 1, a first cylinder 2, a second cylinder 9, a third cylinder 6, a fourth cylinder 15, a fifth cylinder 21, a sixth cylinder 22, and a first guide Column 3, first guide plate 4, second guide column 16, second guide plate 5, first stepping motor 10, second stepping motor 17, third stepping motor 18, fourth stepping motor 20. It is composed of the cable arranger 14, the program controller PLC and its control panel. On the left and right sides of the chassis 1, the first guiding column 3, the vertically placed first cylinder 2 and the second guiding column 16, the vertically placed 6th cylinder 22 are symmetrically installed; the horizontally placed second cylinder 9 The first guide plate 4 that slides on the first guide column 3 is fixedly connected with the piston of the first cylinder 2, and the first stepper motor 10 that is placed horizontally is fixedly connecte...

Embodiment 2

[0027] see Figure 3 ~ Figure 8 As shown, the method steps of winding the power wire harness with the row socket power wire harness winding machine of embodiment 1 are as follows:

[0028] (1) Fix the power cord plug 11 on the rotating disk 8 near the winding post 8-1 on either side, and the power cord 12 is positioned and routed through the cable straightener 14;

[0029] (2) The third stepping motor 18 drives the rotating disc 8 to rotate, and the power cord 12 is wound 2 to 10 times on the four winding columns 8-1 to become the main harness 12-1. The number of winding turns depends on the power cord 12 depends on the length of

[0030] (3) The first cylinder 2 and the sixth cylinder 22 act at the same time, and their pistons move downward, driving the first wire hook 13 and the second wire hook 19 to move downward to the predetermined position at the same time. At this time, the second cylinder 9 and the second cylinder 5. The cylinders 21 act at the same time, and their ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com