Novel structural damage positioning method based on acoustic emission

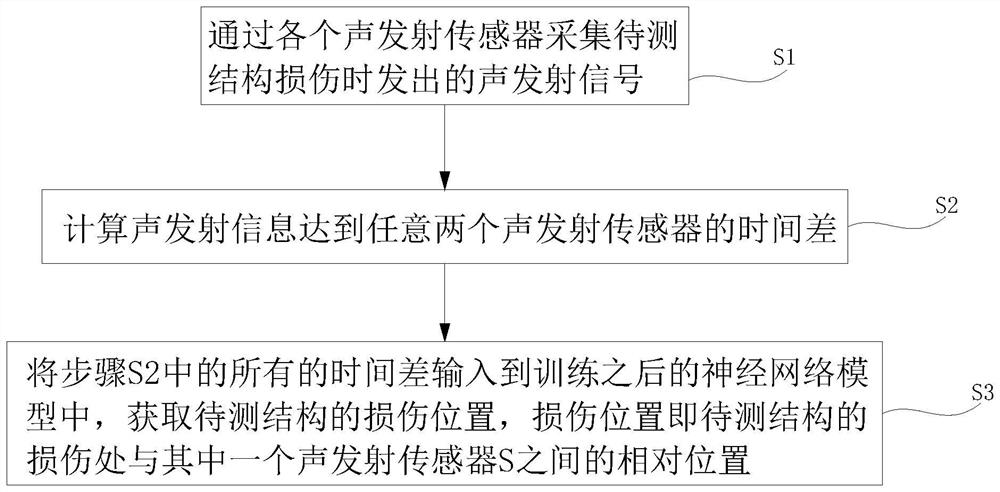

A technology for structural damage and acoustic emission, which is used in material analysis using sonic emission technology, processing response signals of detection, and material analysis using sonic/ultrasonic/infrasonic waves. , fatigue cracks and other problems, to achieve a stable damage location effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

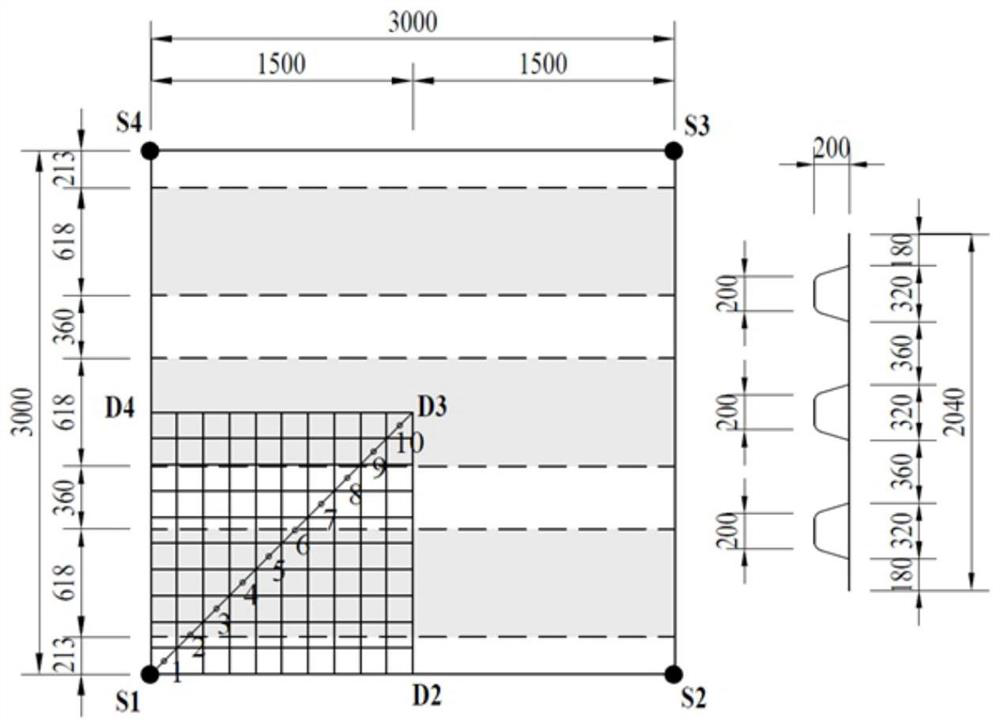

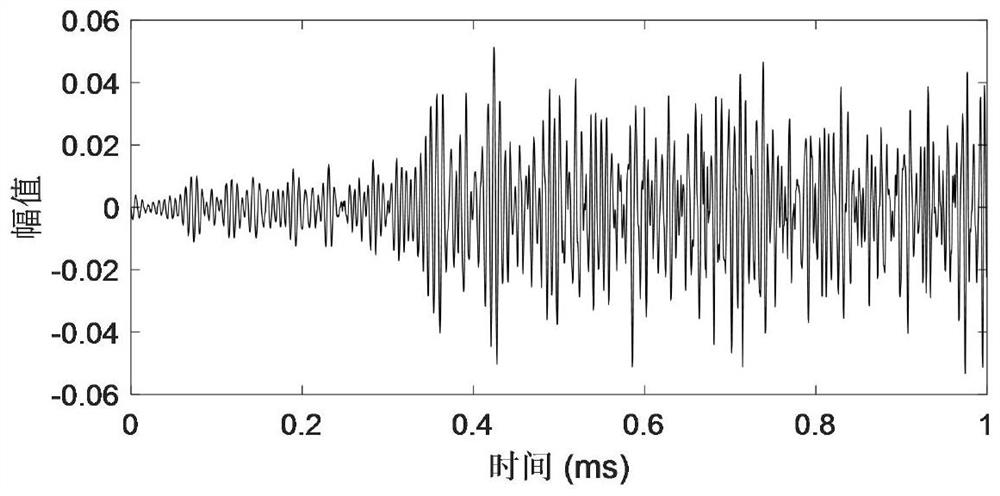

[0091] (1) The main content of the research in this embodiment is the damage location of the orthotropic steel bridge deck, in order to verify the acoustic emission source location based on empirical wavelet and long-short-term memory neural network proposed in this patent (the damage location of the structure is relative to the sensor position) method effectiveness and practicality. The experimental equipment used is a multi-channel acoustic emission data acquisition system. The operating frequency range of the acoustic emission sensor is 100-1000kHz. Four acoustic emission sensors are installed at the apex of the grid in the area to be measured using magnetic fixtures and coupling agents, and then connected to the data acquisition board through the preamplifier for acoustic emission data acquisition. , the amplification factor is set to 40dB, and the sampling rate is set to 5MS / s. The damage acoustic emission source is simulated by the standard lead breaking experiment, usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com