Primer-free polyurethane glass cement and preparation method thereof

A glass glue, polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of increasing the coating primer process, increasing the cost of use, and the storage period being too short, avoiding the need for The effect of foaming phenomenon, saving process and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

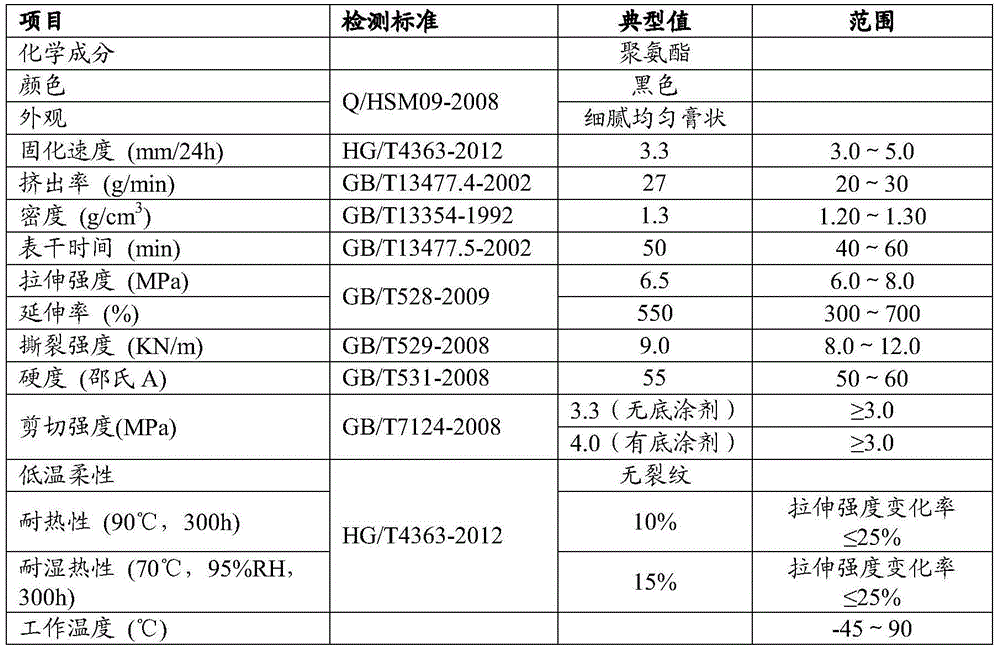

Image

Examples

Embodiment 1

[0030] A primer-free polyurethane glass glue, which is composed of the following components in percentage by weight: 19.75% dioctyl phthalate, 38% polyurethane prepolymer, 18% calcium carbonate, 5.0% spherical Silica powder, 2.8% titanium dioxide, 1.0% calcium oxide, 10.0% carbon black, 5.0% meteorological silica, 0.05% dibutyltin dilaurate and 0.4% glycidyl ether oxypropyl trimethoxy Silane KH560.

[0031] The preparation method is as follows, based on the percentage of the total weight of the primer-free polyurethane glass glue to be prepared, the steps are as follows:

[0032] (1) Add 19.75% dioctyl phthalate and 38% polyurethane prepolymer that have been dehydrated into the reactor, and stir in vacuum for 30 minutes;

[0033] (2) Put 18% calcium carbonate, 5.0% spherical silicon micropowder, 2.8% titanium dioxide, 1.0% calcium oxide and 10.0% carbon black into the reactor, and stir in vacuum for 30 minutes;

[0034] (3) Continue to add 5.0% meteorological silica in the r...

Embodiment 2

[0042] A primer-free polyurethane glass glue, which is composed of the following components in percentage by weight: 19% dioctyl phthalate, 35% polyurethane prepolymer, 17% calcium carbonate, 6% spherical Silica powder, 2.5% titanium dioxide, 3% calcium oxide, 10.9% carbon black, 6% meteorological silica, 0.03% dibutyltin dilaurate and 0.57% glycidyl ether oxypropyl trimethoxy Silane KH560.

[0043] The preparation method is as follows, based on the percentage of the total weight of the primer-free polyurethane glass glue to be prepared, the steps are as follows:

[0044] (1) Add 19% dioctyl phthalate and 35% polyurethane prepolymer that have been dehydrated into the reactor, and stir in vacuum for 30 minutes;

[0045](2) 17% of calcium carbonate, 6% of spherical silicon micropowder, 2.5% of titanium dioxide, 3% of calcium oxide and 10.9% of carbon black that have been dried in advance are put into the reactor, and stirred in vacuum for 30 minutes;

[0046] (3) Continue to a...

Embodiment 3

[0049] A primer-free polyurethane glass glue, which is composed of the following components in percentage by weight: 19% dioctyl phthalate, 36% polyurethane prepolymer, 19% calcium carbonate, 5% spherical Silica powder, 2.5% titanium dioxide, 1% calcium oxide, 12.17% carbon black, 5% meteorological silica, 0.03% dibutyltin dilaurate and 0.3% glycidyl ether oxypropyl trimethoxy Silane KH560.

[0050] Its preparation method is as follows:

[0051] (1) Add 19% dioctyl phthalate and 36% polyurethane prepolymer that have been dehydrated into the reactor, and stir in vacuum for 30 minutes;

[0052] (2) 19% of calcium carbonate, 5% of spherical silicon micropowder, 2.5% of titanium dioxide, 1% of calcium oxide and 12.17% of carbon black dried in advance are put into the reactor, and stirred in vacuum for 30 minutes;

[0053] (3) Continue to add 5% meteorological silica in the reactor, stir for 30min;

[0054] (4) Finally, add 0.03% dibutyltin dilaurate and 0.3% glycidyloxypropyltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com