Manufacturing process for electrode of cement based conductive composite material

A technology of conductive composite material and production method, applied in the direction of material resistance, connecting contact material, measuring resistance/reactance/impedance, etc., can solve the problems of inconvenient on-site application and many wiring, and achieve the elimination of weak links and high bonding strength. , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

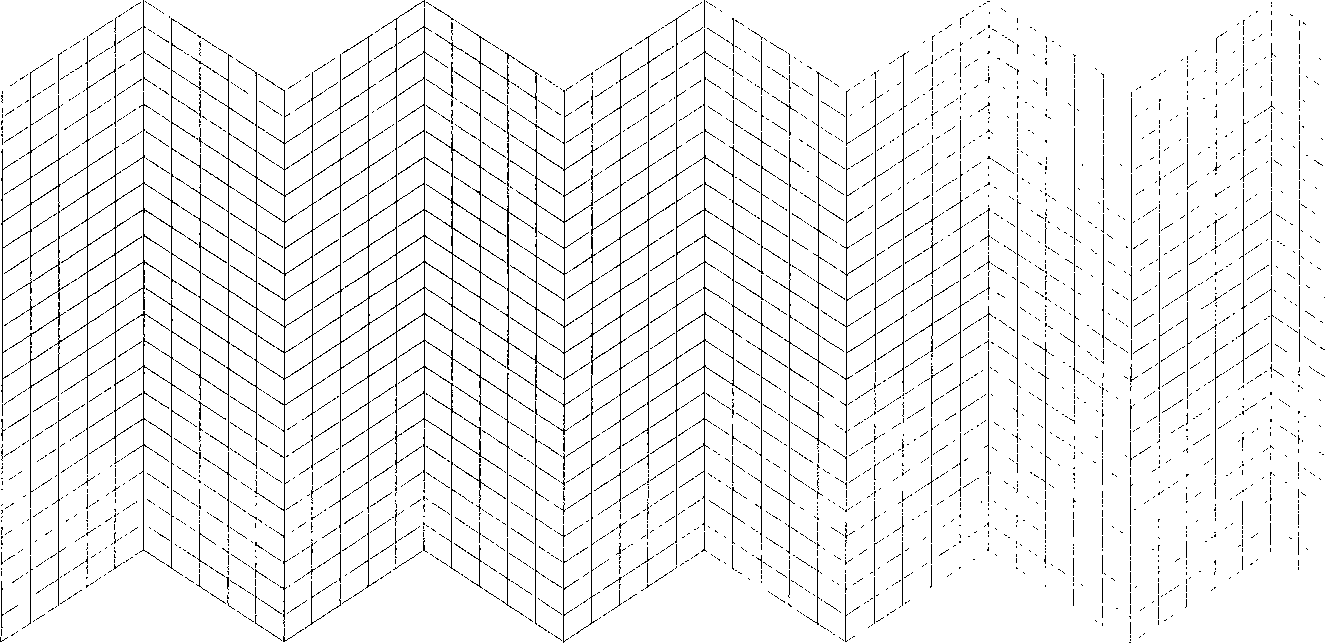

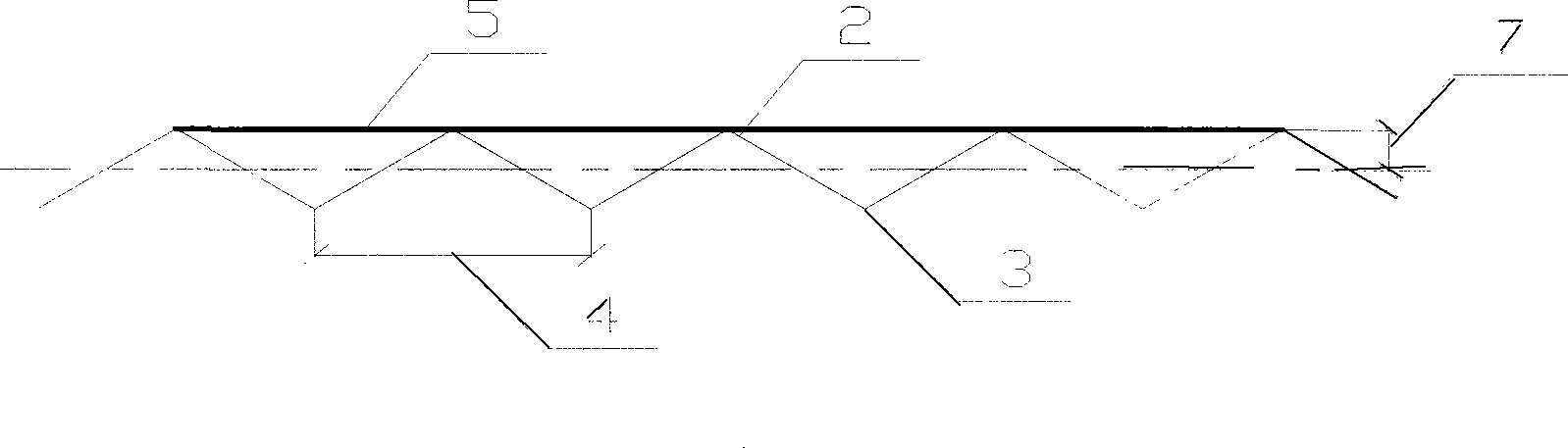

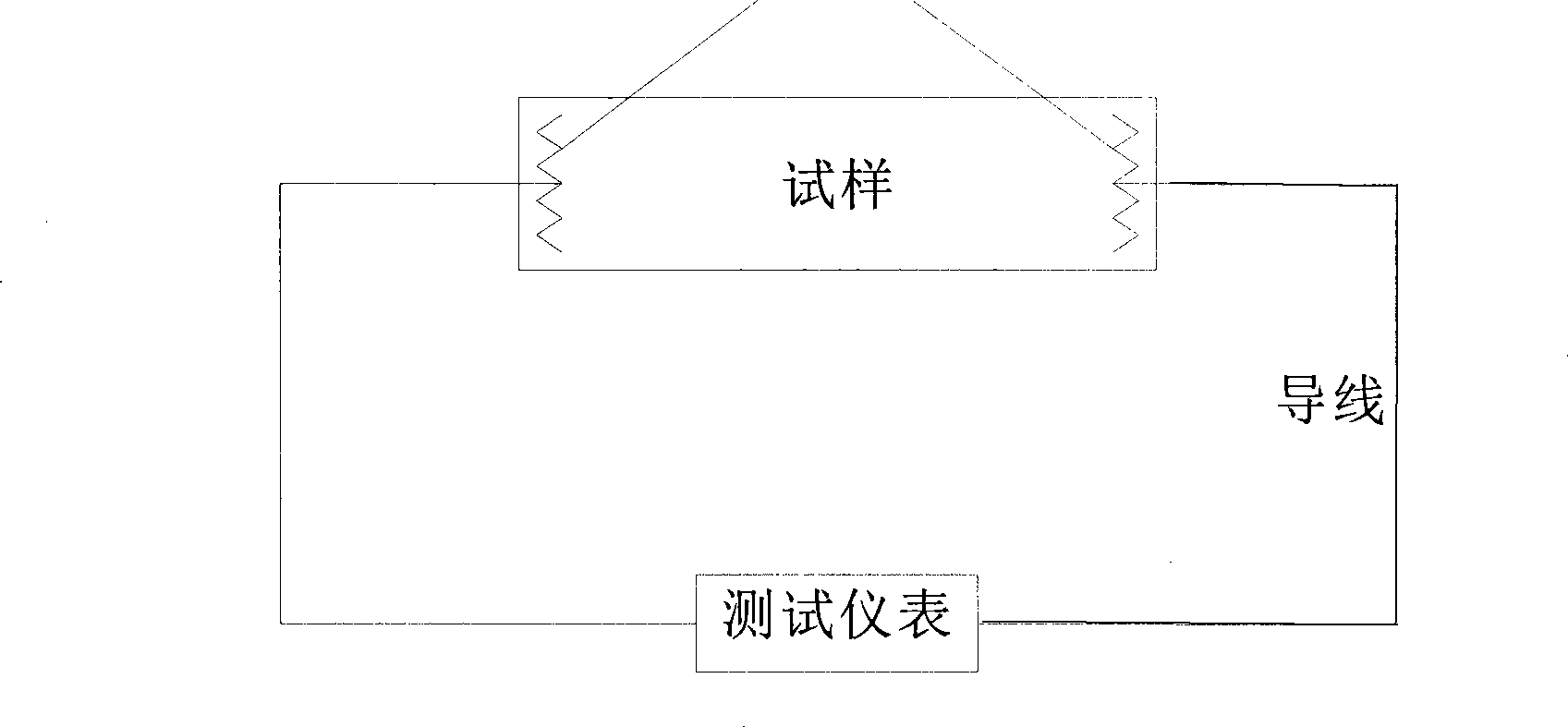

[0015] The present invention takes carbon fiber conductive cement mortar as an example to illustrate the manufacturing process of the electrode of the present invention. The size of the specimen is 100mm×100mm×50mm, the matrix material used is cement mortar, the conductive phase is PAN-based chopped carbon fiber, and the length is 3mm. According to the requirements of the test piece, the grid size of the plane stainless steel mesh is 5mm, and the projection size of the electrode is 40mm×80mm. Cut a flat stainless steel mesh strip with a width of 40mm, and press the flat stainless steel mesh strip into a triangular wave through the triangular waveform meshing gear. The angle of the peak 2 of the three-dimensional stainless steel mesh produced is 60 degrees, the period 4 is 10mm, and the amplitude of the three-dimensional stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com