Conductive thermal plastic dynamic vulcanizing silicone rubber and preparation method thereof

A dynamic vulcanization and silicone rubber technology, which is applied in the field of conductive thermoplastic dynamic vulcanized silicone rubber and its preparation, can solve the problem that the product fails to meet the requirements of use, there is no further research on the preparation of conductive thermoplastic dynamic vulcanized silicone rubber, and no dynamic vulcanization is used. Vulcanization advanced technology and other issues, to achieve the effect of large-scale industrial production, no toxic and volatile gas pollution, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

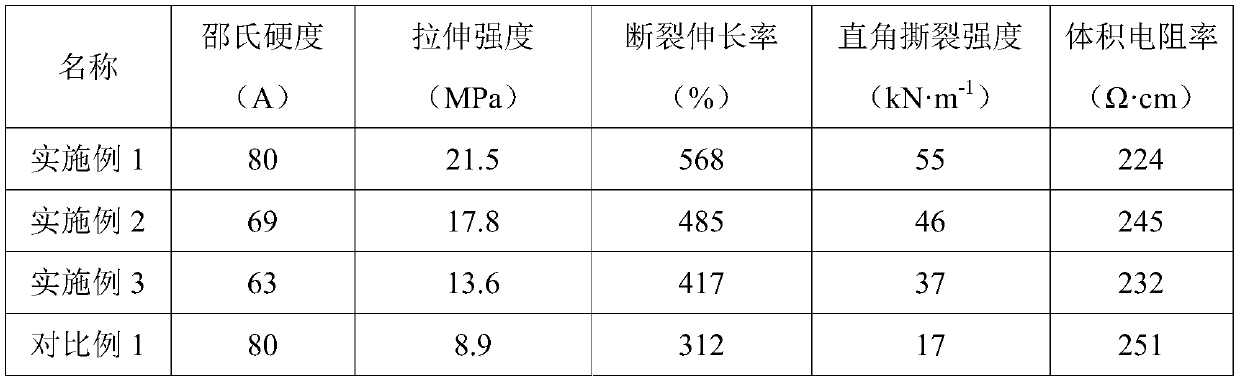

[0032] The silicone rubber compositions of Examples 1-3 and Comparative Example 1 are shown in Table 1, and the compositions stated in Table 1 are all parts by mass.

[0033] The silicone rubber composition of table 1 embodiment 1~3 and comparative example 1

[0034]

[0035] The preparation method of the conductive thermoplastic dynamic vulcanized silicone rubber of embodiments 1-3 is as follows:

[0036] Step 1) Add thermoplastic polyurethane elastomer (TPU), silicone rubber compound, compatibilizer, crosslinking agent, and conductive filler in the formula shown in Table 1 to the internal mixer, set the temperature to 170°C, and 40rpm, banburying time 5min, extrusion granulation to obtain the premix. The thermoplastic polyurethane elastomer used in Examples 1 to 3 is WHT-8285 (polyether) of Wanhua Chemical Company, the silicone rubber compound is EN-5150A of Dongjue Silicone Company, and the compatibilizer is EVA, cross-linked The agent is Dow Corning's hydrogen-contain...

Embodiment 4~6 and comparative example 2

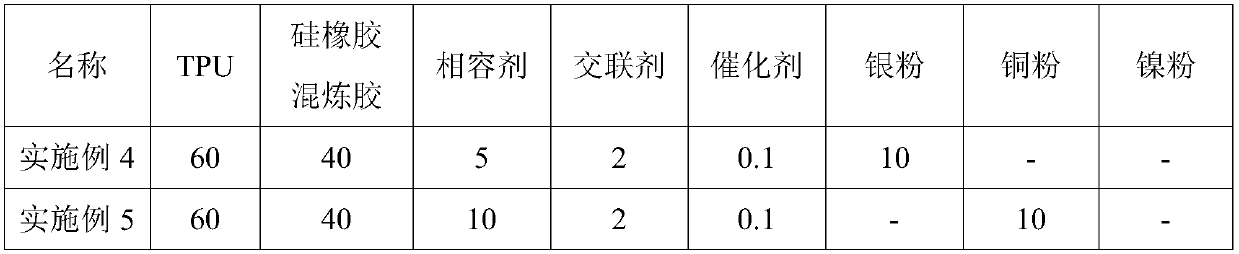

[0045] The silicone rubber compositions of Examples 4-6 and Comparative Example 2 are shown in Table 3, and the compositions stated in Table 3 are all parts by mass.

[0046] The silicone rubber composition of table 3 embodiment 4~6 and comparative example 2

[0047]

[0048]

[0049]The preparation method of the conductive thermoplastic dynamic vulcanized silicone rubber of Examples 4-6 is as follows:

[0050] Step 1) Add thermoplastic polyurethane elastomer (TPU), silicone rubber compound, compatibilizer, crosslinking agent, and conductive filler in the formula shown in Table 3 to the internal mixer, set the temperature to 180°C, and 60rpm, banburying time 7min, extrusion granulation to obtain the premix. The thermoplastic polyurethane elastomer that uses among the embodiment 4~6 is the S-185ALL (polyester) of Taiwan Kunzhong Company, and the silicone rubber compound is EN-8151 of Dongjue Silicone Company, and the compatibilizer is ethylene acrylic acid copolymer ( E...

Embodiment 7~10 and comparative example 3

[0059] The silicone rubber compositions of Examples 7-10 and Comparative Example 3 are shown in Table 5, and the compositions stated in Table 5 are all parts by mass.

[0060] The silicone rubber composition of table 5 embodiment 7~10 and comparative example 3

[0061]

[0062]

[0063] The preparation method of the conductive thermoplastic dynamic vulcanized silicone rubber of Examples 7-10 is as follows:

[0064] Step 1) Add thermoplastic polyurethane elastomer (TPU), silicone rubber compound, compatibilizer, crosslinking agent, and conductive filler in the formula shown in Table 5 to the internal mixer, set the temperature to 190°C, and 80rpm, banburying time 4min, extrusion granulation to obtain the premix. The thermoplastic polyurethane elastomer used in Examples 7-10 is WHT-8285 of Wanhua Chemical Company, the silicone rubber compound is EN-5150A of Dongjue Silicone Company, and the crosslinking agent is hydrogen-containing silicone oil of Dow Corning Company, mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com