Board balance health-preserving chamber and board health-preserving method

A health care room and board technology, which is applied to other plywood/plywood appliances, humidity-adjusting wood, wood processing appliances, etc., to achieve uniform thermal stress, improve material yield, and reduce warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

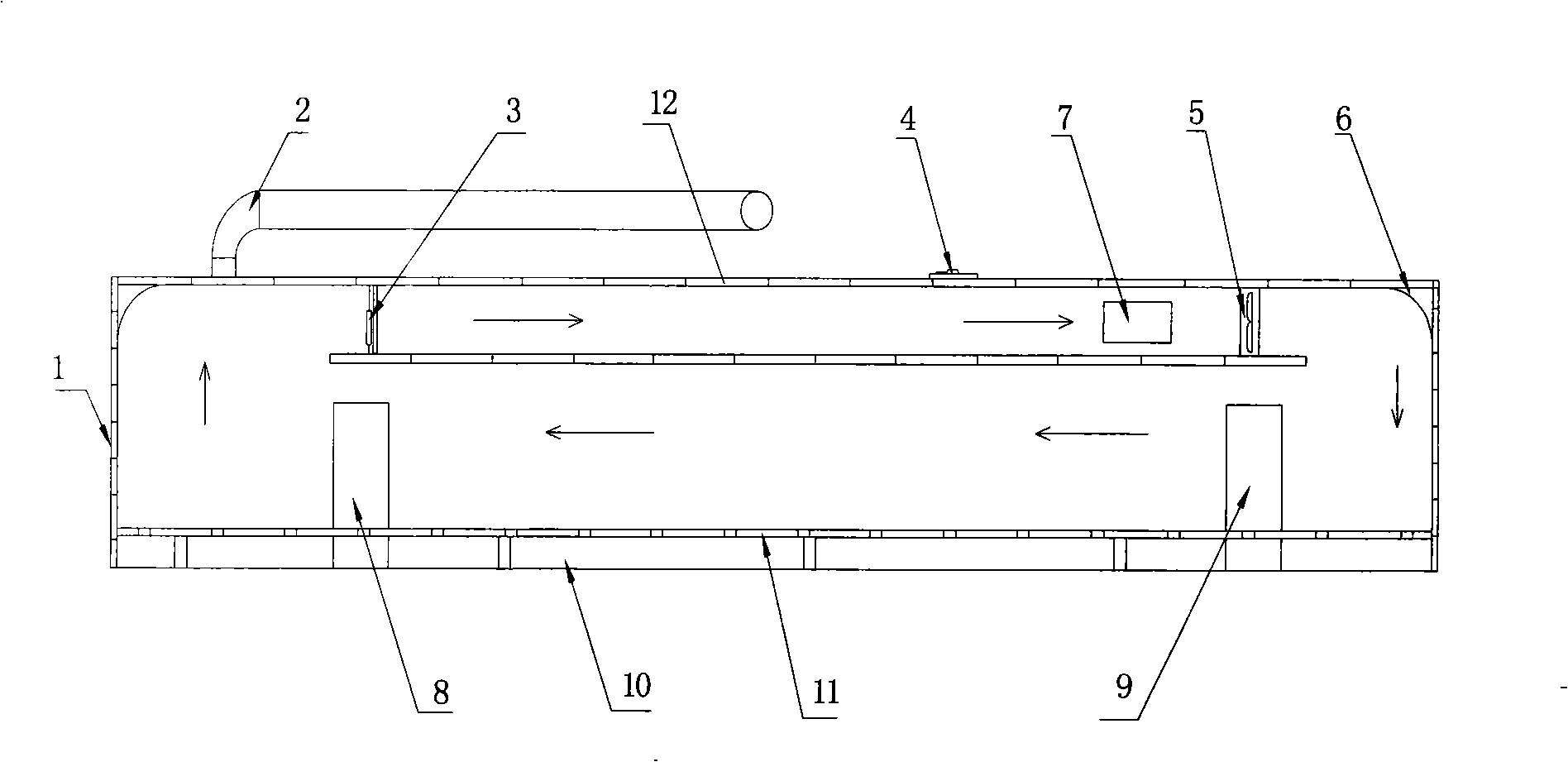

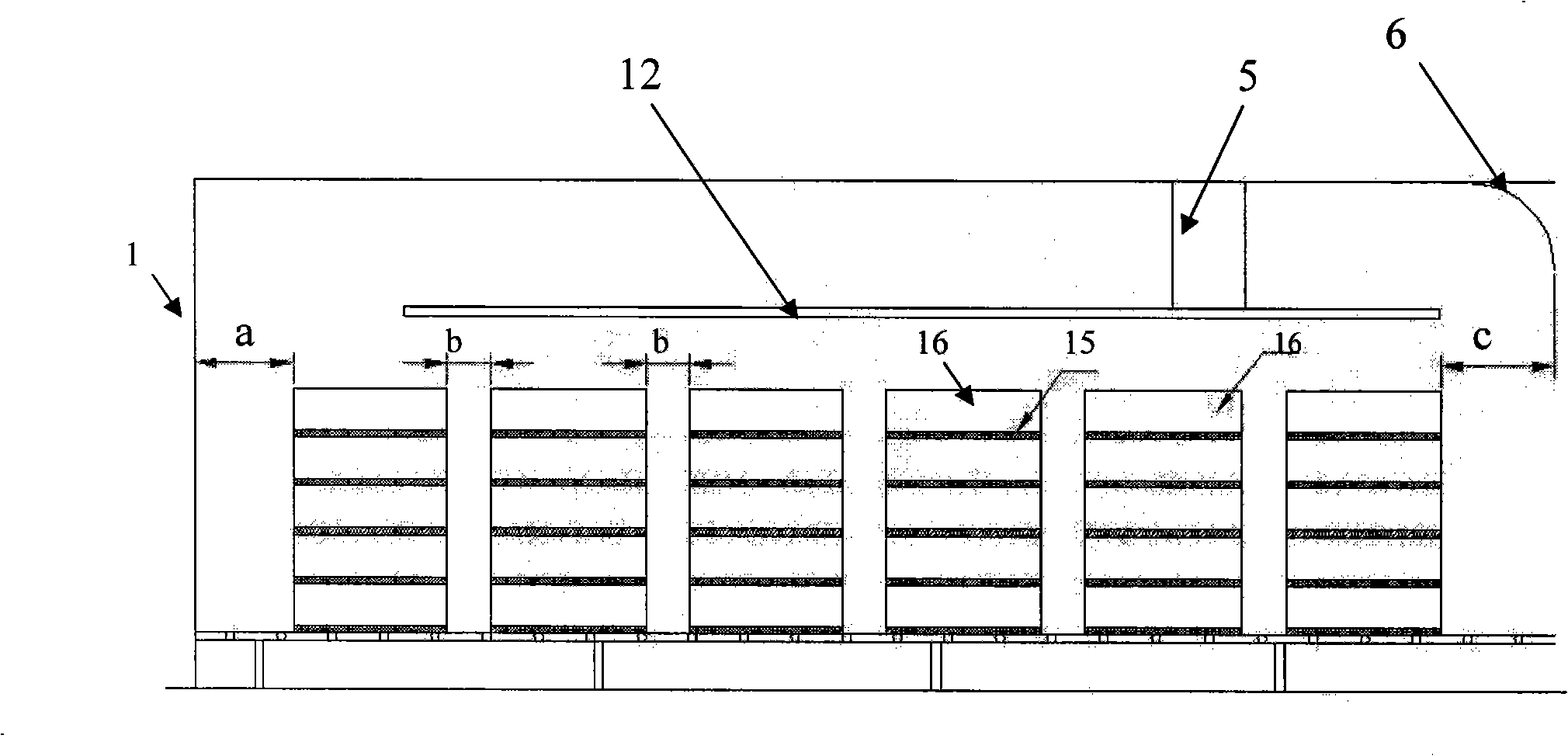

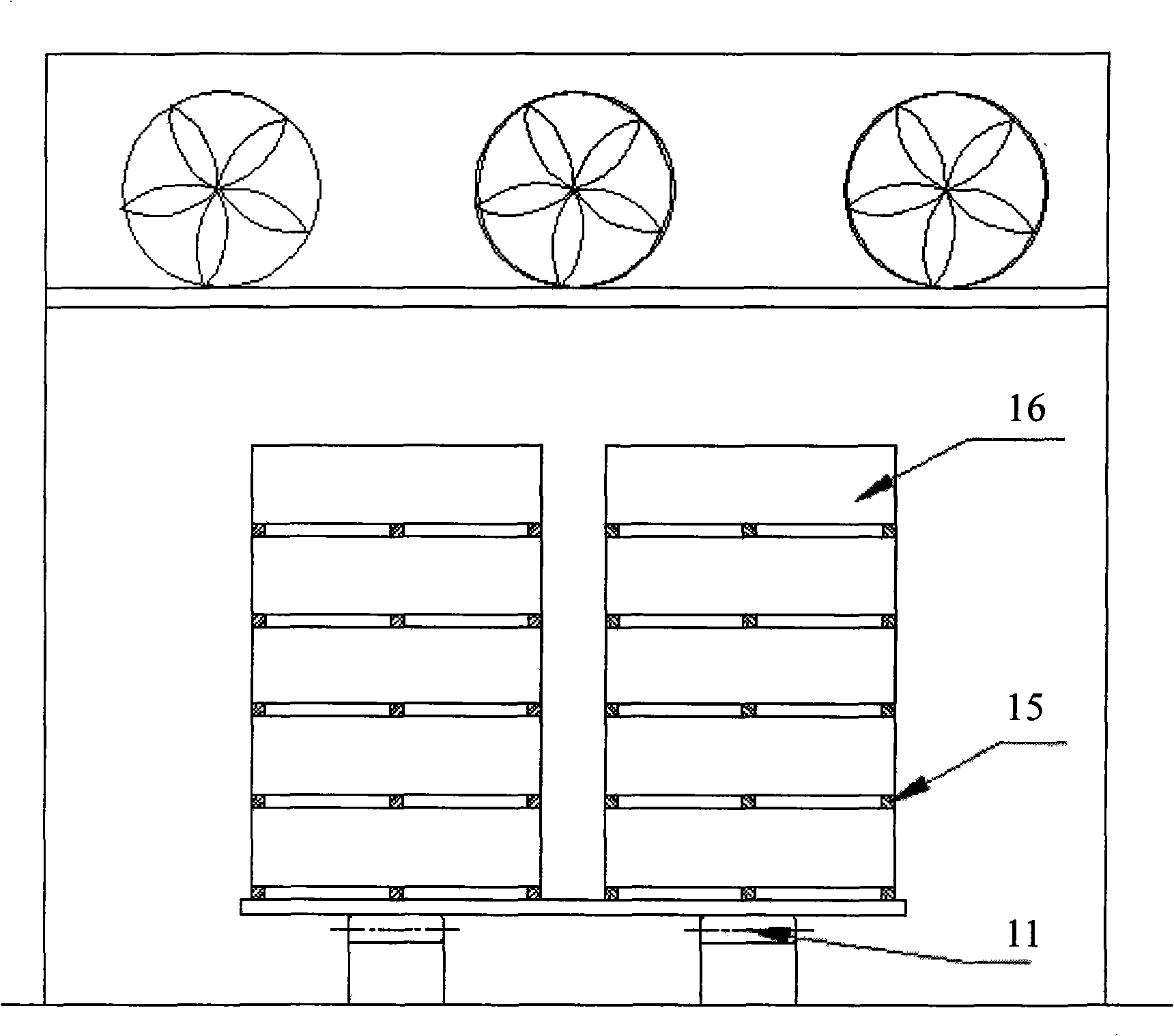

[0041] Such as figure 1 A dehumidifier 8, a humidifier 9 and an air conditioner 7 are arranged in the balanced health-preserving room shown in the plank, and a deflector 12 is arranged in the middle of the health-preserving room, and six axial flow fans 5 are arranged above the deflector 12. The ground of the health care room is provided with a rolling platform 10, and the rolling platform 10 is provided with a rolling platform 11 for placing plates, and the front and rear walls of the plate balance health room are provided with an up and down sliding shutter-type sealed door 1 for plates to enter and exit. A pneumatic air valve 4 is arranged on the top of the health care room, and a pneumatic shutter 3 is arranged above the deflector 12, and the pneumatic shutter 3 is located in front of the axial flow fan 5. A diversion arc 6 is arranged at the connection between the top of the health care room and the side wall. The deflector 12, the axial flow fan 5, and the pneumatic lou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com