Ground assembling and welding integral installation and construction technology for vaporization-cooling chimney

A technology for vaporizing cooling flue and cooling flue, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., to reduce risks, save equipment purchase costs, and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with the embodiments given by the accompanying drawings.

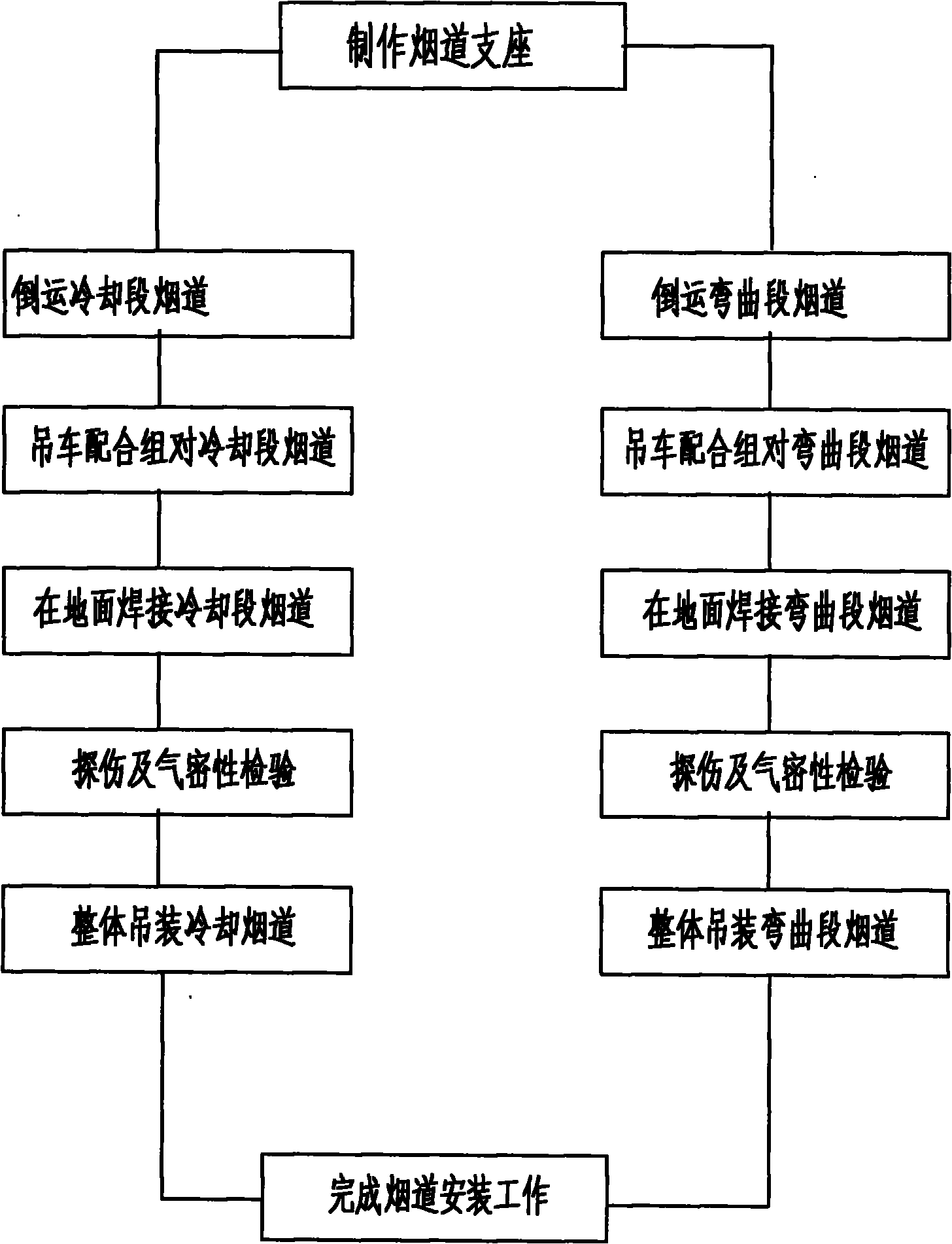

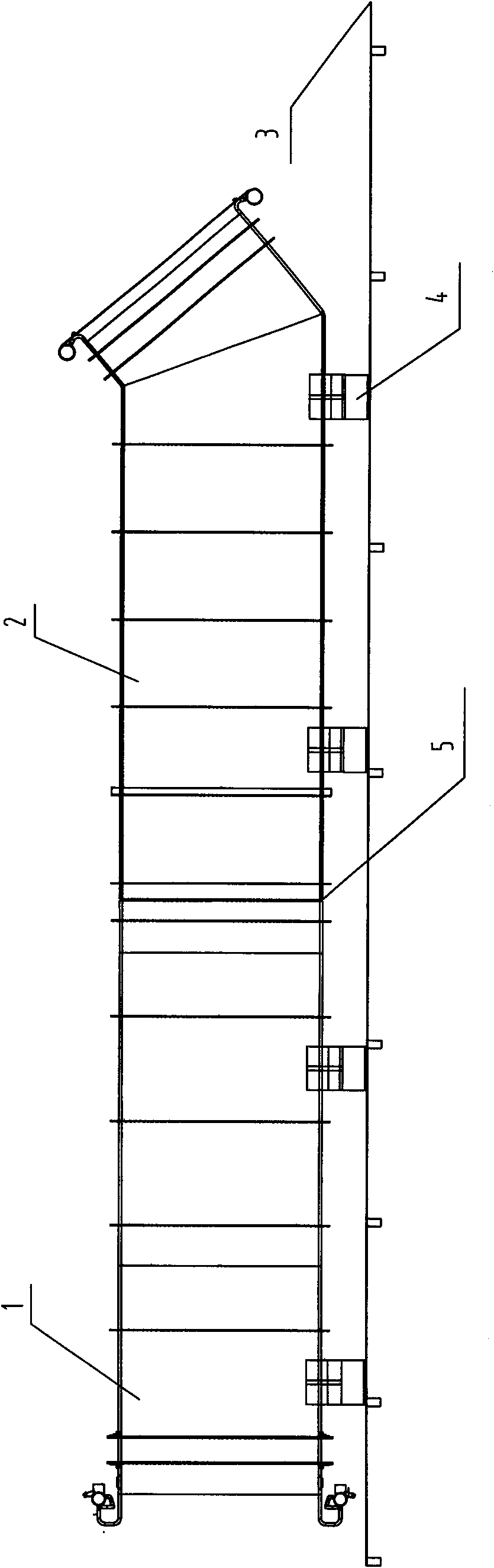

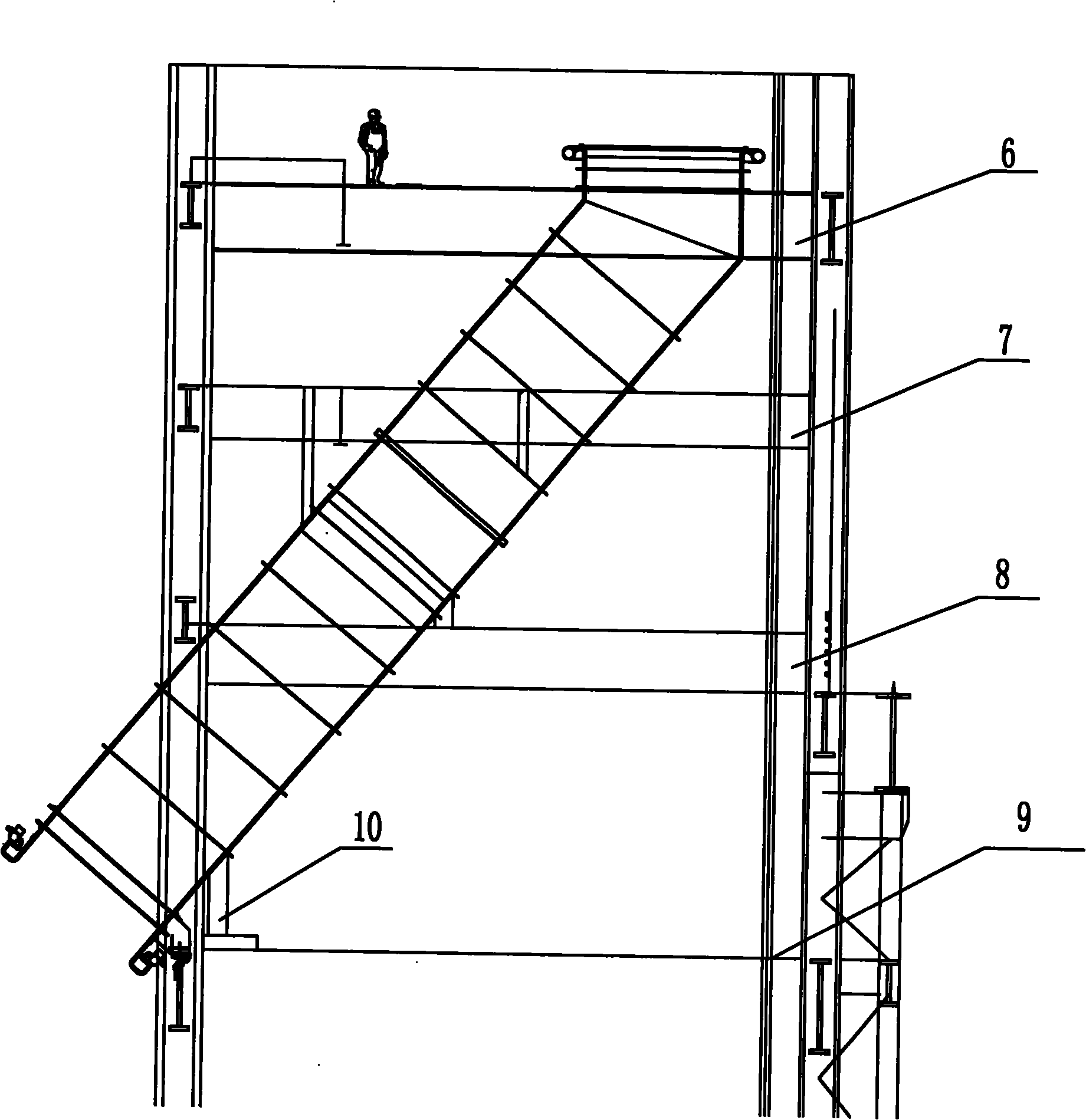

[0031] The cooling section flue of the large-scale converter vaporization flue described in this embodiment is divided into two sections, with a total length of 25506.4mm and a maximum diameter of Φ5540mm, wherein the length of the cooling section flue (A section) 1 is 12250mm, and the cooling section flue (B section) 2 The length is 13253.4mm; the flue of the curved section is divided into three sections, the maximum diameter is Φ5100mm, the width is 16565mm, and the height is 13515mm. The following are the overall installation and construction process steps of the vaporization cooling flue ground assembly butt welding of the present invention:

[0032] Step 1: Make the flue support:

[0033] Choose a spacious site, and after the ground is flattened and compacted, use 25mm steel plates to lay a 30m×6m steel platform 3 for assembling the flue. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com