An annular multi-nozzle injection structure

A ring-shaped structure and multi-nozzle technology, applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve problems such as low performance, insufficient strength, and insufficient reliability, so as to avoid insufficient strength, improve ejection performance, and eliminate weak links Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

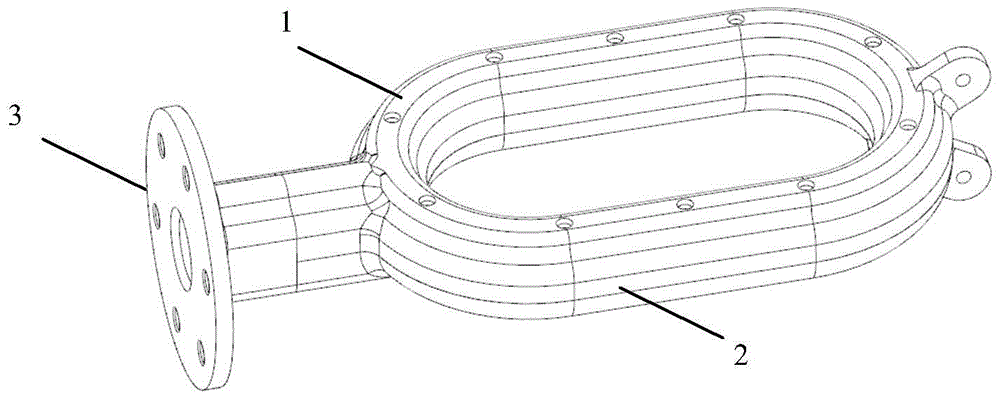

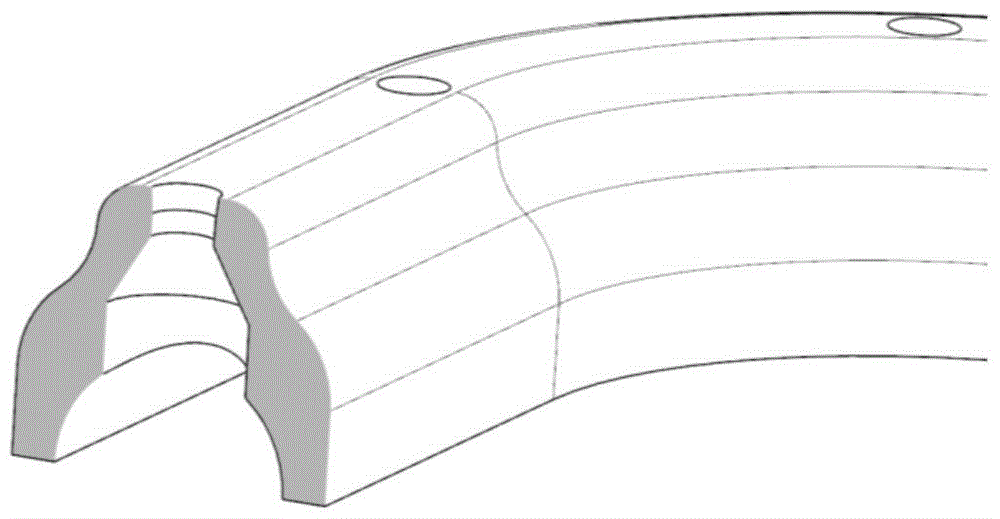

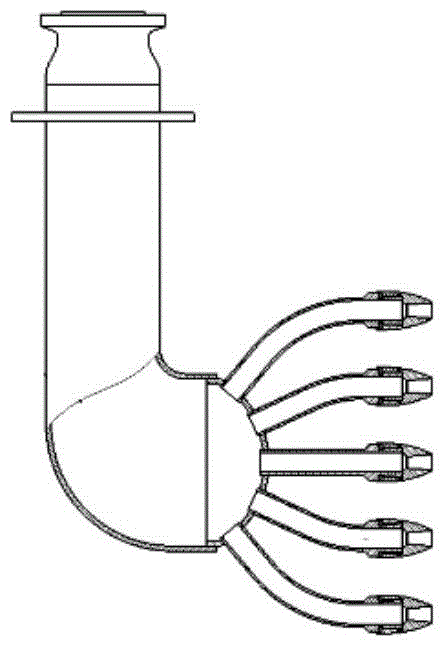

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description, please refer to the attached description of the description Figure 1-2 , the annular multi-nozzle ejector structure for ejectors of the present invention includes a nozzle ring 1, a rear sealing ring 2 and a flange joint 3, the nozzle ring 1 is an integrally formed multi-nozzle structure, the number and arrangement of the nozzles can be Set on the ring structure according to the performance requirements; the nozzle ring 1, the back sealing ring 2 and the flange joint 3 form a closed channel, and the three are integrally machined and then welded to provide a flow channel for the ejected air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com